Network theory

The network theory is a design method for fiber-plastic composites . It was developed in the early days of fiber composite processing. In network theory, the matrix is neglected and the fibers are assumed to be a self-supporting network. As a result, the network theory is able to determine the layer stresses by means of simple equilibria of forces. Since only equilibria of forces have to be established, no elastic quantities are necessary in network theory.

The network theory is limited to membrane stress states. It can handle laminates with up to four fiber directions. Components designed using network theory are optimal in terms of weight and rigidity. This follows from the criteria of Michel and Maxwell .

Assumptions and Definitions

- Only plane stresses (2-axial) can be treated.

- The matrix is neglected.

- There are only tensions parallel to the fiber.

- The layers are built up from ideal UD layers .

- The layer angles are specified in relation to the coordinate system of the principal normal stresses.

application

advantages

The network theory is used for components that are exposed to long-term or high temperatures. Since the matrix creeps or relaxes under these conditions, the loads are redistributed in the fibers. The contact area of the matrix is reduced, so that the assumption of the network theory is fulfilled better and better. Components that are designed according to network theory are largely stable even if the matrix fails. Therefore, the network theory is particularly used in pressure vessel and pipeline construction.

Components that are subject to vibrations and are designed using network theory have particularly high vibration strengths. The reason is the low stress on the matrix and the fiber-matrix adhesive surfaces.

The network theory serves as a design method to find laminates that are optimal for lightweight construction. Such a design can then be refined using the classical laminate theory . In general, the results according to classical laminate theory and network theory agree better, the greater the ratio of longitudinal to transverse modulus of the unidirectional layer .

disadvantage

Network theory is a conservative design method. The utilization of the components is less than when designing with the classic laminate theory . Laminates based on network theory fail suddenly. Since they are statically determined, they cannot transfer loads. The failure of one layer leads to the total failure of the laminate.

In some cases, the result of the design is only optimal for a certain stress state. This must be known before the design. If the load changes in amount and direction, the laminate is theoretically no longer stable. However, since the matrix transfers loads in reality, the laminates can still be used. The design of robust laminates is possible.

The network theory is not applicable to components subject to bending. It does not provide any global elastic constants. Furthermore, no arbitrary fiber structures can be calculated. The network theory only provides global layer stresses and not the stress in the fiber and matrix.

Design rules

The design rules are based on the principal normal stresses. In the main normal stress system, only normal stresses and no shear stresses act. There are also structures that violate the following rules. However, these structures can only be produced with increased fiber expenditure.

Rule 1

The same tensile stress must prevail in all tensile stressed layers, the same compressive stress in all compressive stressed layers.

This rule reflects the principle of uniform utilization.

Rule 2

An optimal fiber arrangement is always achieved when the fibers lie in the main normal stress directions.

A cross bond is therefore always an optimal laminate, as the fibers cross at 90 °. Only its layer thicknesses still need to be adjusted.

Rule 3

The principal normal stresses have the same sign . The fiber angles must be chosen so that all layer forces have the same sign.

Rule 4

The principal normal stresses have different signs. There is only one optimal fiber arrangement, namely in the main stress axes .

Examples

Laminates with two layers

There are endless ways to manufacture laminates that can withstand a given state of stress. However, the state of tension must not change, since otherwise the laminate is no longer stable in terms of net theory. The condition for the two layer angles is:

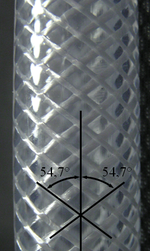

Often one demands that both angles should be of the same size . In this way you always get a balanced angle connection . For the normal stress ratio 1: 2, which occurs in pipes subject to internal pressure ( boiler formula ), this results as an angle (see figure). This angle can be found in practically all wound pipes and containers. However, there are also other angles such. B. possible. These solutions are equivalent.

Laminates with three layers

This case can only be treated if a balanced angle connection and a unidirectional layer are used. In this way it is possible to reduce the number of unknown layer angles and thicknesses so that the system of equations can be solved.

A three-layer laminate is not necessarily optimal. Particular care must be taken to ensure that rules 3 and 4 are not violated. If a layer has a different sign, the laminate is no longer optimal.

Note

The above article is only a brief outline of the properties of network theory. A more in-depth treatment can be found in numerous textbooks on lightweight construction.

literature

- J. Wiedemann: Lightweight Construction, Volume 1 & 2 . Springer-Verlag, Berlin 1986.