Ring scales

The ring balance is a measuring device for measuring differential pressure in liquids and gaseous media.

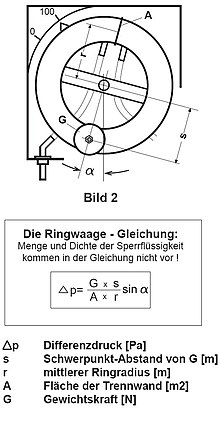

Measuring principle

A rotatably mounted hollow ring, almost half filled with a barrier liquid, is divided at the top by a partition. The chambers above the blocking liquid are connected to the (differential) pressures to be measured via flexible hoses. A pressure difference between the two chambers turns the ring body until an equilibrium of forces is achieved with the counterweight attached below.

Accuracy of the measurement process

The amount and density of the sealing liquid have no influence on the measurement; the calibration is determined exclusively by fixed factors that cannot be changed over the years, because instead of a measuring spring or membrane, the calibration weight determines the measurement. A high long-term accuracy is achieved in this way.

Barrier fluid

The barrier liquid must be very thin, chemically reactive to the parts of the ring balance and the medium to be measured, free of evaporation, as environmentally neutral as possible, heavier than the medium to be measured and, to increase the overload capacity, as heavy as possible. Because of the aforementioned restrictions, almost only oils are used in industrial applications. Mercury is used when differential pressures of liquids are to be measured.

Deployment decisions

Compared to other measuring methods, the high long-term stability and the measurability of very low differential pressures, even at high static pressures, should be emphasized. The disadvantages are the high price, the limited overload protection and the need for vertical installation.

Applications

Since the measuring principle permits very low pressure differences, it can be used in building automation, clean room technology and in furnace or boiler construction. Very small measuring ranges between −25 and 50 Pa are required here.

Measuring transducers (e.g. measuring orifice or venturi nozzle ) are required for flow rate measurements .