CLP Fleck Sons

CLP Fleck Sons in Berlin-Reinickendorf was a machine factory founded in 1859 that specialized exclusively in the manufacture of sawing and woodworking machines.

Products

Around 1908, in addition to carpentry machines with patented ball bearings, the company produced all kinds of sawing and woodworking machines, veneer saws, slicing and peeling machines for up to 10 mm thick, guaranteed break-proof veneers. As a unique selling point, the company produced patent drying systems, hydraulic veneer presses and saw frames in solid design and with the highest performance.

Horizontal gate

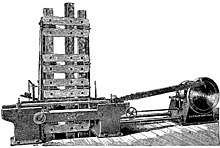

The design of the horizontal creel manufactured by CLP Fleck Söhne in Berlin-Reinickendorf around 1901 met the conditions for good operation:

- The vertical gate stands stood on a common base plate to enable precise installation.

- The horizontal plate with the guides of the saw frame (saw support), which could be adjusted up and down on these frame stands, was built strong and did not allow any vibrations during operation.

- The saw blade had a long stroke so that the chips could be easily ejected from the cut on both sides.

- The saw frame was made of wood, light and yet sturdy in order to enable a high sawing speed.

- At that time, the best guide for the saw frame was considered to be one on which the screwed-on pockwood jaws slid in cast-iron prismatic guide rails attached to the horizontal plate (saw support).

Clamping two saw blades into the multi-patented double saw tang was not recommended in order to increase the frame performance, as the required stronger tension of the two saws also requires a stronger and therefore heavier saw frame, which must not be moved as quickly as a light frame only one saw. At the lower cutting speed, however, the cut surface became somewhat uneven.

The increase in performance would only have been small if a second saw blade had been clamped in due to the reduced number of cuts. In general, the use of two saw blades was only possible when cutting narrow boards up to 30 cm wide, but not for cutting thick ones, as the adjustment of the blade guides above the saws for the lower of the two blades was extremely imperfect.

Technical innovations

Around 1908, the company introduced a valuable innovation with the arrangement of ball bearings on the work spindles, drive shafts and loose disks of the woodworking machines. After many years of trials and experience, she introduced ball bearings to almost all of the machines she built and thus achieved the following advantages, among others:

- The power consumption of machines with ball bearings is considerably lower than that of machines with ring lubrication bearings. After tests, surface planing machines with a planing width of 600 mm saved about 0.45 HP with the ball bearings and 3 to 5 HP with large four-sided planing and mouldering machines.

- The ball bearings only needed to be lubricated every six weeks. The oil consumption was therefore less than a liter a year.

Veneer saws

The veneer saws manufactured by Fleck Söhne, Berlin-Reinickendorf were used both for sawing fine wood into veneer and for cutting planks into thin boards with minimal loss of cut. Its light, easily replaceable saw frame, made entirely of steel and iron, ran in guides with automatic lubricating devices.

Due to the low thickness of the saw, a guide knife was provided that was used when sawing veneer, while so-called grid knives were used to guide the saw with larger dimensions. The wood to be sawed was either held directly on the vertical slide with clamping claws or, better still, glued to a special frame. The exact setting of the veneer thickness was effected by a graduated disk. The feed was variable and could also be switched off immediately.

When the slide was lowered, a differential brake came into operation after the feed wheel was triggered, by means of which the slide can be easily held at any altitude. The balance of the sled including the stretched wood was done by counterweights, which were housed in a box in the smaller machines and which were stacked on top of each other in the larger machines and were connected to the sled by chains running over rollers.

The crank block, which was made of a hollow cast body, was connected to the underframe of the machine by anchors.

Factory building

The machine factory was founded in 1859 on Chausseestrasse, but in 1892 it moved to an industrial plant, presumably designed by the architect Wittmann and functionally structured in the depths of the narrow property, at Flottenstrasse 50-53.

The two-story management building stood on the street. Behind it stood the mechanics and assembly halls, which were connected to one another by a forge and boiler house, and two outbuildings along the western property line. To the west of the northern workshop, a shipping hall was built in 1914 in iron framework with brick infill.

The uniform choice of materials with yellow brick facing on the façade and the use of decorative gables and shapes testify to uniform planning. The facades of the management building and the front sides of the mechanics and assembly hall are clad with gables in the Renaissance style, but the long sides of the halls and the facades of the other buildings are purpose-built brick.

In the interior of the three-aisled factory halls, an engineering-grade functionality determines the overall picture. Two rows of iron truss supports carry a crane runway. The family company has not used the site since 1980 and the company premises are now used differently. From 1998 to 2004, however, the CLP Fleck Söhne Beteiligungsgesellschaft mbH continued to exist in Ibbenbüren .

Patents

- Forwards and backwards cutting veneer knife machine. DE501888C, July 5, 1930.

- Switching mechanism for saw frame. DE509586C, October 20, 1930.

- Automatic veneer tape shortener. DE590788C, July 19, 1931.

- Sizing machine for crate boards. DE550007C, September 19, 1931.

- Overvoltage protection for rotary peeling machines. DE532044C, August 20, 1931.

- Automatic veneer tape shortener. DE542716C, January 30, 1932.

- Machine for the production of lateral surfaces for wooden buckets. DE615281C, September 5, 1933.

- Device for clamping the pressure beam on veneer knife machines. DE595334C, April 12, 1934.

- Veneer knife machine. DE658731C, November 26, 1935.

- Veneer joining machine. DE669097C, May 11, 1937.

- Arrangement for controlling the scissors on veneer splicing machines. DE1631237U, July 28, 1951.

- Grinding machine. DE1651006U, September 25, 1952.

- Fast planer. DE1686169U, July 20, 1954.

- Joining scissors. DE1798972U, July 16, 1959.

- Veneer joining machine. DE1823507U, August 18, 1960.

- Discharge device for veneer joining machines. DE1834234U, April 26, 1961.

- Feeding device for veneer joining machines. DE1834235U, April 26, 1961.

- Veneer knife machine, DE1845168U, October 27, 1961.

- Device for transporting plates or the like. DE1861476U, August 14, 1962.

- Machine for debarking tree trunks. DE1861247U, August 14, 1962.

Web links

- Protective devices on a band saw, ca.1903.

- J. Gillrath: Machines for veneer and plywood mills. In: Woodworking machines and woodworking at home and abroad. Springer, Berlin, Heidelberg, 1929. ISBN 978-3-662-32069-3 .

- Fleck's gate for sawing short pieces of wood. Polytechnisches Journal, 1882, Volume 243 (pp. 106-108).

- Excenter angel from CLP Fleck Sons in Berlin-Reinickendorf.

Individual evidence

- ^ Main catalog of the machine factory CLP Fleck Sons. Berlin-Reinickendorf. Sole specialty since 1859: sawing and woodworking machines. Berlin, no publisher information, no year.

- ^ Advertisement in Der Deutsche Tischlermeister around 1908

- ^ Georg Braune: Plant, establishment and operation of the sawmills. 1901.

- ^ Julius Alexander and Gottfried Bode: Workshops. Springer-Verlag, 1908 and 2013. p. 184.

- ^ Otto Lueger: Lexicon of the entire technology. Published by Otto Lueger, 2nd edition, 1904–1920.

- ↑ CLP Fleck Sons plant.

- ↑ CLP Fleck Sons Beteiligungsgesellschaft mbH, Ibbenbüren.