Vacuum clamping system

Vacuum clamping systems are clamping devices and are used primarily in the wood and plastics industry for quick and easy processing. They are compatible with CNC machines . Vacuum technology is used here in conjunction with special vacuum handling systems, for example to fix a wooden panel to be handled and to process it from all sides. This increases productivity and economy, since the fixation does not cause any damage to the workpiece and the otherwise laborious alignment of the workpiece would take a lot of time.

Newer clamping systems allow the exchange of differently sized and differently shaped attachments in the shortest possible time, which enables flexible handling of the most varied of shaped workpieces.

Operating principles

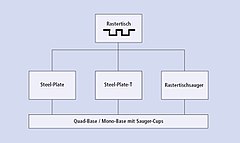

- Grid table : Grid table suction cups can be used very quickly and, thanks to their different overall heights, allow more complex side under-milling and all-round machining.

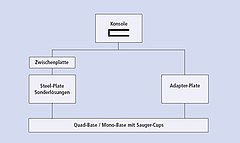

- Smooth table : An intermediate plate is placed on smooth tables, on which either a grid table or a steel plate is located.

- Console : On CNC processing machines with consoles, different suction blocks are used specifically for the 1- or 2-circle system to fix the workpieces.

- Steel-Plate : The Steel-Plate is designed for retrofitting all tables and consoles and enables almost any type of positioning and fixing of a workpiece.

- Examples of different vacuum clamping systems

On the pictures you can see some examples of the different vacuum clamping systems and the vacuum components . These components are mainly vacuum blocks. Because the workpiece is lying directly on you, they may be damaged and thus have to be replaced.