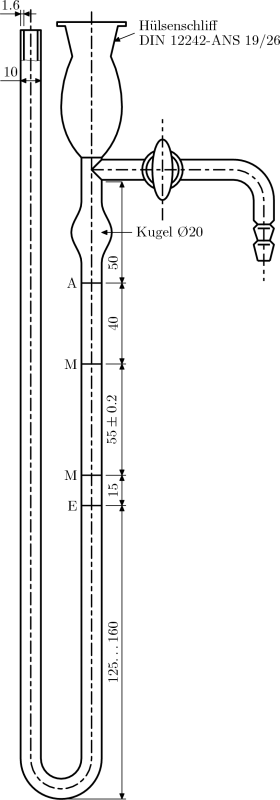

Blaine device

With the help of the Blaine device , the specific surface area of a powder can be determined by measuring the time it takes a given amount of air to flow through a certain amount of powder. This measurement is based on the Carman-Kozeny equation , which establishes a relationship between the specific surface area , the pressure difference across a bed , the porosity of a bed and the flow velocity :

| Formula symbol | unit | meaning |

|---|---|---|

| m 2 / m 3 | volume-related specific surface | |

| - | constant | |

| Pa | Pressure difference | |

| m 3 / m 3 | porosity | |

| m | Length of the flow path | |

| Pas | dynamic viscosity of the fluid | |

| m / s | Flow velocity |

After transforming the equation, the relationship is obtained for the pressure drop that varies over time

To determine the surface, a porous system with a certain mass and porosity is produced from the solid to be examined . It opposes a flow resistance to gases , which u. a. depends on its specific surface.

A certain volume of air is sucked through the system and the time required for this is measured by the column of liquid, which is deflected from the rest position in a U-tube arranged under the porous system .

From the measured time, the viscosity of the air, the porosity and the density of the solid, the specific surface is calculated according to the above equation.

Since the Carman-Kozeny equation is quite generalized, the calculated surfaces are only suitable for comparison purposes of similar materials or control purposes of a single powder. If the grain size distribution is wide , the material should be classified into several grain fractions and these should be analyzed individually. The device constant is determined by calibration with a substance of known surface and density.