Cooling rod

Refrigerated container ships for the transport of porthole refrigerated containers require ship-mounted cargo refrigeration systems and cooling rods to supply the refrigerated containers with cold air. Since this type of ship requires considerably higher investments than refrigerated container ships for integral containers , it has not been built since 1995.

First generation refrigerated container ships with horizontal cooling rods

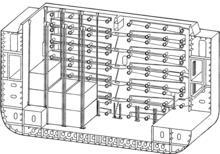

Porthole refrigerated containers (porthole containers), also known as insulated or con-air containers, which are cooled by ship-mounted refrigeration systems, require cooling rods in the hold. The first generation of reefer container ships such as B. the Encounter Bay class (1969) were equipped with horizontally arranged cooling rods.

Second generation reefer container ships with vertical cooling rods

The following two generations such as B. the container ships of the Hamburg Express class of Hapag or the Cap class of Hamburg Süd received vertical cooling rods. This arrangement was very convenient for on-board operations and enabled a clear division of the containers and temperatures. This resulted in safety even with smaller loads and reduced the possibility of errors.

Technical description of the cooling rods

All cooling rods are insulated and divided into a supply and exhaust air duct each. Each cooling rod has a heat exchanger. This is either an air cooler (brine-air) in the indirect system or an evaporator (refrigerant-air) in the direct system. The air circulation in the cooling rod and thus the heat dissipation in the connected porthole containers is done by one, rarely two, circulation fan . If there is only one circulating fan, the electric drive motor is designed to be pole-changing , then two speeds and thus different air volume flows are possible.

The porthole refrigerated containers were cooled through two openings at the front, hence the name porthole container. The cold air from the cooling rod flows through the lower opening into the container, the heated air exits again through the upper opening. The heat dissipated from the containers with the cold air system is ultimately dissipated as condensation heat of the refrigerant with the fresh cooling water to the seawater. With integral containers, the condensation heat is dissipated to the ambient air.

One temperature can be set per cooling rod. Depending on the size of the ship and the height of the hold, five to nine porthole containers ( Transvaal ) can be connected to each vertical cooling rod . The porthole containers are almost only transported below deck on the CON-AIR refrigerated container ships; here they are connected to the cooling rods via special couplings. Refrigerated containers on deck received clip-on refrigeration units that were connected to refrigerated container sockets.

Cooling rods in the ports

The shipping companies in the north-south services with a high proportion of refrigerated cargo, together with the most important ports, had also set up appropriate logistics from 1966/67, ie there were also many refrigeration rods in the container terminals of these ports. In Germany it was the ports of Hamburg and Bremerhaven that were equipped with this infrastructure. In the meantime the porthole technology has been converted to integral containers.

literature

- H. Linde: For transporting refrigerated cargo in containers on board ships. Hansa No. 24/1971

- K.-H. High-rise: technical developments for reefer container ships. Ship & Harbor No. 10/1993