DC purging

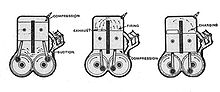

The uniflow scavenging is of flushing in the two-stroke engine . During the gas exchange, the fresh gas flows parallel to the cylinder axis in one direction, the inlet and outlet are at opposite ends of the cylinder. In contrast to reverse purging , the gas flow is not deflected at the cylinder wall.

Designs

DC purging can be implemented in two ways:

- Via exhaust valves in the cylinder head and intake slots near the bottom dead center. The outlet opens in front of the inlet slots (asymmetrical control diagram).

- Without valves; two pistons work with a common combustion chamber. The “hot” piston releases the outlet openings and the “cold” piston the inlet openings.

- In opposed piston engines , both pistons run against each other in a cylinder; they act on one or two crankshafts via connecting rods. With only one crankshaft, long double connecting rods and a yoke over a piston or two connecting rods connected by rocker arms per piston are required.

- In double-piston engines, the neighboring cylinders are parallel. The combustion chamber is at one end of the cylinder, the scavenging slots at the other. There is either a crankshaft and forked or split connecting rods or two counter-rotating crankshafts.

properties

Advantages:

- Good washing effect (high degree of washing and catching )

- The outlet can close before the inlet (asymmetrical control diagram ), which is a prerequisite for supercharging in a two-stroke engine.

- Piston rings can rotate freely, which improves the service life because of the contact with the scavenging slots.

Disadvantage:

- Increased effort compared to simple slot-controlled two-stroke engines

- Larger overall height compared to four-stroke engines and slot-controlled two-stroke engines, as two-stroke engines build longer due to the large piston height.

- High thermal load on the outlet, as it is only exposed to hot gases and this with every stroke. Special measures must therefore be taken for cooling. This design-related effect is found in a similar form in the Wankel engine .

- In opposed piston engines, the piston on the exhaust side is subjected to particularly high thermal loads.

Examples

The exhaust valve design is used in modern supercharged marine diesel engines . With supercharged engines, the outlet closes before the inlet. An older example of this type is the two-stroke naturally aspirated diesel from Cummins in the Krupp Titan (1963–1968).

The Napier Deltic series engines are among the successful double-piston engines with exhaust ports and direct current purging .

Individual evidence

- ^ Richard van Basshuysen, Fred Schäfer (ed.): Handbook internal combustion engine . 8th edition. Springer Fachmedien, Wiesbaden 2017, ISBN 978-3-658-10901-1 , 10.3.1 Flushing method.