Winkler generator

The Winkler generator is a fluidized bed gasifier developed by Fritz Winkler , which was originally used for the autothermal gasification of lignite to produce synthesis gas .

Procedure

The ammonia and methanol production processes developed by BASF required large quantities of hydrogen and synthesis gas, which could be provided with the Winkler generator. The process, which was registered for a patent in 1926, was first put into operation in the Leuna factory.

It is a direct current process that is carried out at atmospheric pressure and in which the ash is discharged dry. The ash partially falls to the bottom of the reactor and is carried away by a screw conveyor. Another part is discharged from the reactor with the gas stream with unburned coal particles. In contrast to other processes such as Lurgi pressure gasification , there are no tars or phenols that have to be separated.

The resulting raw gases vary in their composition depending on the lignite used and the operating conditions. The hydrogen content is between 35 and 46%, the carbon monoxide content is around 30 to 40%. Most of the residual gas consists of carbon dioxide and a small part of methane (1 to 2%).

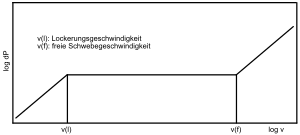

The process is characterized by a relatively high velocity between the particles and the gas. The fluidized particles, which are referred to as the fluidized bed or bed, often collide with one another and with the reactor wall, which leads to intensive mixing of the particles. The fluidized bed behaves like a fluid after the loosening speed is exceeded. This has the advantage of a relatively homogeneous temperature distribution in the bed with good heat and mass transfer.

The pressure loss over the bed remains constant within wide limits and corresponds roughly to the total weight of the suspended particles. If the particle velocity is too high, ie the free floating velocity v (f), particles are discharged from the reactor.

The apparatus is constructed in such a way that the fluidized bed is located in the lower area of the cylindrical, refractory-lined generator. Air or oxygen are fed into the reactor at the same time as water vapor. The generator is also fed continuously via a screw conveyor. A typical reactor throughput is in the order of about 40 tons of lignite per hour, corresponding to a gas production of about 60,000 cubic meters.

Individual evidence

- ↑ The Haber-Bosch process and the age of fertilizers ( memento from July 20, 2012 in the web archive archive.today )

- ↑ Hydrodynamics of the fluidized bed: Fluidic behavior and appearance of the fluidized bed

literature

- F. Asinger : Methanol, chemical and energy raw material . Akademie-Verlag, Berlin, 1987, ISBN 3-05500341-1 , ISBN 978-3-05500341-7 .