Sawtooth formation

In connection with the tires of a motor vehicle, especially in the case of car and motorcycle tires, a special form of tire wear is called sawtooth formation . Due to tire characteristics and driving style, but also due to an incorrect axle geometry and defective shock absorbers , there may be irregular oblique wear of tread blocks, which, viewed from the side, is reminiscent of saw teeth.

The tread worn in this way leads to the tire becoming unusable more quickly; it can significantly increase the rolling noise of the tire and impair the driving characteristics of the vehicle. The latter means: the vehicle (regardless of whether it is a car or a truck) is still drivable, but rolls unsteadily (“fluttering” in the steering wheel despite balanced tires).

causes

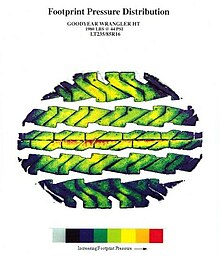

When a tread block hits the road, it is loaded and compressed in the running direction. As the unwinding continues, the tread block is relieved / relaxed. This leads to high slippage movements on the rear edge of the tread block, the result is a sawtooth-like shape of the tread block (mostly in the shoulder area).

prevention

Sawtooth formation can be prevented by regularly replacing the tires (approximately every 5,000–8,000 km) from front to back. If this does not help, you can also try to swap the tires from left to right, which reverses the direction of rotation of the tires, which is not permitted with directional tires. It may also lead to a brief increase in tire wear until the tire has adapted to the reverse direction of rotation. If the tires are not replaced in good time, the durability of the tires can drop to below half due to sawtooth formation: the tires then still have a lot of tread, but are extremely difficult to drive due to the flutter effect mentioned.

remedy

With the help of a precision milling machine, the saw teeth can be removed from the tire. The tire is measured and material is removed from the tread until the tread has returned to normal. However, a lot of tread can be reduced here, which reduces the life expectancy of the tire.

This so-called “leveling” of tires is carried out by some master craftsmen in the vulcanization and tire mechanics trade.

motorcycle

In motorcycle tires, sawtooth formation is a completely normal sign of wear and tear and does not represent a defect. Due to the tires being rounded to the side and the resulting different tire circumferences - in the middle the tire covers a longer distance when rolling than with the side profile parts of its contact area - it occurs permanently to shear forces on the sides, because the rubber in the middle of the contact area is exposed to more contact pressure than on the sides. As a result, the profile shrinks more quickly at the edge of the contact area and, with a corresponding profile, degrades like a sawtooth, so that sawtooth formation is a phenomenon that can hardly be avoided.

Block-like profile structures in the area of the contact area promote the formation of saw teeth and saw teeth are created dynamically through braking and acceleration. In addition, an incorrect setting of the spring damping can cause the tire to suddenly be relieved or stressed too much, as a result of which it is severely deformed and thus also promotes the formation of saw teeth. The air pressure in the tire should also not allow excessive deformations of the tire cross-section. Irregular or one-sided appearance of saw teeth in the profile indicates malfunctions in the area of the chassis.