Coated paper

Coated paper - also known as art or picture printing paper - is a paper on which the surface is refined with a binding agent ("line"). So-called coating color is used as the material for applying the binding agent, the main component of which can be chalk , kaolin , casein or plastic dispersion . This gives the paper a more closed, smoother and more stable surface, which results in a high level of detail reproduction and better quality when printing .

Paper without a binder is called uncoated paper or natural paper . However, the surface of natural paper can be surface-treated and may contain up to 5 g / m² of pigments .

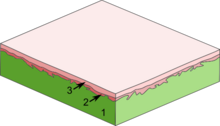

Structure and variants

The line can be matt or glossy, one or both sides. By means of doctor blade or air knife or by means of a scraper ( English blade ) can in papers, are where high demands on a smooth and glossy surface (z. B. for image volumes), up to three times bar are applied. Basically, all papers are initially matt after the coating. To get a glossy paper, it is also run through the calender , which smooths the paper by applying pressure from two rollers.

A distinction is made between:

- matt coated papers,

- semi-matt coated papers,

- shiny papers and

- Cast-coated papers with a mirror-like surface that were manufactured using the cast-coating process. After the actual coating has been transferred, the coating color is dried in contact with a hot chrome cylinder. As a result, the high gloss of these products is practically the mirror image of this chrome cylinder.

properties

The objectives of the mineral coating are:

- Improvement of the printability

- Achieving a smoother, more homogeneous surface

- wettability adapted to the printing process

- optimal ink absorption / ink retention

- Better overall opacity

- Partial gloss

- Better visual appearance (higher quality paper)

- Increase in basis weight and density

- special properties e.g. B. fat or gas (aroma) tightness

history

Coated papers were already known in ancient China and Arabia . Here we used starch and minerals , which were painted by hand on the paper surface (Handpapiermacherei). The artisanal colored paper-making in Europe occasionally practiced the coating method for the production of simple colored paper, along with other techniques. Were machined coating color for the first time in 1866 in Dresden applied with a roller on paper and then rubbed with a brush and smoothed. Further development in Germany was driven, for example, by the colored paper mill in Aschaffenburg and by countless other paper mills in Europe. The Scheufelen paper factory, founded in 1855, produced the first art paper coated with satin white and chalk in Europe in 1892 .

Since then, the coating technique has been further refined - also in the course of the requirements for the printability of papers - both with regard to the composition of coating colors and the mechanical equipment. The coat application (coat weight) today is between 5 and 20 g / m², depending on the purpose of the paper, with one or both sides, single or double (sometimes triple) being coated depending on the use. In connection with a subsequent calendering , certain degrees of gloss of the paper surface can be set, e.g. B. matt , semi-matt , glossy or high-gloss . The technical advancement of the online coating machines led to machines with a width of over 10 meters and a running speed of over 3000 m / min.

Web links

- Lexicon printing company - coated paper. Printing company cyberhafen.de, April 22, 2003, archived from the original on July 1, 2006 ; Retrieved October 26, 2016 .

Individual evidence

- ↑ Natural paper in the paper dictionary on papyrus.com

- ↑ Lexicon of the types of paper. In: Jürgen Blechschmidt (Ed.): Taschenbuch der Papiertechnik , Fachbuchverlag Leipzig in Carl Hanser Verlag, 2nd, updated edition 2013, pp. 39–51.

- ↑ Joseph Needham : Science and Civilization in China: Vol. 5 Chemistry and chemical technology , Cambridge University Press, 1985, ISBN 0-521-08690-6 , pp. 73 f.