Tray column

In process engineering, a tray column is a system for the thermal separation of mixtures of substances . The tray column is the special form of a rectification column .

construction

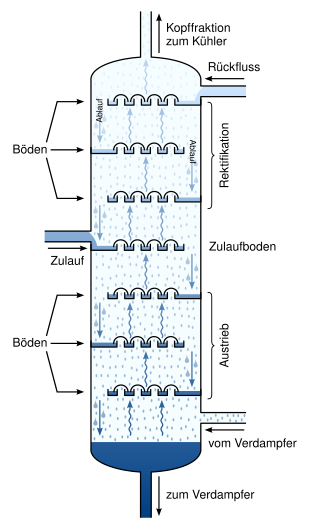

Tray columns contain horizontal internals, so-called trays, at regular intervals. Bottoms consist of circular plates with several openings for the gas flow - so-called bells, slots or valves. The trays are installed horizontally in the column at regular vertical intervals of 0.3 to 1.0 m.

Operating mode

There are two phases within a tray column, one phase being liquid and one being gaseous. In the column, the gas flows upwards from below through openings in the base plates in the column, whereas the liquid flows downwards in countercurrent. The floors catch the flowing liquid material flow. On each individual tray, the gas penetrates from the openings in the base plate in the form of fine bubbles into the liquid from bottom to top, creating a two- phase layer with a large phase interface. On a single floor, the two phases move in a cross-current. A highly turbulent bubbling layer is created, which turns into a spray layer at the top. Above the spray layer there is a calming zone that is supposed to prevent the vapor from dragging drops of liquid with it. The heat and material exchange between vapor and liquid takes place in the bubble and spray layer on the floors. On each of these soils, a new temperature-dependent equilibrium is established between the liquid and gas phases. Ideally, one tray corresponds to a theoretical separation stage. The phases then separate again and the gas flows up to the floor above. In the calming zone, the two phases flow past each other without significant contact. The liquid collects at the bottom of the column and the gas at the top. The liquid runs through the outlet to the evaporator and is fed back into the column. A small part of the now pure gas is drawn off and collected, while the majority is fed back into the top of the column as so-called reflux.

Floors are used with large material flows, with changing loads and when there is a risk of contamination. The pressure loss per theoretical tray is relatively high.

literature

- Daniel S. Christen: Practical knowledge of chemical process engineering: Manual for chemists and process engineers . 2nd edited and supplemented edition Springer, Berlin 2010, ISBN 978-3-540-88975-5 .

- Johann Stichlmair: Basics of the dimensioning of the gas / liquid contact apparatus, tray column . 1st edition Verlag Chemie, Weinheim 1978, ISBN 3-527-25811-6 .

Individual evidence

- ^ A b c Daniel S. Christen: Practical knowledge of chemical process engineering: Handbook for chemists and process engineers . 2nd edited and supplemented edition Springer, Berlin 2010, ISBN 978-3-540-88975-5 , p. 138 .

- ^ A b c Daniel S. Christen: Practical knowledge of chemical process engineering: Handbook for chemists and process engineers . 2nd edited and supplemented edition Springer, Berlin 2010, ISBN 978-3-540-88975-5 , p. 437-438 .

- ↑ Johann Stichlmair: Fundamentals of the dimensioning of the gas / liquid contact apparatus, bottom column . 1st edition Verlag Chemie, Weinheim 1978, ISBN 3-527-25811-6 , pp. 6-7 .