Medium pressure

The mean effective pressure is a calculation variable to assess the efficiency and the gas exchange of reciprocating piston engines regardless of the engine displacement or size. It is the quotient of the mechanical work performed by the engine during one work cycle (in Newton meters, N · m) and its displacement (in cubic meters, m 3 ). The meter in the newton meter and one meter in the cubic meter are shortened, so that at the end there is an indication in newtons per square meter (N · m −2 = Pa ), i.e. a pressure. This pressure is usually given in bar (1 bar = 100,000 N · m −2 ). The mean effective pressure cannot be measured like the compression pressure, for example , but can only be determined by calculation. In simplified terms, the accelerator pedal in the vehicle can be viewed as an actuator for the medium pressure.

There are two types of medium pressure:

- The effective mean effective pressure can be calculated from the output torque or as a quotient from the work done on the crankshaft during a complete work cycle and the displacement :

- ( is the number of work cycles per revolution: 0.5 for four-stroke engines and 1 for two-stroke engines . In the case of rotary engines, due to the four- stroke working cycle, the working volume is also calculated, which is calculated from the chamber volume as follows:, where the number If the mean effective pressure of the rotary engine is to be calculated from the chamber volume instead of the working volume , this should be assumed.)

- The indicated mean effective pressure corresponds to the indicated work (see also volume work ) on the piston.

- In slow-running engines ( steam engines ), a writing measuring device ( indicator ) could be connected to the working cylinder and the content of the positive area circumscribed by the pressure curve could be planimized (measured) in its diagram in order to determine the size of the indicated work. Nowadays the indicated mean pressure is determined with electronic measuring devices .

The quotient of the two aforementioned mean pressures is called the mechanical efficiency and is a dimensionless measure for all mechanical losses:

Air ratio and mean pressure

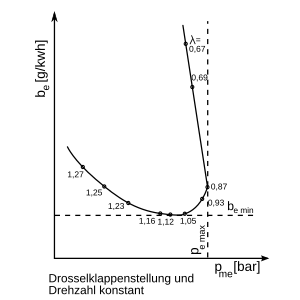

diagram for the gasoline engine

mixture, bottom left "lean", top right "rich"

Gasoline engine

Otto engines are operated at an air ratio of around . This enables exhaust gas cleaning with the three-way catalytic converter. A lambda probe in front of the catalytic converter measures the oxygen content in the exhaust gas and forwards signals to the control unit of the mixture regulator. The task of the mixture regulator is to keep the air ratio close to through the injection quantity . The most efficient operation occurs with a slightly lean mixture of . The highest torque (medium pressure) is achieved with a rich mixture of approx . This is also where the highest ignition speed and reaction speed of the gasoline-air mixture are set. Regular combustion is no longer guaranteed beyond the ignition limits ( for gasoline engines) (combustion misfires).

Diesel engine

Diesel engines, on the other hand, work with a lean mixture of up to . The highest torque (medium pressure) is normally not achieved with a rich mixture of approx. Because of the soot limit. At part load, the air ratio is greater than and reaches values of up to about 5 when idling.

Typical values for medium pressure

| Motor type | comment | ||||

|---|---|---|---|---|---|

| Series engines | Diesel engine | Charged | Two-stroke marine diesel engine | 20th | z. B. MAN 5G45ME |

| High-performance car engine | 31.5 | z. B. BMW B57 | |||

| 2 liter turbo diesel | 20.5 | z. B. VW EA189 | |||

| Free sucking | 1.9 liter naturally aspirated diesel | 8.5 | z. B. VW EA188 | ||

| Gasoline engine | Charged | High-performance car engine | 29 | z. B. Mercedes-Benz M 133 | |

| Free sucking | Car engine, 4 valves per cylinder | 11.5 | z. B. Mazda 2-liter MZR | ||

| Car engine, 2 valves per cylinder | 10.5 | z. B. BMW M20 B20 | |||

| Motorcycle engine, 4 valves per cylinder | 13.5 | z. B. Kawasaki Ninja ZX 600 G | |||

| Racing engines | Gasoline engine | Charged | Formula 1 engine, 1980s | 57 | Honda F1 (1987), maximum mean pressure |

| Free sucking |

Formula 1 engine 3.0 l ten-cylinder |

15th | |||

If the effective mean effective pressure is plotted against the specific fuel consumption as a function of the air ratio of the engine, the fish-hook curve is obtained for gasoline engines .

See also

Individual evidence

- ↑ Technikhomepage.de - The thermodynamics of the internal combustion engine

- ↑ Honda Power Curves. (PDF; 999 kB) GrandPrixEngines.co.uk, accessed on December 2, 2015 (English).

literature

- Richard van Basshuysen, Fred Schäfer: Handbook Internal Combustion Engine Basics, Components, Systems, Perspectives. 3rd edition, Friedrich Vieweg & Sohn Verlag / GWV Fachverlage GmbH, Wiesbaden, 2005, ISBN 3-528-23933-6

- Wolfgang Beitz, K.-H. Küttner (Hrsg.): Taschenbuch für den Maschinenbau / Dubbel 15th edition, Springer Verlag, Berlin, Heidelberg, New York, 1983, ISBN 3-540-12418-7

![{\ displaystyle p _ {\ text {m}} \, [\ mathrm {bar}]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/379975bb8bff24b7a9afb2ca7dd719cbc1ef9455)