Stirring technology

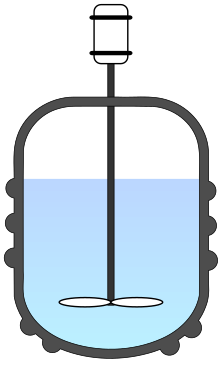

Material and thermal equilibria are established in liquids by mechanical stirring , solutions or dispersions such as suspensions or emulsions are generated.

interpretation

The selection and design of a stirring system can basically be done in two ways.

- In the classic method, the stirring task is simulated on a laboratory scale. Different types of stirrers are tested in real life at different speeds and relevant values such as drive power, mixing quality or temperature increase of the mixture are measured. The results are then extrapolated to the large-scale plant using similarity factors.

- With the help of numerical fluid mechanics (CFD), agitation systems can be simulated in computer models if sufficient physical data is available for the substances involved. This saves time-consuming laboratory tests.

The stirring power P of a stirrer is determined with the aid of a dimensionless performance index Ne (Newton's index) obtained through model tests .

This performance indicator is further dependent on the Reynolds number. The modified Reynolds number for stirring is:

For values above 10,000, the stirred tank is considered to be turbulent. The Reynolds number is calculated to determine the power P. For each form of stirrer there are diagrams from which the performance indicator Ne can be read as a function of Re . P can now be calculated using Ne .

Dispersing

Dispersion is the mixing of at least two substances that do not or hardly dissolve in each other without the input of energy. When dispersing, one substance (disperse phase) is distributed in another substance (continuous phase). In most industrial applications, the goal is to create an emulsion (liquid / liquid) or a suspension (solid / liquid).

An interfacial tension is formed between two phases at the interface. This prevents a dispersion from forming. Due to the energy input of the dispersion, the liquid droplets or solid particles are comminuted to the same size as possible, which results in a balance in the area of the phase boundaries. This brings about a momentary stability of the dispersion, which can be extended by adding emulsifiers or stabilizers.

Homogenize

When a liquid mixture is homogenized, fluid systems with high stability and very fine distribution are created. For the progressive comminution of the particles, accompanied by an increase in the surface area of the particles, the interface energy is primarily decisive for the design of the agitator. Homogenization is typically used for particle sizes below 3 μm.

Thermal engineering

Agitation systems with an integrated temperature control system are used in practice to add or remove heat from the content of the system. The temperature control system usually consists of an internal pipe coil or an external jacket surface which is connected directly to the outer wall of the stirred tank. When intensifying the heat transport in stirred tanks, it must be remembered that the stirring power is converted into heat, which limits the cooling process.

See also

Individual evidence

- ↑ Compare : Vauck Müller; Basic operations of chemical process engineering; P. 377 paragraph 6.1.3; 11th edition; ISBN 3-342-00687-0 .

- ↑ Joshi, JB ET Al .: CFD modeling and mixing in stirred tanks; In: Chemical Engineering Science 54 (1999); Pp. 2285-2293.

- ^ Compare: Werner Hemming; "Process technology"; P. 110; Vogel Verlag; ISBN 3-8023-1488-3 ; 7th edition.

- ↑ Compare : Vauck Müller; Basic operations of chemical process engineering; P. 394 para. 6.1.4; 11th edition; ISBN 3-342-00687-0 .