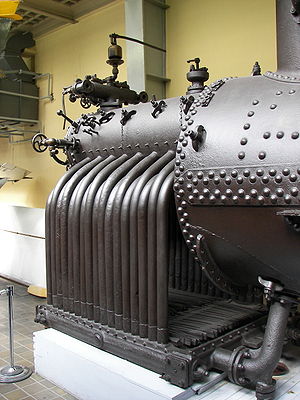

Brotan kettle

The Brotan boiler is a steam boiler for locomotives in which the structural advantages of a tubular boiler and a shell boiler have been combined. Its name comes from the Austrian engineer Johann Brotan , who received the patent for this design in 1902. Was the background of the development, in the early days of the steam locomotive almost entirely of copper existing firebox to replace and reduce maintenance costs.

history

Copper was an expensive material in Austria-Hungary . In addition, in Carniola and Dalmatia , for example, only sulphurous coal was available, which clogged the copper fire boxes too much. The production techniques for standing boilers made of steel at that time, which withstood sulfur-containing coal better, were not yet mature enough.

Brotan's construction dispensed with a double-walled standing kettle. Instead of the fire box, there was a narrow layer of trouser-shaped riser pipes that led into a preheater drum. The tubes formed the side walls of the standing kettle, which resulted in a relatively large direct heating surface. As a transition to the long boiler , its smoke and heating pipes and the preheater drum were installed in a wall. Front and back, where no risers were the Brotan boiler was with fireclay lined ™ stones.

The water ran through large pipes from the long boiler to a water chamber under the standing boiler, which was designed like a frame. The water chamber received the risers and surrounded the grate . The steam collected in the preheater drum and the boiling water was held back.

In January 1901, the freight locomotive 47.54 of the kk state railways (kkStB) was equipped with a Brotan boiler as the first machine . Due to good results, further locomotives of the series kkStB 4 , kkStB 47 , kkStB 53 and kkStB 73 followed . The Austrian series kkStB 310.300 received Brotankessel ex works due to a lack of copper. Other countries also installed Brotan boilers in various locomotives.

As the steel fire rifles matured enough to replace the copper fire rifles, fewer and fewer Brotan kettles were built.

The many water pipes initially tended to leak and the fireclay lining to cracks. Nevertheless, Brotan boilers were installed in new locomotives, especially in Czechoslovakia until the annexation by the so-called "Third Reich".

Because of the shortage of copper and steel in World War II, people in the Greater German Reich remembered the Brotan kettle. At the instigation of Gerhard Degenkolb , who chaired the main committee for rail vehicles, the locomotive factory Floridsdorf (WLF) equipped the 50 3011 and 50 3012 with a boiler of this type and delivered it in October 1942. After the war, both locomotives received normal boilers from the DB , as there was no maintenance or operating experience whatsoever with the Brotan boiler in Germany. The locomotives 42 0001 and 42 0002 were also given a Brotan boiler in 1943 by the WLF. Although the construction program in 1943 envisaged 1,800 BR 42 with a Brotan boiler (650 of which with a condenser tender) and 2,500 with a stud boiler, all other locomotives of the 42 series were built with stud boilers. These two locomotives later kept their Brotan boiler with the DB until they were retired, which, however, had already been completed for almost the entire DB class 42 by October 28, 1954.

literature

- Weisbrod, Barkhoff: The Steam Locomotive - Technology and Function Part 4 Special Designs of German Steam Locomotives . Eisenbahn-Journal, reprint Verlagsgruppe Bahn GmbH, Fürstenfeldbruck 2003, ISBN 3-922404-10-3 .