Spiral jet mill

The spiral jet mill is the most commonly used form of jet mill . Sizes from the smallest laboratory unit for product samples of just a few grams to production machines for several tons of throughput per hour are used in many branches of industry.

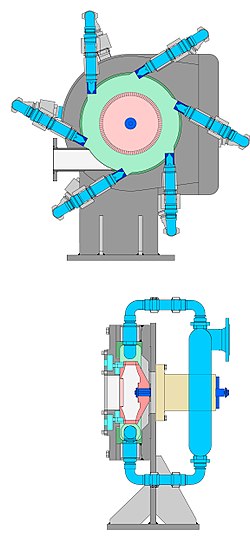

How a conventional spiral jet mill works

The name of this type of jet mill is derived from the basic structure of the machine. Several nozzles are arranged tangentially on the circumference of a round, relatively flat grinding chamber. The flow of the grinding gas entering through this forms a spiral. The product is fed into the grinding chamber via an injector . The material to be ground is captured by the gas jets emerging from the specially designed grinding nozzles, accelerated and crushed by mutual particle collisions. The micronized powder is subjected to a static classification via a dip tube positioned in the center of the grinding chamber. Fine product is discharged from the machine, particles that are too coarse are subjected to renewed grinding stress. The desired grinding fineness is set via the jet loading, i.e. the product throughput. The higher the load, the coarser the grinding result.

A further developed and optimized version of a spiral jet mill was created with the help of a dynamic air classifier : In a dense bed jet mill, the functions “grinding” and “classifying” are separated from each other by an additionally built-in classifier wheel.

How the jet mill works

Here, too, the grinding gas is guided into the grinding chamber in a ring shape via the nozzles and relaxed, with high-speed jets being formed. The introduced grist is caught by the gas jets, accelerated and crushed by particle-particle collisions. The stressed particles are transported by the relaxed grinding gas to the classifier wheel, which is driven by a frequency-controlled motor. The desired target fineness is preset via the speed of the classifier wheel. The fine product particles are removed from the machine via the classifier wheel; Particles that are too coarse are rejected by the classifier wheel and thus get back into the product-laden gas jets for renewed stress. The circular movement of the material that forms in the grinding chamber supports the loading of the jets with particles.

operation area

Due to the compact design and the almost residue-free product grinding, a spiral jet mill is often used in the processing of active pharmaceutical ingredients and excipients. It is also used in the manufacture of cosmetics and the production of pigment preparations.

References

- Netzsch-Condux Mahltechnik, Hanau;