Rocket Mass Heater

A rocket mass heater (English, literally translated rocket mass heater ; in German sometimes called rocket base furnace ) is a heating furnace that is characterized by a special arrangement of the fuel supply and the flue gas discharge. The basic structure is derived from the rocket stove , but supplemented by a heat accumulator in the manner of a storage or basic furnace . The vertical, cylindrical middle part of the furnace, the "rocket", which gave the furnace its name, is characteristic.

description

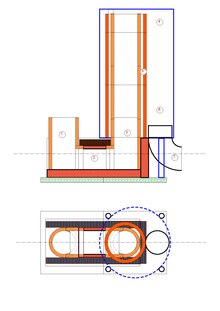

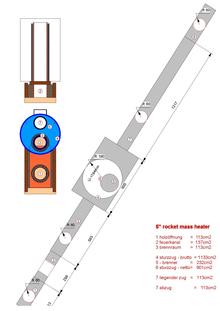

The furnace consists of a fire opening, an L-shaped combustion chamber, the horizontal part of which is the actual combustion chamber (approx. 400–600 ° C) and the vertical part of which is the post- combustion chamber (approx. 1000–1100 ° C). This “burner part” ends in a flue gas expansion part in which the gases cool down by releasing their heat into the environment via the steel boiler. It is a fall draft in which the smoke exhaust gases are further cooled (approx. 90 ° C) and directed into the storage mass. Most of the remaining heat is dissipated in it before the exhaust gases with a temperature of approx. 30–50 ° C are discharged through an exhaust pipe.

The proportions are given in Anglo-Saxon inches . Accordingly, one speaks of a 5 ″, 6 ″ or 8 ″ oven. This denotes the side length dimension of the cross-section and these cross-sectional dimensions are closely related to the respective length dimensions.

Furnace sections

- The filling opening

- The horizontal fire tunnel

- The vertical gas combustion pipe

- The relaxation or cooling chamber

- The storage part

- The exhaust pipe

The filling opening or the filling shaft is aligned vertically. The size determines the fuel input. The wood material burns off in the floor area.

The horizontal fire tunnel opens into the vertical wood gas combustion pipe.

This combustion tube is insulated against the draft with a refractory perlite / clay mixture and ensures the temperature difference in the combustion tube and the cooling part.

This cooling or expansion chamber has a larger cross section than the burner or the subsequent exhaust gas section. This change in cross-section slows down the flow of exhaust gas, which additionally increases the heat dissipation. The cross section of the transition from the combustion chamber to the expansion chamber is described as 1–1.5 ". This distance determines the surface temperature (≥200 ° C) in this area of the cladding tube.

This cooling chamber opens into a storage part, which consists of storage mass (stones, clay, bricks) in order to store the residual heat of the exhaust gases before they escape into the open via the exhaust pipe. Cleaning openings must be installed when changing direction.

Mode of action

The operating principle of this furnace is characterized by the fact that the evacuation of the flue gases is not kept going by the chimney draft , but by the pressure of the hot flue gases in the combustion chamber and is therefore not dependent on the usual flue gas temperature (~ 140 ° in the flue (chimney)) so that this can be very low, which leads to the high heat yield of approx. 1000 ° C➞40 ° C. This creates a self-regulating mechanism that controls the rate of combustion in relation to the prevailing temperature and the resulting pressure. The always open loading opening allows the "correct" air supply for an optimal firing process.

The fuel supply from above and its size limit the amount of burn-up or burn-up surface of the heating material and automatically ensure ideal burn-up due to the constant necessary air supply . Complete, low-pollutant combustion only takes place with sufficient primary air supply; throttling by reducing the air supply worsens the combustion process. With this wood-burning stove principle, the regulation takes place solely through the amount of fuel and not through the air throttling, which means that the wood fuel burns down.

The efficiency

A great advantage of this stove principle is that "inferior" biomass such as branches, tree cuttings, small pieces of wood can be used, and is even an advantage, since the large surface enables very good and quick burn-up - similar to the tufts used in brick-built tiled stoves firmly tied branches and shrub material. This makes this stove principle particularly interesting for people with limited access to good fuels. The measured efficiency is over 90%.

Admission

The principle approval of such ovens is currently not given. Individual permits are possible by means of stove builders or chimney sweepers in compliance with the relevant standards and building regulations. The prescribed fire clearances must be observed. Due to the low temperature of the flue gases after the storage tank, one speaks of exhaust gases, which place lower demands on the pipe material and fire distances.