Abbe's comparator principle

The Abbe comparator principle is a fundamental principle that mechanical length measuring devices should be based on in order to achieve a high level of measurement accuracy. It states that the scale should be aligned in the measuring direction (in a line) with the test item (the measuring section). It was named after Ernst Abbe , who was the first to describe it.

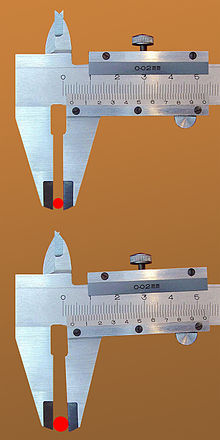

If the distance to be measured on the test object and the scale (material measure) of the measuring device are not in one line, tilt errors (so-called tilt errors of the first order ) can occur in the measuring device ( see also: Vernier calipers ). These depend on the play of the caliper perpendicular to the direction of movement and cannot be avoided in principle.

If the distance to be measured and the scale of the meter, as in the ironing micrometer , arranged in alignment, fewer errors occur due to tilting. The only thing is that the distance to be measured can be slightly rotated against the measuring axis (a normal between the touch surfaces of the device). These so-called second-order tilt errors are significantly smaller than the first-order tilt errors .

The length comparator is a practical application of the principle .