Metal hose

A metal hose is a flexible metallic conduit element . There are two types of metal hoses, which differ in construction and application: wound hoses and corrugated hoses. The former are characterized by high mechanical strength (e.g. tensile and tear strength), corrugated hoses are flexible pipe elements which, due to their material, can withstand high pressures and offer maximum tightness. They are also characterized by corrosion resistance and pressure tightness even under extreme conditions such as aggressive sea water or extreme temperatures such as B. in space or for the transport of frozen liquid gas. They are particularly suitable as heat and cold conducting pipe elements.

In the history of technology spanning more than a hundred years, other flexible pipe elements have developed from the metal hose, such as the metal compensator, the metal bellows or semi-flexible and flexible metal pipes. In Germany alone there are around 3500 patents relating to metal hoses.

origin

Technically speaking, the first metal hose was a so-called wound hose. It was invented in 1885 by the Pforzheim jewelry manufacturer Heinrich Witzenmann (1829–1906) together with the French engineer Eugène Levavassèur. The goose gargle chain served as a model, a piece of jewelry that was manufactured on the principle of interlocking metal bands. The original shape of the metal hose was made from an S-shaped profiled band, the profile of which interlocks when the screw-thread is wound. This was not done with a positive fit, but between the hooked profiles there was a cavity. A rubber thread was then inserted into this for sealing.

The result was a metallic, permanently mobile and dense steel body of any length and any diameter with great mechanical strength. For France it was patented on August 4, 1885 with the patent number 170 479, in Germany on August 27, 1885 with the German Imperial Patent No. 34 871.

Between 1886 and 1905, Heinrich Witzenmann developed a large number of other noteworthy profiles for hose production that are still technically valid today. In 1894 he applied for a patent for the double metal hose, two metal hoses wound on top of each other in opposite directions. Further modifications compared to the first form consisted of various materials and other materials for the thread seal, especially rubber, textile thread, asbestos and wire.

An important variant of the metal hose goes back to the Frankfurt inventor Siegfried Frank. In 1894 he patented the rolling of a screw-type corrugation (helical corrugation) into a rigid smooth tube. Heinrich Witzenmann had already undertaken attempts in this direction a few years earlier, but did not lead them to patentability. It was not until the 1920s and 1930s that the trained hotel clerk Albert Dreyer from Lucerne managed to create a satisfactory ring corrugation in order to manufacture corrugated metallic hoses.

Further development

Emil Witzenmann, son of Heinrich Witzenmann, developed a form of metal hose in 1909 in which he did without any sealing thread made of rubber, textile fibers or asbestos. The tape edges do not overlap, but lie against each other and are seamlessly welded. In 1920 Emil Witzenmann invented the metal hose expansion joint. The basis was the double-walled, welded, corrugated metal hose (with a wrapped protective jacket) with radial mobility. 1929 succeeded in manufacturing metal bellows. These were designed at the same time - but independently of one another - by Dreyer in Lucerne. Metal bellows are created by rolling annular corrugations into a drawn or welded smooth tube. In 1946 Albert Dreyer developed a multi-walled expansion joint that was also designed for axial movements: the axial expansion joint.

Wrapped hose

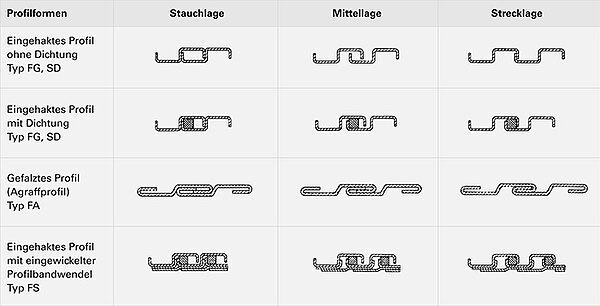

Wrapped hoses consist of turns that are loosely hooked into one another. This makes them extremely flexible. They are manufactured in two variants: with a hook profile or with a folded profile such as the Agraff profile. Both variants offer high flexibility due to the mobility of the profiles. However, this results in them not being one hundred percent tight. Therefore, they are often used as insulating or protective tubes around an inner tube.

Layout and function

Coiled hoses are created by helically winding a cold-rolled , profiled metal strip onto a mandrel, the helically rotating turns being connected to one another in a displaceable manner by the type of profiling. This principle of the sliding connection of the profile windings enables the great flexibility and mobility of the metal wound hose. The starting materials used are mostly strips made of galvanized steel, stainless steel and brass, which can also be chrome-plated or nickel-plated.

Properties of wrapped hoses

Wrapped hoses can withstand enormous tensile and transverse pressure loads and are characterized by their high torsional strength, as well as chemical and thermal resistance. Due to their construction, however, wound hoses do not achieve 100% tightness.

Types of wrapped tubes

The properties are determined by several factors of the metal hose: profile shape, band dimensions, material and, if applicable, the type of seal. Wrapped hoses are available in round and polygonal cross-sectional shapes. In automotive engineering, wound hoses with metallic sealing are mostly used. By inserting a sealing thread made of cotton, rubber or ceramic during the winding process into a specially profiled sealing chamber, greater tightness can be achieved. Wrapped hoses are also coated with PVC or silicone for maximum tightness. The profile shapes range from the simple hook profile to the high-strength Agraff profile.

Areas of application of wound hoses

Coiled hoses are often used as a flexible, temperature and aging-resistant element in exhaust technology, especially in trucks and special vehicles, such as. B. tractors. Also as a protective hose for light guides and electrical lines in fiber optics or measurement / control technology. As miniature tubes with a diameter range of 2.0–0.3 mm, they are also used in medical technology, such as endoscopy technology.

In addition, wound hoses are used as suction and conveying hoses for smoke, chips, granules, etc. Wrapped hoses are also suitable as protective hoses for corrugated hose lines to prevent overbending or as a liner (guide hose inside a corrugated hose) to optimize the flow conditions.

The group of wound metal hoses also includes the bendable arms - usually called goosenecks - which are made from the combination of a round wire helix with a triangular wire wound over it. They can be bent in any direction and remain freely in any position. Applications are movable holders for lamps, magnifying glasses, microphones, etc.

Corrugated hose and corrugated pipe

Depending on the area of application, the same product is called either a corrugated hose or a corrugated pipe.

Corrugated hoses are pressure and vacuum tight. The permissible operating pressures for small dimensions reach up to 380 bar (with 3-fold burst pressure safety); the compressive strength of large dimensions is lower for technical reasons. In the stainless steel version, a temperature resistance of up to approx. 600 ° C is guaranteed, depending on the pressure load, and even higher values are possible with special materials. Corrugated stainless steel hoses down to –270 ° C can be used in the low temperature range.

Layout and function

Corrugated hoses are also used to absorb movements in the form of thermal expansion and vibrations. They are used, for example, as a filling hose, for the (temporary) connection of devices to permanently installed pipe networks and now more often for the connection of solar collectors .

The starting material is seamless or longitudinally welded, thin-walled tubes into which shafts are formed mechanically or hydraulically using special tools. Corrugated hoses are absolutely tight and are used to conduct liquids and gases under pressure or as a vacuum line. Due to the seamless manufacturing process, they can usually withstand higher pressures than wrapped hoses.

Types of corrugated hoses

Corrugated hoses are manufactured in two basic types, which differ in the type of corrugation: annular and helical corrugation . In spiral corrugation, a mostly right-handed spiral runs with a constant gradient over the entire length of the hose. The annular corrugation, on the other hand, has a large number of parallel waves of equal spacing, the main plane of which is perpendicular to the hose axis. Corrugated hoses have decisive advantages over helically corrugated hoses:

- If installed correctly, they are free from harmful torsional stresses in the event of pressure increases (pressure surges)

- Due to the profile shape, they connect evenly to connection fittings.

This increases process reliability when assembling and operating the hose line. Therefore, annularly corrugated hoses are now the most widespread with a few exceptions.

Manufacture of corrugated hoses

The manufacture of a corrugated hose line begins with the forming of the initial strip from the coil into a longitudinally welded smooth tube. The continuous butt welding is carried out with high-precision gas shielded welding processes . There are two forming processes for the subsequent corrugation process:

- The hydraulic corrugation process with expansion of the pipe from the inside out. It is used to manufacture corrugated hoses.

- The mechanical corrugation process, on the other hand, is used to manufacture both ring and helically corrugated hoses. Usually several profiled pressure rollers are arranged offset around the pipe in such a way that when rotating around the pipe they roll in the desired wave profile from the outside to the inside. Both corrugation processes lead to material consolidation and thus increase the pressure and fatigue strength of the corrugated hoses.

In addition, a special process for the production of helically corrugated hoses is used, which is closely related to the production of wound hoses: The starting strip is given a wave-shaped profile in the longitudinal direction. This profile strip is then wound in a helical manner and the overlapping turns are tightly welded by a helically encircling seam. If necessary, the waving is followed by braiding (see below). The hose runs through a braiding machine with revolving wire spool supports, the so-called bobbins.

As a result, the wire bundles are both placed helically around the hose and alternately arranged above and below one another, so that a round braid with typical crossings is formed. The hose line is complete as soon as the fittings are installed. Production-related tests are also part of the manufacturing process. These range from the incoming inspection of the raw material to a measurement, leakage and pressure test of the finished hose assembly.

flexibility

The elastic behavior of the wave profile is relevant for flexibility. When bending, the waves stretch apart on the outer curve, while at the same time they are compressed in the inner curve. The flexibility, bending behavior and pressure resistance of corrugated hoses depend on the choice of profile shape. While the flexibility increases when the profile height is increased and the corrugation distance is reduced at the same time, the pressure resistance is reduced. The often desired semi-flexible bending behavior is achieved through flat profiles. Depending on the application, special application-specific profile shapes are implemented.

Compressive strength and flexibility can also be changed by varying the wall thickness. Reducing the wall thickness increases flexibility, but reduces the compressive strength of the hose.

Special designs

Miniature hoses with diameters of just a few millimeters are highly flexible and at the same time extremely resistant. With a special coating, they are used in minimally invasive surgery. Versions with an inner liner (see below) and special connections are used for laser or optoelectronic applications. The smallest diameters of miniature tubes are 1.8 mm.

Areas of application for metal hoses

The most common areas of application of modern technology with its high demands on heat and cold-carrying power systems are:

- Electrical industry and mechanical engineering as protective hose for electrical cables or light guides

- As suction, conveying and coolant hose, e.g. B. in the promotion and transport of liquid gas

- Automotive industry as an exhaust hose for vibration decoupling in exhaust systems

- As a ventilation hose in technical building equipment

- Steel industry

- Measurement and Control Technology

- Medical technology

- Aerospace

- Reactor technology

- Renewable energies (solar thermal energy, wind turbines, ...)

Properties of metal hoses

Due to their material, metal hoses withstand high pressures and offer maximum tightness. Their flexibility makes them extremely tensile and tear-resistant. They are also characterized by corrosion resistance and pressure tightness even under extreme conditions such as aggressive sea water, large fluctuations and extreme temperatures such as B. in space or for the transport of frozen liquid gas.

Braiding of metal hoses

In addition to rubber hoses, metal hoses with single or double braiding are also used to increase the compressive strength. The hose braid is firmly connected to the hose fittings on both sides to absorb the longitudinal force due to internal pressure and, due to its mobility, adapts ideally to the state of movement of the hose. A hose mesh consists of right-handed and left-handed wire bundles that are alternately crossed over and under. It not only prevents the hose from stretching due to internal pressure, but also absorbs external tensile forces and protects the outside of the hose. As a rule, the basic material of the wire mesh is identical to that of the corrugated hose. However, different materials can be selected for corrosion-related or economic considerations.

The braiding also increases the internal pressure resistance of the hoses many times over. The braid adapts flexibly to the movement of the hose, even with a second braid, which is attached to further increase the pressure resistance. The method of fastening the braid to the hose connection fittings depends on the design of the connection fitting and the requirements for the hose. For rough operating conditions, a round wire helix can also be wound up or a protective hose can be pulled over to protect the mesh.

Functional principle of metal braiding

The function of the wire mesh is comparable to the principle of the Nuremberg scissors : by axial pull, the stretch limit is set, at which the wires with the smallest possible angle of intersection lie close to one another and form a hose mesh with the smallest possible diameter and the greatest possible length. When pushed together axially, the crossing angle and diameter increase to the maximum values.

swell

- Koch, Hans-Eberhard: 100 Years of Metallschlauch Pforzheim, 1995

- Witzenmann Group : company archive

- Company history of Witzenmann GmbH by Gregor Mühlthaler

- Reinhard Gropp, Marc Seckner, Bernd Seeger : Flexible metallic cables. In: Die Bibliothek der Technik 382. Verlag moderne industrie, Landsberg Lech 1999, ISBN 978-3-86236-089-5 .

- Carlo Burkhardt, Bert Balmer: Decoupling elements in vehicle technology. In: Die Bibliothek der Technik 237. Süddeutscher Verlag onpact, Munich 2008, ISBN 978-3-937889-73-3 .

- The manual of metal hoses. Witzenmann, Pforzheim 2007.