High temperature wool

High temperature wool is an artificially produced material for thermal insulation .

history

Humans have been using fire for thousands of years to melt and heat treat metals. In order to ensure safe handling of fire, special refractory materials were required early on in order to melt metals (copper, bronze, iron) and to process them by hand, which made the handling of liquid or glowing metals possible in the first place. Due to the very different application conditions, a large number of shaped, dense materials (refractory bricks, chamotte ), shaped heat-insulating materials (light refractory bricks ) and unshaped refractory materials (heavy and light ramming compounds) have been developed, each of which is used for special high-temperature applications. For decades, however, other artificially manufactured materials have also been used for thermal insulation, with glass and slag wool being used in the low temperature range (around 200 ° C to a maximum of 500 ° C).

In the 1960s, " ceramic fibers " based on aluminum silicate came onto the market for the first time in the Federal Republic of Germany and very quickly found their way into industrial high-temperature insulation due to their high temperature resistance and good technical properties (e.g. good thermal shock resistance and low thermal conductivity) . The term “ceramic” fiber is misleading, as a whole range of other materials and materials are subsumed under this term. For this reason and because other new materials were developed for the high-temperature range, the nomenclature of the highly refractory nonwovens was redefined at the end of the 1990s. (VDI 3469)

Due to various energy crises (1970s to the present day) and the constantly rising prices for oil and gas, where this was technically possible, energy-saving high-temperature nonwovens were used with increasing frequency. Their use in thermal insulation enabled a lighter construction of industrial ovens and other technical facilities (heating construction, automobiles) with many economic and ecological advantages. This is particularly noticeable in thinner wall thicknesses and significantly lower masses in the infeed.

- Heavy delivery: 1500 to 3500 kg / m³,

- Easy delivery: 500 to 1000 kg / m³,

- Delivery with HTW: 160 to 300 kg / m³.

High temperature wool (HTW)

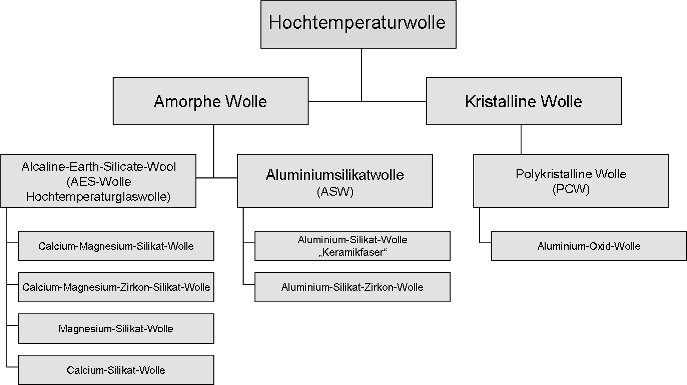

High-temperature wool is a synthetic accumulation of fibers with different lengths and diameters made from mineral raw materials. The group of high-temperature wools with a classification temperature of> 1000 ° C includes amorphous AES and aluminum silicate wools (ASW) as well as polycrystalline wool (VDI 3469; DIN-EN 1094). In addition to the differentiation according to the chemical composition, man-made fibers, in contrast to natural fibers, have parallel edges.

Alkaline earth silicate wool (AES)

The Erdalkalisilikatwollen or English alkaline silicate earth wool are also known as high-temperature glass wool (HTGW). AES wool consists of amorphous fibers that are produced by melting a combination of CaO, MgO, SiO 2 and ZrO 2 (see also VDI 3469, Sheets 1 and 5). AES wools are generally used at operating temperatures <900 ° C and with continuously operating units and in the household appliance sector. Alkaline earth silicate wools were developed in the early 1990s.

Aluminum silicate wool (ASW)

Aluminum silicate wool, also known as ceramic fibers ( English Refractory Ceramic Fiber = RCF), are amorphous fibers that are produced by melting a combination of Al 2 O 3 and SiO 2 , usually in a weight ratio of 50:50 (see also VDI 3469 sheets 1 and 5 and TRGS 521). Products made of aluminum silicate wool are generally used at operating temperatures> 900 ° C and with periodically operating units and critical application conditions (see TRGS 619). Aluminum silicate wool has been used since 1952.

The aluminum silicate wools are carcinogenic substances of category 2 (according to the Ordinance on Hazardous Substances, GefStoffV ) "Substances that should be regarded as carcinogenic for humans." There are sufficient indications to assume that human exposure to the substance can cause cancer . (see under literature: " Are fibers from catalytic converters / diesel particulate filters released into the environment that could pose a risk to the general public? ")

Polycrystalline wool (PCW)

Polycrystalline wools consist of fibers with an Al 2 O 3 content> 70% by weight; they are produced from aqueous spinning solutions using the “sol-gel process”. The initially created water-soluble green fibers (preliminary product) are crystallized by subsequent heat treatment (see also VDI 3469 sheets 1 and 5). Polycrystalline wools are generally used at operating temperatures> 1300 ° C and also at lower temperatures under critical chemical and physical application conditions. Polycrystalline wool has been manufactured since the early 1970s.

Definitions

Classification temperature

The classification temperature is defined as the temperature at which a linear shrinkage of 4% is not exceeded after 24 hours of heat treatment in an electrically heated laboratory furnace and in a neutral atmosphere. Depending on the type of product, the value must not exceed the following limits: 2% for panels and molded parts, 4% for mats and papers. The classification temperature is given in 50 ° C steps (starting at 850 and up to 1600 ° C).

Classification temperature does not mean that the product can be used continuously at this temperature. In practice, the continuous operating temperature of amorphous HTWs (AES and ASW) is typically 100 ° C to 150 ° C below the classification temperature. Products made from polycrystalline wool can generally be used up to the classification temperature.

Want

Wool is a disordered accumulation of fibers with different lengths and diameters. "High temperature wool" fulfills this definition and therefore falls under the term "wool".

Amorphous AES and aluminum silicate wools are produced by melting the raw materials in a melting tank using an electrical resistance melting process. The melt jet emerging at the bottom of the tank is accelerated by means of a blowing process or a centrifugal process and drawn into fibers with different length / diameter ratios.

Continuous fibers / textile glass fibers (VDI 3469 sheet 1)

These fibers are produced by means of a nozzle drawing process with defined nozzle diameters; all monofilaments have the technically specified desired diameter. When handling, only fibers of the given diameter but of different lengths are released. By definition, high temperature wool is not a fiber, so the term ceramic "fiber" is incorrect.

Textile yarn

Through textile working processes, yarns can be made from wool, which can be processed into a wide variety of products (cords, ropes, cloths, clothing). High-temperature wool can also be processed into textiles. The result is high-temperature-resistant cords that are used, for example, for seals, cloths (fire protection blankets) and heat-protective clothing.

Applications

The HTW are assigned to special areas of application due to their working temperature. These can shift in individual cases due to special conditions (atmospheric, physical conditions, service life requirements). Every application places special, very special requirements on the refractory material. If these requirements are met, the most suitable product can be selected for this case. Some typical applications of HTW products are shown below as examples. The HTW products are usually supplemented with traditional refractory products in order to have a complete solution.

Alkaline earth silicate wool

The main focus of the application of this wool is in the field of household appliance technology (e.g. thermal insulation of ceramic hobs, microwave and baking ovens), but also in the field of automobile construction (e.g. storage mat for diesel soot particle filters) and heating construction. In industrial applications, the products are mostly used in temperature ranges below 1000 ° C, including in the non-ferrous metal industry.

Aluminum silicate wool

Aluminum silicate wool is a product for thermal insulation in industrial areas, essentially at working temperatures of 800 ° C to 1300 ° C. The main focus of their use are wide areas of industrial furnace, furnace and heating construction, in hot gas filtration , in automobile construction in the hot-end area of exhaust systems and as storage mats for catalytic converters and diesel soot particle filters (DPF).

Polycrystalline wool

The application temperature when using products made from PCW is mainly over 1300 ° C. This results in special applications in the industrial sector at temperatures of up to 1800 ° C or in which chemical resistance is required.

In the ceramic industry (this also includes porcelain), for example, full PCW modules are used as thermal insulation in industrial furnaces and in the laboratory furnace technology, molded parts made of PCW are used to insulate the furnace. B. dentures is used.

However, it can also be used in lower temperature ranges. As a result, repair intervals of industrial furnaces are extended by z. B. the ASW thermal insulation is completed by expansion joints made of PCW, furthermore combination modules (PCW / ASW) are gaining increasing attention in industrial furnaces in the steel industry.

advantages

Saving of resources

Compared to classic thermal insulation materials such as lightweight refractory bricks (calcium silicate and microporous materials), heavy bricks (firebricks and masses) and refractory concretes, high-temperature wool (HTW) as thermal insulation materials can lead to energy savings in many heating processes:

- in the production and processing of steel and non-ferrous metals.

- in industrial furnace, furnace and heating construction

- in automobile construction, especially in the hot-end area of exhaust systems, as storage mats for catalytic converters and diesel soot particle filters

- in the ceramics industry

- in hot gas filtration

- but also in household appliance technology (such as thermal insulation of ceramic hobs, microwaves and ovens).

Compared to traditional thermal insulation materials, high-temperature wool has a number of economic and environmental advantages. Since every application of HTW products is an individual solution, specific advice is required. The user must present the requirements of his thermal process and the HTW distributor can select the appropriate HTW product based on this requirement profile.

For example, in the steel / non-ferrous metal industry, in industrial furnace / furnace / heating construction and in the ceramics industry, energy savings of up to 50% are possible compared to conventional stone / concrete linings. This is associated with an improvement in the efficiency of the thermal processes and a reduction in CO 2 emissions. Industrial furnaces and systems with HTW thermal insulation have further advantages due to the lighter steel construction and significantly lower weight of the HTW lining, lower requirements for the foundations, and quick assembly / maintenance / repair of the system. HTW systems can be heated up and cooled down faster. This increases availability and thus productivity, especially in the case of discontinuous processes.

Health hazards from dust

Since, in contrast to mineral wool insulation materials, no dust binding agents are added to HTW products, an increased amount of dust is to be expected when processing and using them. The group of dusts also includes fiber dusts that can arise during the treatment and processing of artificially produced inorganic mineral and high-temperature wool. The fiber dusts with a length of more than 5 µm, a diameter of less than 3 µm and a length / diameter ratio that is greater than 3: 1 are considered to be respirable. Respirable fiber dust can be released from high-temperature wool and from textile products made of this wool. Accordingly, handling regulations must be observed that are drawn up and published by the Federal Ministry of Labor and the associations of manufacturers of high-temperature wool.

literature

- DIN EN 1094-1: Fireproof products for thermal insulation purposes - Part 1: Terminology, classification and test methods for products made from high temperature wool for thermal insulation; German version EN 1094-1: 2008

- VDI guideline: VDI 3469 sheet 1 - overview

- VDI guideline: VDI 3469 sheet 5 - high temperature wool

- Gas heat, high temperature wool Neglected innovation in refractory construction

- List of MAK and BAT values from the German Research Foundation

- High temperature wool in modern industrial furnace construction (PDF; 1.1 MB)

- Are fibers from catalytic converters / diesel particulate filters released into the environment that could pose a threat to the general public? (PDF; 5.2 MB)

Web links

- BAuA - Federal Institute for Occupational Safety and Health

- ECFIA - European Association representing the High Temperature Insulation Wool Industry (English)

Individual evidence

- ↑ a b c Heinz Wimmer: High temperature wool (HTW): Use opportunities - avoid risks. In: Hazardous substances - cleanliness. Air . 68, No. 11/12, 2008, ISSN 0949-8036 , pp. 455-460.

- ↑ VDI 3677 sheet 3: 2012-11 Filtering separators; Hot gas filtration (filtering separators; high-temperature gas filtration) . Beuth Verlag, Berlin. P. 15.

- ↑ Norbert Kluger: Prevention - measures for activities with high-temperature wool. In: Hazardous substances - cleanliness. Air. 68, No. 11/12, 2008, ISSN 0949-8036 , pp. 461-467.