Orbital cleaner

An orbital cleaner (also jet cleaner) is a rotating about two axes cleaning device for the cleaning of tanks is used, and other process vessels.

Function of an orbital cleaner

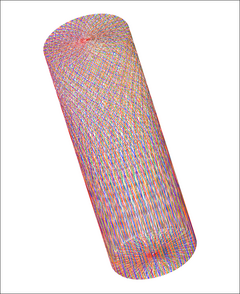

Orbital cleaners rotate around the horizontal and vertical axis . Depending on the type of cleaner, orbital cleaners are equipped with two to four round jet nozzles of different lengths and diameters. The shape of the nozzle creates a tightly bundled jet that ensures intensive treatment of the inside of the tank or container. Orbital cleaners work according to the low, medium or high pressure process and, depending on the pressure and nozzle shape, can achieve horizontal throw distances of up to 15 meters. The cleaner can be driven by a separate drive (such as an electric or pneumatic motor, for example) or by a fluid transmission that is driven by the cleaning medium. Other typical components of an orbital cleaner are the nozzle carrier, housing, inlet with turbine, bearing and the bevel gear. Due to the bevel gear, the jet pattern is shifted by a defined angle after each rotation, so that gradually an increasingly narrow 360 ° mesh pattern is created on the inside of the tank. In hygienic applications, a drainage hole in the lower area of the orbital cleaner is a prerequisite for complete emptying. The cleaners are also equipped with a self-cleaning nozzle.

Application examples

Depending on the pressure and the shape of the nozzle , orbital cleaners can reach horizontal throw distances of up to 15 meters. This makes them particularly suitable for use in large tanks and tanks with complex internals. Due to the high impact pressure on the tank wall, it is also possible to use an orbital cleaner to loosen particularly strongly adhering or difficult to clean products. Orbital cleaners are used in a wide variety of industries, for example:

- Beverage and food industry , e.g. B. fermentation tanks, process tanks, storage tanks

- Sewage industry

- Petrochemical and oil industries

- Paint and varnish industry

Due to the low flow rate and the high power of the cleaner, when using an orbital cleaner, costs in terms of water and detergent consumption as well as energy (see Sinner Circle ) can be saved compared to other cleaning principles. As a result, there is an increasing use of orbital cleaners in various industries.

See also

Individual evidence

- ↑ Falko Fliessbach: Effective tank and container cleaning. Clean as clean can, in: Pharma + Food. Efficiency in the hygiene process, 2013, No. 7, p. 18.

- ↑ Falko Fliessbach: Effective tank and container cleaning. Clean as clean can, in: Pharma + Food. Efficiency in the hygiene process, 2013, No. 7, p. 18.

- ↑ Wolfgang Kunze: Technology brewers and maltsters. 7th edition, VLB Verlag Berlin, 1994, ISBN 978-3-921690-65-9 , p. 498.

- ↑ Falko Fliessbach: Effective tank and container cleaning. Clean as clean can, in: Pharma + Food. Efficiency in the hygiene process, 2013, No. 7, p. 18.