Order rhythm system

The ordering rhythm procedure is part of the ordering policy . The order policy itself belongs to the area of procurement and subsequently to materials management . A distinction is made between order point procedures and order rhythm procedures.

The ordering rhythm procedure is one of the consumption-oriented ordering procedures . This is a date-based order triggering in which an order is placed within constant time intervals ( i.e. cyclically), with the order quantity either being fixed or varying. After the fixed order interval has expired, reorders will be made in any case, provided that there has been a movement in stock.

Application in practice

The order rhythm procedure is used

- if the delivery rhythm is specified by the supplier.

- if the company's production cycle allows missing materials to be ordered only at certain advance notice periods.

Order rhythm policy

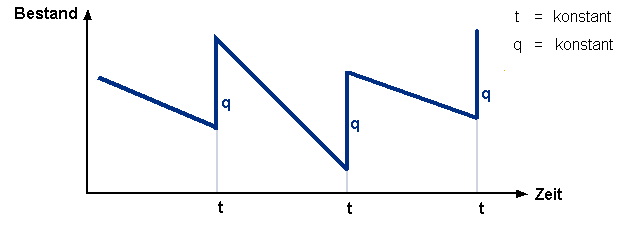

Order rhythm-lot size policy

This procedure is also called (t, q) policy , as the order is placed within fixed order periods (t0) and for a fixed order quantity (q0).

application

This policy makes sense when demand remains constant over a longer period of time.

advantages

Since less coordination is required, costs can be saved in this area.

There is planning security for certain quantities.

disadvantage

Inadequate inventory control can lead to shortages in the event of irregular demand . This leads to shortage costs such as lost profits, contractual penalties, excessive procurement costs, costs of machine downtime or loss of goodwill . In addition, with a fixed order quantity, there is the risk of excessive stocks, which in turn can cause storage costs (for example, increased space costs due to increasing space requirements, inventory costs, increased testing costs or increasing interest and capital costs, spoilage, loss of quality). The higher the capital commitment , the higher the assessed risk .

Formula:

P: order point = reorder point D: avg. Consumption / unit of time; B: lead time; U: review time; S: safety stock;

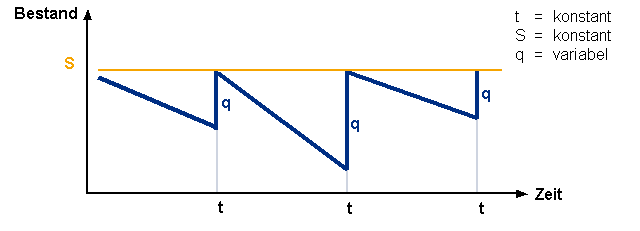

Order rhythm and stock level policy

With the (t, S) policy , orders are placed within fixed order intervals (t0), but with variable order quantities (qi). After t0 time units, so much is ordered that the warehouse is filled up to its capacity limit S , taking into account the normal delivery time and the remaining stock . This level S must be sufficient to compensate for fluctuations in demand, since the inventory is not controlled between the periods.

application

This policy is useful if, for example, several items are purchased from the same supplier, as the process enables coordinated ordering in this case.

advantages

By setting a capacity limit, the maximum stock is limited, which leads to a reduction in storage costs. Since the storage material is kept at a predetermined level S, both interest costs and storage and handling costs can be reduced. Likewise, the assessed risk is decimated by tying up limited capital.

disadvantage

In an irregular demand, due to the fixed order intervals stockouts occur to shortage costs may result.

Compared to the order point procedure

The advantage over the order point procedure is that it is more likely that collective orders can be created for materials of the same type , for which better conditions can be achieved under certain circumstances . Another advantage is the lower control effort, since no stock checks are carried out during the ordering interval.

The disadvantage is that the consumption in the time between two inspection appointments has to be bridged in addition to the consumption during the replenishment time and the inventory has to be increased .

In this respect, it can also be explained that the order rhythm system is found more frequently in retail . There are short lead times through coordinated deliveries from central warehouses possible.

See also

- Order

- Order time

- Order quantity

- Order point procedure

- Warehousing

- Procurement logistics

- Materials management

Literature sources

- Oskar Grün: Industrial materials management. In: Marcell Schweitzer (Ed.): Industriebetriebslehre. 2nd Edition. Munich 1994, pp. 447-568, ISBN 3-8006-1755-2

- Hans-Christian Pfohl: Logistics systems : Business basis, 5th edition Berlin Heidelberg 1996, ISBN 354060314X

- Waldemar Toporowski: Logistics in retail : Optimal warehouse structure and order policy of a branch company. Heidelberg 1996, ISBN 3790809632