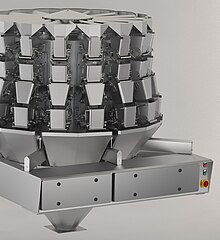

Multihead weigher

Multihead weighers (also combination weighers or partial quantity weighers , eng. Multihead weighers or combination weighers ) are used in the food industry to fill containers (e.g. bags, boxes, cups, cans or glasses). The ability to accurately maintain a set target weight at high speed plays a critical role in the automation of packaging processes.

description

function

With a circular multihead weigher , the product is fed in the middle above the weighing system (e.g. on a distribution plate). From there, the product is conveyed radially outwards to the circularly arranged storage containers and then into the weighing containers below. From several partial quantities, a computer determines the combination that comes closest to the target weight and initiates the simultaneous pouring out. The emptied storage and weighing containers are then immediately filled again. Nowadays, in addition to the circular models, there are also multihead weighers with an arrangement that makes it easier for an operator to intervene manually in the event of product clumping and when handling sticky products. Techniques used to move the product from the distributor plate to the weigh bin include gravity combined with vibrations, coreless screws, and conveyor belts.

history

After the Second World War , increased demands on the quality of products, legal regulations and reduced production times resulted in a change to more precise, faster, simpler, more reliable and more efficient weighing technologies. The multihead weigher was invented in 1972 to weigh green peppers, which had previously been packed manually, faster and more accurately. The new technology was quickly adopted into a number of other foods, including vegetables and snacks. The process “... revolutionized the principles of industrial weighing. For packaged products, maximum weight deviations of ± 1 g can be maintained, regardless of the size and nature of the packaged goods "

In the seventies and eighties, the use of multihead weighers spread particularly quickly in product categories that involved easily movable individual products - such as cherry tomatoes or potato chips. In the meantime, however, thanks to the technical advancement of the multihead weigher, increasingly sticky and 'unruly' products could be automatically weighed - including fresh meat, poultry, cheese preparations and salads. At the same time, automated weighing of small-sized products, such as coffee granules or black tea, became possible. In addition, multihead weighers were designed to handle sensitive products, e.g. B. cookies, or elongated products such as pretzel sticks to weigh.

For some time now, multihead weighers have also been used to quickly create product mixtures with constant mixing ratios. For this purpose, the scales are divided vertically and each provided with individual product inlets and outlets. Each division works like an independent scale with a specific target weight, whereby the individual products are brought together in the specified mixing ratio at the lower end of the scale and discarded together.

Single receipts

- ^ Force Measurement Panel (2010). A Guide to Dynamic Weighing for Industry. London: The Institute of Measurement and Control. 22-28. (Downloadable free from www.npl.co.uk/instmc-wfmp)

- ↑ Kageyama, T. (2006). Development Trend of Recent Weighing Machines. Japanese Packaging Institute Journal. 44 (11): 863-867.

- ^ Ho, E. (2009). Form / Fill / Seal, Vertical. In: Yam, KL Encyclopedia of Packaging Technology. 3rd ed. New Jersey: Wiley & Sons. 546.