Landing Vehicle Tracked

The Landing Vehicle Tracked ( LVT ; from the further additional designation amphibious tractor came to very familiar name amphtrack , Amtrac or amtrak ) was one of Donald Roebling designed chain-driven amphibious vehicle , mainly from the US Navy and the US Marine Corps also, and in smaller numbers was used by the US Army and the Allies during World War II . The vast majority of these floating tanks were used in the Pacific War . There they could drive over the underwater coral reefs that conventional boats would have stopped. On the European theater of war, these vehicles were rarely used (e.g. Operation Varsity ). The LVTs were converted several times after the end of the Second World War and were also used during the Korean War . Production, which ran from 1942 to 1945, produced a total of 18,621 of these vehicles in a wide variety of variants.

The amtracs were commanded by Major General Roy S. Geiger , Commander of III. Amphibious Corps, during the Battle of Okinawa as "workhorses of the Marine Corps" ( dt. "Workhorses of the Marine Corps"), respectively. Lieutenant General Holland M. Smith formulated the meaning of this vehicle in 1949 as follows:

“The development of the amphibian tractor, or LVT, which began in the middle 1930s provided the solution and was one of the most important modern technical contributions to ships-to-shore operations. Without these landing vehicles our amphibious offensive in the Pacific would have been impossible. "

“The development of the amphibious tractor, or LVT, which began in the mid-1930s [...] was one of the most important modern technical contributions to the conduct of landing operations. Without these landing craft, the amphibious offensive in the Pacific would have been impossible. "

From 1953 they were replaced by the LVT-5 family, which was developed from scratch . The 3rd generation currently in service, based on the Landing Vehicle Tracked, is the AAV7 , which should be replaced by the Expeditionary Fighting Vehicle from 2015 .

Development history

Okeechobee hurricane

The Okeechobee hurricane , which hit the North American mainland on September 16, 1928, is considered to be the trigger for the development of the LVT . He had previously left a trail of devastation in the Caribbean. 600 people died in Guadeloupe and 300 more in Puerto Rico , where he left an additional 200,000 homeless . Among other things, he devastated various boomtowns in the Everglades , which were primarily inhabited by wealthy northerners . One of those affected was John August Roebling II , a noted businessman and philanthropist and grandson of John August Roebling , the designer of New York's Brooklyn Bridge . His winter residence in Lake Placid , 35 miles northwest of Lake Okeechobee, was being remodeled at the time. The workers involved in the renovation were summoned by Roebling to the disaster region to provide help. When they returned a few days later, they could only report on the difficult conditions with which they struggled - ultimately unsuccessfully - because the rescue teams made slow progress with their boats and wheeled vehicles on the muddy and flooded roads. One of the workers remarked to Roebling that a vehicle that could have negotiated roads as well as swamps and deep water passages could have saved many lives.

Interest in the military

John A. Roebling recognized the lucrative and still untapped market for such an ambulance and in 1932 commissioned his then 23-year-old son Donald Roebling to implement his vision, which at the time was building his villa in Clearwater , not far from the lake Okeechobee, was busy. Roebling senior wanted to assume the development and production costs until this vehicle was ready for the market. Donald Roebling and a small staff spent the next two years on his property. In the workshop established there, they built the first prototype called Alligator I and carried out their first swimming attempts in the in-house swimming pool. However, this first draft in appearance and driving performance by no means corresponded to an ambulance. After further work, his Alligator IV was able to meet all expectations.

On October 4, 1937, a two-page article entitled "Roebling's Alligator for Florida Rescues" appeared in the science and business section of Life Magazine . Rear Admiral Edward Kalbfus , Commander of the Battleship Squadron of the US Pacific Fleet , became aware of the richly illustrated report and sent it to the Commandant of the US Marine Corps General Thomas Holcomb in Washington DC The US Marine Corps was investigating Colonel Earl Ellis' studies at the time who had developed the foundations of modern amphibious warfare two decades earlier . Since this vehicle seemed ideal for the implementation of these theories, Holcomb forwarded the article to the equipment department of the Marines in Quantico , whose boss, Brigadier General Frederick Bradman, wrote to Roebling for more information. Other offices reacted more skeptically: The "Committee for Transport and Tanks" announced that the alligator appeared to be "unsuitable for land use" and that its acquisition was not advised. The "Committee on Boats" saw it similarly; only a small number of these vehicles could be used for safety tasks at sea. Both bodies agreed that the insufficient armor and the inadequate chassis would cause problems.

Roebling responded to the Equipment Authority by enclosing a very detailed report of its construction and indicating that the alligator could be viewed at any time. The first tests in different terrain followed, but a funding request to the Chief of Naval Operations was refused. Admiral William Leahy was aware of the valuable properties of the alligator , but the funds required from the landing craft budget were already earmarked for the development of modern landing craft for the Navy. Despite this disappointment, Donald Roebling continued to convert his alligator in order to be able to meet the expectations on the next military visit. In January 1939 he sent photos and drawings to those in charge of the Marine Corps about the progress of the renovation work . Bradman's successor, General EP Moses , was very impressed, and another request for funding was granted; In 1940 Roebling received the first order for a military prototype.

The prototype

On October 18, the Secretary of State for the Navy ordered an "inspection and testing department" under the direction of General Moses to Florida to extensively test the completed Alligator V. Upon completion of the inspection, the vehicle was shipped to Quantico, where it regularly traveled the Potomac River and Chopawamsic Creek . A presentation to journalists, congressmen and senior members of the military from the Army , Marine Corps and Navy was also successful. After further performance reviews, the Marine Corps was able to put its first real amphibious tank into service on November 4, 1940 . In December 1940, was alligator for the first US Marine Brigade to Culebra ordered, where he attended the Fleet Exercise Number 7 (FLEX No. 7) took part, the last fleet exercise of this kind before the entry of the United States into the Second World War . Brigade Commander Holland M. Smith entrusted Captain Victor Krulak (father of the 31st Commander of the US Marine Corps Charles C. Krulak ) and his crew (Sergeant Clarence H. Raper and Corporal Walter L. Gibson) with the task of handling the promising vehicle employ. They did this in great detail in all weather conditions and with the highest waves, so that the alligator successfully completed the practical suitability test.

Start of series production

The troop trials of the alligator were considered a great success, and the Department of the Navy ordered a lot of 200 of these vehicles on February 22, 1941, valued at $ 3,300,000. However, this was not the current version V of the alligator . The navy had two basic requirements: On the one hand, it should be a pure steel construction , as this would offer significantly better protection against enemy fire and coral reefs, and on the other hand, the engine should be replaced by a 146 hp Hercules WXLC-3 .

With this order, Roebling and his team faced the difficult task of converting the alligator so that it met the requirements of the Navy . In order to be able to manufacture the required number of vehicles, a larger factory was required. For this reason, Roebling contacted the nearby Dunedin- based Food Machinery Corporation (FMC) , a manufacturer of insecticide spray pumps. We had been in contact with this company for a number of years, as it had already manufactured several parts of the original "alligators". In the months to come, Roebling's team worked closely with the FMC engineers around James M. Hait to guarantee the new steel construction and the on-time delivery of the 200 copies ordered.

One month late, the first LVT-1 (Landing Vehicle Tracked, Model 1) , the new name, left the FMC's assembly hall in August 1941 . With deliveries significantly delayed and capacity limited in Dunedin, the Department of the Navy funded additional production lines in Lakeland , Riverside and San José . One of Donald Roebling's construction companies received the lucrative construction contract for the production facility in Lakeland.

By the time the first LVTs were completed, the Marine Corps had already established itself in Dunedin. The first Amphibian Tractor School was built on site on May 2nd . Its first commander, Major William W. Davies, was already subordinate to four other officers and 33 Marines at that time. In September production was in full swing, whereupon the 1st Amphibian Tractor Battalion was set up. When the US entered the Second World War, the Department of the Navy ordered more LVTs, so that the battalion grew to six companies : four operational companies with a total of 400 LVT-1s as well as a staff and a maintenance company. On February 16, 1942, this battalion was relocated to the South Seas , together with the 1st US Marine Division, which had emerged from the 1st Marine Brigade , where it opened the Allied offensive in August. At this point the 2nd Amphibian Tractor Battalion was set up in Camp Pendleton , California .

Further development

Originally intended as a pure transporter, this first amtrac soon reached its limits in difficult terrain due to insufficient armor, unreliable suspension and armored tracks . Even so, the Marines recognized the potential of Roebling's invention as an attack vehicle. In the course of the war, heavily armored versions were introduced, as well as variants known as amtanks , which were equipped with guns for combat support . Other decisive innovations for the LVTs were more powerful engines and improved suspension, which was largely carried over from the M3 Stuart .

After the war, prototypes were no longer produced in series.

Scope of production

A total of 18,621 LVTs were produced in a wide variety of variants. In addition to the factories of Food Machinery Corp. in Dunedin and Lakeland, Riverside and San José, other companies were later involved in the production of the LVTs:

- BorgWarner Corporation in Kalamazoo , Michigan

- Ford Motor Company in Detroit , Michigan

- Graham-Paige Motors Corporation in Detroit, Michigan

- St. Louis Car Company in St. Louis , Missouri

variants

Roebling's alligator

When the project started in 1933, Donald Roebling and his development team focused on two main problems that stood in the way of the realization of a versatile and robust amphibious ambulance:

- The weight of the vehicle should be kept low in order to lose as little buoyancy as possible in the water . However, the construction should be robust enough to withstand rough terrain.

- The drive had to be designed in such a way that the "rescue mission" was not endangered. In other words, it should be simple and take up little space.

The developers solved the weight problem with aluminum , a material that was revolutionary at the time. This light material, which appeared suitable for the task, had been in use for almost 40 years, but its use in vehicle construction was a technical novelty and therefore a risk.

The drive on water and on land posed a greater challenge. Roebling wanted to avoid a double drive from the start, i.e. propellers for water travel and a wheel or chain drive for land travel. The requirement to build a simply structured drive that works in both of the intended environments turned out to be a major obstacle. The solution looked Roebling by the drive of the old paddle steamers on the Mississippi from which almost a hundred years previously had revolutionized the shipping industry: on the two crawlers of the chain drive mounted gussets ( paddle plates ; Engl .: "paddle cleats") worked in the water as the Paddle wheels of a paddle steamer and on land like the chains of a conventional tracked vehicle .

After the problem of the mixing drive had been solved, the question arose of how best to process aluminum. The metal tools and machine tools available at the time were unsuitable for the soft aluminum sheets, as were the welding and riveting methods known from steel processing . Over time, it turned out that woodworking machines were more suitable for processing aluminum than those for metal. Roeblings employees did pioneering work in dealing with aluminum.

Alligator I , II and III

The first prototype, the Alligator I , was 7.3 m long and 6.5 t in weight. The driver of the vehicle sat in a simple cab attached to the bow, while the rear sections were kept flat. The 92 hp petrol engine from Chrysler was installed in the rear, where the drive wheel of the track was also located.

With the first test drive of the Alligator I in the spring of 1935, some defects in the design became apparent: the prototype achieved a top speed of 40 km / h on land, but only 3.7 km / h in the water. In addition to the speed, the maneuverability in the water was also poor, which was due, among other things, to the angle plates attached perpendicular to the direction of travel of the chain. The paddle plates and the tracks broke after just a few kilometers on rougher terrain because they were too thin and made of too weak a material.

Although the Alligator I was a disappointment because of its performance, Roebling offered it for sale to the United States Coast Guard and the US Red Cross , but, as expected, the orders failed to materialize.

In April 1936 the Alligator II was completed based on previous experience . The almost 6 t heavy vehicle was powered by an 85 hp V8 engine from a Ford automobile. The diagonally arranged paddle plates and the weaker motor reduced the land speed to 29 km / h, but increased the speed in the water to 8.8 km / h. The twisted sheets also improved stability and control in the water.

The Alligator III tested in September 1936 was 140 kg lighter than its predecessor. Nevertheless, the performance of the 5.8 t vehicle changed less than expected. Roebling suspected the reasons for this in the inefficient suspension and the only slightly improved drive chain, which still broke under high loads.

Alligator IV

In 1937, Roebling and his team completed the Alligator IV , which was more in keeping with expectations than its predecessor.

The most significant change was made to the landing gear suspension. So far, an elastic suspension system has been built into the alligators, as was used in chain-driven armored vehicles . The engineers saw the flow resistance caused by this as a reason for the low speed in the water. Instead, the chain was now laid in a guide channel so that it only ran outside the channel on the guide wheel at the front and the drive wheel at the rear. The guide wheel took over the function of the chain tensioner and could be adjusted by the driver via a hydraulic cylinder , which was provided with coil springs for the purpose of shock absorption . The crawler track was provided with water and dust-tight roller bearings .

The chain material had a yield strength of 36 t. In order to obtain a higher strength, which paddle plates were from Alcoa 24ST by a T-shaped die extruded . The 10 cm wide and high profile bars produced in this way were bent to a radius of 30 cm and mounted on the crawler with four bolts or rivets. Donald Roebling patented this drive principle for tracked vehicles in water using curved angle plates that are mounted diagonally on the chain . A few years later, during the Second World War, he signed over his patent (No.) for patriotic motives for the government of the United States .

The aerodynamic vehicle hull was mainly riveted together from duralumin sheet metal. Only the base plate was screwed in for easier maintenance . The driver's cab attached to the front of the vehicle was 1.9 m wide, 1.7 m long and high and offered space for three people including the driver. The three fixed front windows and the two sliding side windows were made of plexiglass . The rear door closed the cabin watertight to the cargo hold.

The vehicle was controlled with two hand levers that acted on the brakes of the two chains and two pedals for clutch and gas. To control the direction, a chain was braked with one of the levers; synchronous actuation of both levers enabled braking. On the driver's dashboard were the speedometer , compass , thermometer , oil pressure and battery indicators, as well as switches for the ignition , starter , choke and the two headlights .

The cargo and passenger space behind the cabin measured 2.74 × 1.93 × 1 m³ and was designed for a payload of 3.15 t. In the 30 cm high space between the floor of the cargo compartment and the floor plate, there were two 152-liter petrol tanks, as well as the control rods and wiring harnesses for the vehicle control.

The engine room in the rear measured 1.67 × 1.35 × 1.93 m³ and housed the liquid-cooled Mercury V-8 gasoline engine, which generated 95 hp at a speed of 3600 min −1 . The 3-speed manual gearbox with two forward gears and one reverse gear, a bevel gear with spiral gearing ( gear ratio 1: 1), two spur gears with herringbone gearing (gear 7: 1) and the necessary clutches ensured the power transmission to the chain drive wheels. The gearboxes were cast from aluminum for weight reasons . The two drum brakes of the brand Packard 8 were hydraulically operated.

The curb weight of the Alligator IV was 3.95 t, making it 2.5 t lighter than the Alligator I from 1935. This weight saving and the revolutionary drive enabled a top speed of 13.8 km / h on water and 29 km / h on land.

Alligator v

The Alligator V, delivered to the US Marine Corps in October 1940, was an Alligator IV improved at Major Kaluf's suggestion . It is considered the first military variant of the previous alligator family. Instead of the Mercury engine, a 120 hp Lincoln Zephyr with a standard Ford transmission was installed. The total weight was again reduced by 450 kg to 3.4 t. With the same cargo capacity, the same landing gear and the same crawler track, the Alligator V reached a top speed of 47 km / h on land and 16 km / h in water. A contemporary information brochure even said:

“In the open sea, or when landing on a beach through the surf the alligator is more seaworthy than a normal boat of comparable size. It will not sink, even with its 7,000 pound cargo compartment full of water; nor will it capsize in a dive into deep water off a six-foot seawall. "

“Whether on the high seas or when landing due to the heavy surf, the alligator is more seaworthy than a conventional boat of comparable size. It will not sink, even if its 3.2 t cargo compartment is full of water. Nor will it capsize, even if it descends into the water from a six- foot (1.82 m) high embankment. "

LVT-1 alligator

The first LVT-1 was manufactured by Food Machinery Corp. in August 1941 . completed and experienced his baptism of fire in the Battle of Guadalcanal 13 months later . He was in action during the battle for the Solomon Islands and the liberation of the Tarawa and Makin atolls as part of Operation Galvanic . A total of 1225 vehicles of this type had been built by 1943. The main customers were the US Marine Corps with 540 pieces and the US Army with 485 pieces. The remaining 200 LVT-1 went to the Allies under the Loan and Lease Act .

Technical details:

- Chassis : The fuselage, consisting of the three sections of the driver's cab, cargo and engine compartment, was made up of steel plates with thicknesses between 2 mm and 5 mm, which were connected by arc welding . The floor plate running from the rear to the front shock absorber was 4.7 mm thick, the side walls 4 mm and the driver's cab 3 mm.

- Suspension : The stiff chassis construction known from the Alligator IV was retained. In addition to the roller bearings mounted on each track (width: ~ 260 mm, weight: 295 kg), rollers were installed to make the chain guide safer.

- Maneuverability : The tracked vehicle was able to turn on the spot while swimming by reversing the directions of rotation of the two tracks. Due to its heavy weight, this LVT sank about 10 cm into sandy subsoil, with the resulting ground pressure averaging 7.8 psi . Although it had excellent driving characteristics in the water and on the beach, the LVT-1 was unsuitable for long transport trips inland. In addition, there was the extremely time-consuming maintenance that often had to be carried out every day.

LVT-2 Water Buffalo I.

The use of the LVT-1 was a complete success, even though BorgWarner engineers discovered significant deficiencies in Roebling's design as early as October 1941. These were on the one hand the rigid suspension and on the other hand the chain itself.

The US Army also discovered other defects in the vehicle during a test phase running from April 30 to July 20, 1942 at the Aberdeen Proving Ground in the US state of Maryland . Their investigation report mainly criticized the poor driving performance. A propeller-driven watercraft with a streamlined hull (→ Higgin's Boat ) with the same displacement and propulsion power is more than half faster than the LVT. The Army saw reasons for this in the too high flow resistance of the fuselage and in the weak propulsion power.

All of these problems, notwithstanding the improvements, were related to Roebling's Alligator IV , from which the LVT-1 was derived. In addition to Food Machinery Corp. , the US Navy commissioned , which was previously responsible for the production of the amtrac , also includes Borg-Warner Corp. with developing a more powerful successor to the LVT-1. The order also provided for a more heavily armored and armed variant of the LVT. The criteria specified by the navy stipulated a minimum speed of 24 km / h on land and 13 km / h in the water and a maximum weight of 12,250 kg.

BorgWarner refrained from developing a pure transporter and concentrated its efforts on building a combat-ready floating tank (amtank) , while FMC set itself the goal of both. BorgWarner completed its Model A, including the completed test phase, after just six months, creating the world's first modern combat-ready swimming tank with the LVT (A) -1.

FMC worked closely with specialists from the University of California and the California Institute of Technology and at the beginning of 1942 was able to present the first drafts for the armored personnel carrier. With this design, in contrast to the LVT-1, the driver's cab was moved closer to the bow and equipped with two windows made of Plexiglas. The criticized teething problems of the first amtracs have also been significantly revised:

- Suspension: The previously used rigid chassis suspension caused the vehicle to travel slower than other tracked vehicles and the limited off-road capability of the floating tank. The innovation, based on the chassis of the Stuart tank, consisted of eleven chassis shafts mounted on rubber springs on each side with vulcanized rubber . In addition, four cardan joints were inserted between the engine and the suspension in order to decouple the chassis from the engine. Flexible couplings were used to connect the drive gear with the suspension, which allowed a small amount of torso deformation without affecting the driving performance or the power transmission elements. In addition to a smoother and more stable ride, these innovations also made it possible to improve the criticized driving characteristics.

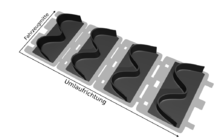

- Chain: The steel link chain was widened to 362 mm and had a pitch of 203 mm. The connecting bolts of the individual links had permanent lubrication and were hermetically sealed so that neither water nor sand could penetrate, which ruled out possible blockages. The basic contact length was 3.2 m. A raised chain guide prevented the chain from being ejected at high speeds and during turning maneuvers on solid ground. Greater propulsion and far better off-road mobility were achieved with 73 W-shaped paddle plates, which were riveted to the crawler with reinforced angle plates. The ground pressure caused by the vehicle weight was 8.6 psi.

The resulting driving characteristics gave him a good certificate. So he had a climbing ability of max. 60% and was able to overcome 91 cm high obstacles and 1.5 m wide trenches. The LVT-2 had a turning radius of 9 m on land and 14.6 m in the water and was able to operate even in up to 30% inclined terrain without losing its balance .

These modifications fulfilled the requirements of the Navy, making the LVT-2 Water Buffalo I the official successor to the LVT-1.

The Water Buffalo I was first used in the Battle of the Gilbert Islands , where it operated for the first and only time together with its predecessor, the LVT-1. Production, which ran from 1942 to 1943, produced a total of 2963 such vehicles. In addition to the factories of the FMC, the production facilities were those of the Graham-Paige Motors Corporation , Borg-Warner Corporation and the St. Louis Car Company . The Marine Corps received 1355, the Army 1408 and the Allies 200 copies ( British designation Buffalo II ).

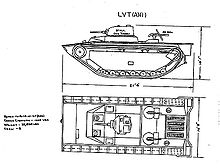

LVT (A) -1

This proposal from Food Machine Corp. was very close to the LVT-2. All that had been added to it was reinforced armor and armament based on multiple machine guns .

The BorgWarner Corp. The Model A conceived was a comprehensive revision of Roebling's Alligator V and the LVT-1: The only thing in common with the LVT-1 was the paddle plates. The rollers of the chains were enlarged in diameter and built into the bottom of the side panel. They were supported by Timken roller bearings with double neoprene and leather seals that ran on chrome-plated shafts. Larger idle rollers and drive gears, which were connected to a fully automatic suspension, allowed a smooth transition of the vehicle drive from water to solid ground. The fuselage consisted mainly of high tensile strength and corrosion-resistant sheet steel, which, in a corrugated form, could withstand the highest loads and, due to the resulting weight reduction, made a positive contribution to the overall work.

The outstanding feature of the Model A was its convertibility: The base vehicle, a 7.7 t tank that can be loaded with up to 2.3 t, could be converted into a 10 t battle tank without any further design effort. The use of the turret used in the M3 Stuart was considered to be the actual innovation, which reduced the production effort and gave the Model A a far higher firepower than the FMC model. In addition, the gyro stabilization of the 37 mm cannon was taken over by the Stuart, which uses the gyro effect to stabilize the barrel in the position specified by the gunner. The gyro stabilizer compensated for the vehicle's movements, which enabled a high level of shooting accuracy to be achieved even at full speed.

The Model A was powered by an eight-cylinder internal combustion engine with an output of 141 hp.

In a closer comparison between the prototypes from BorgWarner and FMC , the Model A turned out to be too weak. The chassis did not produce the desired smooth running and the chain also caused the same problems as with the LVT-1. The driving speeds were almost the same in the water, while the Model A with its 27 km / h could not exceed on land. The transporter variant from Borg-Warner could only transport 2.3 t of freight, the one from FMC up to 7.7 t. On the other hand, Model A scored points with its firepower.

The Navy finally checked the installation of the Model A armament in the FMC-amtrac. The primary weapon of the LVT (A) -1 consisted of a 360 ° rotatable turret, which was armed with a 37 mm cannon and a coaxially mounted machine gun caliber 7.62 mm with a height adjustment range of + 25 ° to −10 °. The tower with a maximum outer diameter of 1.19 m had a speed of rotation of 24 ° per second and a 51 mm thick front armor made of rolled sheet steel. The side walls and the rear wall of the tower were 12.7 mm thick, the cap 6.4 mm. The driver's cab was welded together from 6.4 and 12.7 mm, the side walls from 6.4 mm thick steel plates, while the fuselage floor consisted of a 5 mm thick structural steel plate . The driving characteristics of this variant differed only slightly from those of the LVT-2.

This LVT (A) -1 ("A" for armored ) called floating tank went into production in April 1943 and was first used on Kwajalein . Production, which lasted until 1944, produced 510 units exclusively from the Food Machine Corp. were built. The US Marine Corps received 182 and the US Army 238 such amtanks.

LVT (A) -2

The Battle of Tarawa was a turning point not only for the war strategists, but also for the LVT development. The " 2nd US Marine Division supported the landing". Amphibian Tractor Battalion “recorded only 19 of the 75 operational LVT-1s and 16 of the former 50 LVT-2s at the end of the fight. Personnel losses amounted to 323 fallen , wounded and missing soldiers out of 500, including their commander. Initially, it was assumed that a large number of material losses were due to machine damage, as often occurred with the LVT-1 in particular. Closer investigations did not confirm this thesis, because only four LVT-1 and LVT-2 were lost due to this circumstance, while the remaining amtracs fell victim to artillery fire , land and sea mines or the coral reef . In addition, most LVTs had been in operation for up to 400 hours before the battle - with an average life of 200 hours stated by the manufacturer . The greatest weakness of all amtracs deployed on Tarawa was the lack of armor on the hull and the driver's cab. The two petrol tanks mounted next to the engine exploded after a long period of fire with a heavy machine gun or a piece of shrapnel that had drilled its way through the side walls.

The main focus for the future LVT (A) -2 was the demand for more security through reinforced armor. In contrast to the first armored amphibious vehicle LVT (A) -1, this version had no primary armament in the form of a turret. The body, engine and armament were taken from the LVT-2, so that the (A) -2 looked very similar to the Water Buffalo at first glance. Only the driver's cab, in addition to the additional armor, made the difference. Instead of the Plexiglas windows used, steel doors were built in, which the driver could close in the event of fire. In order not to impair the operational capability, two periscopes that can be rotated by 360 ° were installed.

The armor consisted of 6.4 mm (fuselage, rear of the driver's cab) and 12.7 mm (front) thick armored steel plates, which were additionally welded on or fastened with bolts. This reduced the transport capacity by up to 1.1 t. The first combat missions on New Britain showed, however, that the cargo capacity that was impaired was too small to be used effectively. So it was decided to screw the armor plates onto the fuselage only when needed. This mostly happened at the start of the fight, when the first stormtroopers were brought onto the beach. When the beach was no longer under enemy fire, the self-protection could be removed, increasing the transport capacity to that of the LVT-2. In addition to the periscope, this system of removable armor should also be used in all future amtrac and amtank variants. The addition of a Goodrich Corporation self-sealing fuel tank was another important change that was used in all other LVTs.

With the start of series production of the LVT (A) -2, the SecNav at the time, Frank Knox , created the “Continued Board for the Development of the Landing Vehicle Tracked” on October 30, 1943. This committee of the Bureau of Ships dealt with the supervision of the entire LVT program. As the official complaints commission , it was responsible for the “meaningful” development of these amphibious vehicles.

The amphibious tank produced in 1943 and 1944 was built 450 times, 250 of which were operated by the US Marine Corps and 200 by the US Army. This amtank was manufactured by Food Machinery Corp. and the Ford Motor Company of Detroit, Michigan.

LVT-4 Water Buffalo II

The LVT-4, designed exclusively by the FMC, was an improvement on the LVT-2. In contrast to this, the engine was installed behind the driver's cab, which increased the cargo space and enabled the installation of a stern ramp that was urgently required. The loading ramp, including the necessary reinforcements for the rear fuselage and the manually operated cable winch for opening and closing the ramp, weighed around 1.18 t. This reduced the speed of the LVT-4 compared to its predecessor on solid ground, while the maximum speed in the water remained almost the same. Despite this additional load on the overall structure, which had a negative impact on the increased overall weight, it was possible to transport up to 1.14 t more cargo. The cargo hold floor measuring 2.4 × 3.8 m² (LVT-2: 2.4 × 3.3 m²) made it possible for the first time to transport small vehicles such as the Willys Jeep and even a 105 mm howitzer with a maximally raised muzzle.

In addition, separate armor could be added at the expense of the transport capacity. The payload was reduced by up to 1.36 t when the armored front was retrofitted with 13 mm thick steel plates and both sides with 6.4 mm thick steel plates. The driver's cab had two glass windows and two skylights with periscopes. Their armor was mainly ensured by 13 mm thick armor steel plates.

Production began in December 1943, making the LVT-4 late for the Marshall Island Campaign but ready in time for Operation Forager . By the end of production before the end of the war in 1945, a total of 8,351 LVT-4s left the factory of Food Machinery Corp. , Graham-Paige Motors Corp. and the St. Louis Car Company . The US Army was the main buyer with 6,083 units, followed by the Marine Corps (1765) and the British armed forces (503). The British LVT-4, called Buffalo IV , was equipped with a Polsten 20 mm rapid-fire cannon from Oerlikon instead of the 12.7 mm machine gun and was used primarily at the Battle of the Scheldt Estuary , Operation Plunder and the crossing of the Italian river Po for use. In the Italian theater of war , the LVT-4 carried the code name Fantail to mislead the Germans .

LVT-3 Bushmaster

At the same time as FMC, Borg-Warner Corp. a floating tank with a stern ramp. After the defeat of the Model A , increased efforts were made to develop a more powerful amphibious chain armor similar to that of the competing Food Machine Corp. should be superior. The prototype named in reference to the Model A Model B was completed and tested before the LVT-4.

The Model B was to differ from all of its FMC predecessors in one single detail: the engine. Borg-Warner drove its two 300 mm wide crawler tracks with a 140 mm pitch, each with a motor. The two V8 engines from Cadillac were installed in the side walls of the fuselage and corresponded to the drive arrangement of the M5 tank, the improved successor to the M3 Stuart. This innovation enabled the cargo hold to be extended to 5.1 m, but had to be reduced to a width of 1.9 m. However, since the driver's cab was positioned closer to the bow, the cargo space could be widened to 2.5 m from the last third. Model B thus had the largest cargo hold of all amtracs built up to that point. Despite this advantage, the Bushmaster was only 7.5 m in length, but 3.4 m in width and 3 m in height.

The built-in automatic gearbox was a considerable relief for the driver . This gearbox, also from the M5, was characterized by its reliability as well as the automatic shifting of a lower gear when moving from water to firm sandy ground, where conventional manual transmissions often failed due to operating errors. The suspension corresponded to the principle based on the suspension of the Stuart tanks and meanwhile successfully tested in combat. Propulsion was ensured by 103 paddle plates in the tried and tested W design. Even so, Model B was unable to reach the land speed of its immediate competitor, the LVT-4, due to the 9.5mm armor (fuselage, cab, engine and tank) installed later, increasing the possible cargo capacity by 1.3 t reduced to 4.1 t.

The Continuing Board for the Development of Landing Vehicle, Tracked gave its approval for the production of the now called LVT-3 model in April 1944. The Bushmaster was the first LVT with a rear ramp, which should make loading and, above all, unloading considerably easier. Due to production delays and long training courses for tank crews and mechanics, the LVT-3 was only able to take part in the battles of the Second World War in April 1945 - one year after the start of production. During the Battle of Okinawa this proved itself so much that long after the end of the war it formed the backbone of the US Marine Corps together with the LVT (A) -4 .

A total of 2,964 Bushmasters left the workshops of the Borg-Warner Corporation and the Graham-Paige Motors Corporation between 1943 and 1945 . The Marine Corps was the main user of the LVT-3 with 2,262 copies, while the Army only received two for testing purposes.

LVT (A) -3

The third amtank was very much based on the LVT-4. The main armament should consist of a heavy cannon of larger caliber, which, however, should not be installed in a rotating gun turret. The (A) -3 never got beyond the project stage.

LVT (A) -4

The shape of the LVT (A) -4 was more similar to the LVT (A) -1, but instead of the 37 mm cannon it had the turret and the 75 mm howitzer of the M8 Scott .

There were two reasons for this: on the one hand, the armor of the LVT (A) had proven to be too weak for direct combat on the front line, on the other hand, the 37 mm cannon was well suited for fighting armored vehicles and only slightly fortified positions, but against the heavy Japanese bunkers , their projectiles were almost ineffective. They developed neither the necessary penetrating power nor enough explosive power to damage the bunkers, which were particularly well armored against frontal fire.

However, the Marines had good experience with 75mm howitzers in the battles for Tarawa , Roi-Namur, and Eniwetok . The howitzers had a lower muzzle velocity , but a high explosive effect and hit their target because of their high arcuate trajectory from above, where the bunkers were less armored. In addition, because of the high trajectory, you could shoot over your own troops and also at targets outside the direct line of sight. Only the about 3 km shorter projectile range of the howitzer was to be rated as a disadvantage.

Another difference to its predecessor (A) -1 was the lack of a cannon stabilizer. Due to the parabolic projectile trajectory and the possible height adjustment range of + 40 ° to −20 °, the LVT (A) -4, like the M8 self-propelled gun, was intended for remote support, which made stabilization unnecessary during full speed.

The armor of the LVT (A) -4 was similar to that of the (A) -1. The fuselage was mainly reinforced with 12.7 mm (driver's cab, front), 6.3 mm (fuselage sides and stern) and 5 mm (base plate) thick steel plates. The turret had a maximum outer diameter of 1.38 m and a front armor of 38 mm. The rear and side walls were secured with 25.4 mm thick steel plates, while the turret roof remained open as in the M8 and similar self-propelled artillery howitzers. The original secondary armament from a 12.7 mm machine gun placed on the turret was replaced by three 7.7 mm machine guns.

The LVT (A) -4, which was produced exclusively by FMC in 1944 and 1945 , reached a total of 1890 units. The US Army received 1307 and the US Marine Corps 533 copies, while 50 went to the other Allies under the Loan Act. The LVT (A) -4 experienced its baptism of fire together with the LVT (A) -1 in June 1944 on the Mariana Island of Saipan . Later assignments took place on Tinian , Peleliu , Iwo Jima and Okinawa . The Marine Corps also replaced the howitzer in small numbers with flamethrowers or rocket launchers .

Summary of technical data

Landing Vehicle Tracked

| LVT-1 alligator |

LVT-2 Water Buffalo I. |

LVT-4 Water Buffalo II |

LVT-3 Bushmaster |

|

|---|---|---|---|---|

| crew | Commander , driver and machine gunner (s) | |||

| loading | 24 soldiers or 2 tons | 24 soldiers or 2.7 tons | 30 soldiers or 4.1 t | 30 soldiers or 4.1 t |

| Dimensions | ||||

| Length [mm] | 6553 | 7950 | 7468 | |

| Width (mm] | 2997 | 3251 | 3404 | |

| Height [mm] | 2997 | 2489 | 3023 | |

| Ground clearance [mm] | 482 | 482 | 457 | 482 |

| drive | ||||

| engine | Hercules WXLC-3 | Continental W-670-9A | 2 × Cadillac Series 42 | |

| * Number of cylinders | 6th | 7th | 2 × 8 | |

| * Design | In-line engine | Radial engine | 2 × V8 engine (90º) | |

| * Type of cooling | air | air | water | |

| * Fuel | petrol | |||

| * Power [PS (kW)] (net) | 146 (107.5) | 250 (183.9) at 2400 min -1 | 2 × 110 (80.9) at 3400 min -1 | |

| * Torque [Nm] (net) | ? | 792 at 1800 min -1 | 662 at 1200 min -1 | |

| transmission | Spicer | Manual transmission (5 forward and 1 reverse gear) |

2 × Hydramatic automatic transmission (4 forward and 1 reverse gear) |

|

| steering | Control lever | controllable steering differential | controllable steering differential | |

| Tank capacity [ L ] | 188 | 418 | 530 | 492 |

| Weight | ||||

| Displacement [t] | 7.7 | 11.6 | 10.6 | 12.7 |

| Insert mass [t] | 14.7 | 14th | 16.5 | 17.5 |

| Mileage | ||||

| Top speed land [km / h] |

19.3 | 32.2 | 27.4 | |

| Max. Range land [km] |

241 | |||

| Speed water [km / h] |

9.8 | 12 | 9.7 | |

| Max. Range of water [km] |

96 | 80 | 120 | 120 |

| Armament | ||||

| primary | 2 × Browning M1919 | 1 × Browning M2 3 × Browning M1919 |

2 × Browning M2 2 × Browning M1919 |

1 × Browning M2 2 × Browning M1919 |

Landing Vehicle Tracked (Armored)

| LVT (A) -1 | LVT (A) -2 | LVT (A) -4 | |

|---|---|---|---|

| crew | Commander, driver, gunner , loader and machine gunner (s) | Commander, driver and machine gunner (s) | Commander, driver, gunner, loader and machine gunner (s) |

| loading | 431 kg | 2.25 t | 431 kg |

| Dimensions | |||

| Length [mm] | 7950 | ||

| Width (mm] | 3251 | ||

| Height [mm] | 3073 | 2489 | 3111 |

| Ground clearance [mm] | 457 | ||

| drive | |||

| engine | Continental W-670-9A | ||

| * Number of cylinders | 7th | ||

| * Design | Radial engine | ||

| * Type of cooling | air | ||

| * Fuel | petrol | ||

| * Power [PS (kW)] (net) | 250 (183.9) at 2400 min -1 | ||

| * Torque [Nm] ; (net) | 792 at 1800 | ||

| transmission | Manual transmission (5 forward and 1 reverse gear) |

||

| steering | controllable steering differential | ||

| Tank capacity [L] | 401 | 418 | 401 |

| Weight | |||

| Displacement [t] | 11.4 | 12.5 | 17.2 |

| Insert mass [t] | 14.9 | 18.1 | |

| Mileage | |||

| Top speed land [km / h] |

40.2 | 32.2 | 40.2 |

| Max. Range land [km] |

201 | 241 | 201 |

| Speed water [km / h] |

11.2 | 12 | 11.2 |

| Max. Range of water [km] |

120 | 80 | 120 |

| Armament | |||

| primary | 37 mm M6 cannon 1 × Browning M1919 MG |

1 × Browning M2 3 × Browning M1919 |

75 mm howitzer M8 |

| secondary | 2 × Browning M1919 | - | 3 × Browning M1919 MG |

Post-war development

After the end of the Second World War, the production and development of the Landing Vehicle Tracked was discontinued. The US armed forces unified their amtrac and amtank fleets so that only the LVT-3 Bushmaster and the LVT (A) -4, which has been upgraded to LVT (A) -5, formed the backbone of the US Marine Corps' amphibious landing force.

All other versions were sold or given away to the armed forces of friendly states as part of the reconstruction aid and then sometimes served for decades with the armed forces of Great Britain (also as a replacement for Terrapin Mk I ), Spain , Brazil , the Netherlands and France . France still used its LVT-4 and (A) -4 in the Indochina War and during the Suez Crisis of 1956. Until the commissioning of the LVT-5 family in 1953, which was the first redesign of the LVT family, the LVT-3C remained next to the (A) -5 in the arsenals of the US Marine Corps.

LVT-3C

From 1949 about 1200 LVT-3s of the Marine Corps at the Long Beach Naval Shipyard were upgraded to the new LVT-3C standard ("C" stands for covered ; German: "roofed"). A hinged aluminum “roof” with hatches was drawn in over the cargo hold, which offered protection from breaking waves and shrapnel . The armament consisted of Browning M1919 machine guns , which were installed in an armored turret that could be rotated through 360 ° and next to the driver. In addition, the armor was reinforced. To increase the buoyancy in the water, the bow had to be widened, as these modifications had a negative impact with an additional 2.7 t. The LVT-3C was successfully used in the Korean War, where it was mainly used on land, as the amphibious landing operations were limited to the landing at Incheon . In contrast to its predecessor, the majority of the LVT-3C fleet did not suffer any major engine damage, as the machine maintenance could be carried out within the prescribed intervals.

LVT (A) -5

The only difference to its predecessor was the installation of a gyro stabilization for the gun, which allowed a high degree of shooting accuracy during water and land travel. The Food Machinery Corp. built only 292 pieces of this tank from April 1945, but they were no longer used in the Pacific War. After the Japanese surrender, the LVT (A) -4 returning from the theater of war were converted to this new standard or passed on to other countries.

Subsequent generations

With the foreseeable end of the Korean War, the US Marine Corps was looking for a complete replacement of its LVT fleet, which had been unified to the LVT-3C and LVT (A) -5 since the end of World War II. The development of the LVT-5 generation began as early as 1951 . In addition to the previously known types of use as a troop transport or fire support vehicle , special command, pioneer and air defense models were also put into service from 1956 . From this family 1124 copies were built, which were mainly used during the Vietnam War .

With the end of the Vietnam War, the second was replaced by a newer generation of amphibious landing vehicles. The LVT-7 was renamed the Assault Amphibious Vehicle in 1987 to meet the changed requirements. After several modernization programs, it is still in service with the US Marine Corps and is mainly used by the amphibious assault ships of the Tarawa and Wasp- class . Due to numerous losses in the Iraq war , the Expeditionary Fighting Vehicle was chosen as its successor . Vehicles of this type should be officially put into service from 2015. In early January 2011, the US Department of Defense announced that it would cancel the EFV project due to cost reasons. In return, the existing AAV7 vehicles are to be modernized and a cheaper alternative is to be purchased at a time that has not yet been determined.

Despite all the changes in the range of applications, the naming and on the Landing Vehicle Tracked itself, these vehicles are still known today as amtrac .

See also

literature

- Steven Zaloga , Terry Hadler, Michael Badrocke: Amtracs. US Amphibious Assault Vehicles . Osprey Publishing, Oxford 1999. ISBN 1-85532-850-X .

- Steven Zaloga: Armor of the Pacific War . Osprey Publishing, Oxford 1999. ISBN 0-85045-523-5 .

Web links

- Genre TSLA (English)

- Pictures of Amtracs during the Battle of Tarawa ( Memento from December 16, 2007 in the Internet Archive )

- LVTs according to ibiblio.org (English)

- History of the LVT (English)

- Find out more about the LVT-1 (english)

Individual evidence

- ↑ Richard W. Roan (Retired Major, USMC): Roebling's Amphibian, The Origin Of The Assault Amphibian . Quantico 1987 ( globalsecurity.org ).

- ↑ a b American Society Of Mechanical Engineers [ASME] (Ed.): The Alligator Amphibian, A Historic Mechanical Engineering Landmark . May 21, 1997, p. 10 ( files.asme.org ( Memento of March 16, 2007 in the Internet Archive ) [PDF; 849 kB ; accessed on December 27, 2006]). The Alligator Amphibian, A Historic Mechanical Engineering Landmark ( Memento of the original from March 16, 2007 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Richard W. Roan (Retired Major, USMC): Roebling's Amphibian, The Origin Of The Assault Amphibian . Quantico 1987, Chapter 3 - The Marine Corps' Amphibian ( globalsecurity.org ).

- ↑ a b c d e f g Landing Vehicle Tracked. (No longer available online.) In: wwiivehicles.com. Archived from the original on July 6, 2015 ; Retrieved November 28, 2006 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ Alfred Dunlop Bailey (Retired Major, USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 43 ( ibiblio.org ).

- ^ Alfred Dunlop Bailey (Retired Major, USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 59-61 ( ibiblio.org ).

- ^ Alfred Dunlop Bailey (Retired Major, USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 95 f . ( ibiblio.org ).

- ^ Richard Doherty: Victory in Italy: 15th Army Group's Final Campaign 1945. Pen & Sword Military, Barnsley 2014 ISBN 978-1-78346-298-8 p. 43

- ↑ LVT-3. In: www.globalsecurity.org. Retrieved December 3, 2006 .

- ^ Alfred Dunlop Bailey (Retired Major, USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 161-164 ( ibiblio.org ).

- ↑ LVT-1. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ↑ LVT-2. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ↑ LVT-4. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ↑ LVT-3. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ^ A b c d Alfred Dunlop Bailey (Major ret., USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 62 ( ibiblio.org ).

- ^ A b Alfred Dunlop Bailey (Major ret., USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 159 ( ibiblio.org ).

- ^ Alfred Dunlop Bailey (Retired Major, USMC): Alligators, Buffaloes and Bushmasters - The History of the development of the LVT through World War II . Washington DC 1976, p. 227 ( ibiblio.org ).

- ↑ LVT (A) -1. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ↑ LVT (A) -2. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ^ LVT (A) -4. In: American Fighting Vehicle Database. Retrieved April 1, 2007 .

- ^ The USMC's Expeditionary Fighting Vehicle. In: defenseindustrydaily.com. Retrieved May 15, 2011 .