Light trap

Light catching is a term used in printing technology and describes the phenomenon that a material printed using the halftone printing process absorbs more light than the size of the printed area. If 50% of the surface of a white material is printed with black halftone dots , one could expect a reflection of 50%. However, the actual value is lower. The grid area appears darker or more strongly colored in four-color printing. The additional contribution to the tonal value can amount to over 10% and is therefore not negligible. As part of standardization, it is taken into account for offset printing in standards (process standard offset). The light trap is not tied to a specific printing process. Glazing (transparent) layers of paint with grids and printing materials are required, into which the light can penetrate.

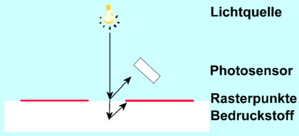

Mode of action

If light falls on grid points, part of it is absorbed (= caught). If light falls between the grid points on unprinted material (substrate), it partially penetrates into the material. The light that has penetrated the paper is scattered back on fibers and filler crystals. The scattered light that goes back to the surface falls partially from the back through grid points and is absorbed there depending on the wavelength. A grid section therefore absorbs more light than corresponds to its color-covered area: the optically effective area coverage, the tonal value , determined by densitometry measurement technology , is greater than the geometric area coverage. It depends on the grid and the substrate. Transparent substrates and those into which light cannot penetrate (e.g. sheet metal) do not trap light. The more light that can penetrate a paper, the greater the proportion of light trapping that can be detected when measuring the tone value. A natural paper (uncoated paper) thus makes a greater contribution to light trapping than a coated one . Two competitions play out at the edges of the grid points: Part of the light falls into the paper next to a grid point, is scattered there and comes out through the grid point. The color portion of the reflected light is increased by half the amount (one passage through color). On the opposite side of the dot, a ray of light falls through the dot into the paper, is scattered away from the dot and emerges at the unprinted area, consequently only bringing half the color component (only one passage through the color). The first beam enters the paper without being weakened, the second already weakened by absorption in the raster point. The first will penetrate deeper and allow more scattered light than the second. All in all, there is an increased color effect.

Influence of the grid construction

Since the light capture takes place on the edge lines of the grid points, it is stronger with fine grids than with coarse grids. Fissured grid points bring more light than compact ones. This is of great importance in modern raster technology . Because of this effect, the tonal values in prepress must be designed accordingly, depending on the screening process, so that a screen area in an autotypical image does not become too dark when transferred to a fine FM screen . This has further consequences because the same color effect (optical density), once produced with more printing ink and once with less printing ink, produces different color tones. The print with a higher proportion of light catching is cleaner (less blacked out). The effect is so clear that it can lead to noticeably improved print quality even in newspaper printing.

Individual evidence

- ↑ Helmut Kipphan: Handbuch der Printmedien . 1st edition. Springer-Verlag, Berlin Heidelberg 2000, ISBN 3-540-66941-8 , pp. 106 .

- ↑ FOGRA research report 65.010 Color space expansion in newspaper printing through the use of non-periodic screens H. Pertler 06/2002