Forced flow boiler

A once- through boiler is a steam generator of the type water tube boiler with superheater , in which the flow of water / steam is forced through a feed pump . This type of boiler was first realized as a Sulzer and Benson boiler in the 1920s.

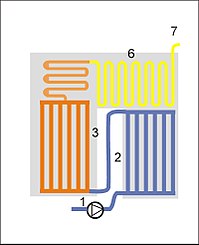

The feed water is pumped into the boiler and flows through the feed water preheater , the evaporator and the superheater one after the other . The heating of the feed water up to the boiling point , the evaporation and overheating take place continuously in one pass, so that no drum is required.

Sulzer boiler

The Sulzer boiler is operated in the subcritical pressure range of water, the amount of feed water being constant. A desalination tank is used at the link between the evaporator and superheater. Originally the separated water was discarded. Since nowadays only fully demineralized and monitored feed water is used, the container is used as a water separator in new designs. A pump conveys the separated water directly back into the feed water preheater. With a high boiler output, there is no water in the separator, while in the output range <70% a certain amount of water is separated and works as a forced-flow mixing system . The control and performance adjustment in the superheater area is carried out by injection coolers .

Benson boiler

The Benson boiler, named after its inventor Mark Benson (patent 1926/27), is mostly operated in the supercritical range. The feed pump brings the feed water to a pressure of over 230 bar. The amount of feed water is regulated depending on the load. When heating up, there is no longer any evaporation if the operating mode is supercritical. Strictly speaking, the definition of the individual heating surfaces, feed water preheater, evaporator and superheater, no longer makes sense for the operating mode, since the phase transition no longer takes place. The Benson technology is licensed worldwide from Siemens .

Modern steam generator

A modern power plant is run in start-up mode and at low load (below the so-called Benson point ) in forced circulation or Sulzer mode. In normal power operation or from the Benson point onwards, a switch is made to forced throughput or Benson operation.

Summary

With once-through boilers, very high steam outputs can be generated in a relatively small space. The pipes can have a small cross-section due to the forced convection . Since the boiler type does not have a drum, the amount of water in the system is relatively small and therefore the system has little inertia . With the adjustable parameters of the feed water quantity or water separation with superimposed circulation or the injection control on the superheaters, it is possible to react quickly to load changes.

Since the boiler type does not have any components with a larger diameter, very high pressures can be operated and thus very high levels of efficiency can be achieved. Today's designs allow a pressure of 290 bar and a superheated steam temperature of 600 ° C. The amount of steam generated can be up to 3000 t / h .

See also

Individual evidence

- ↑ BENSON waste heat boiler ( Memento from November 14, 2007 in the Internet Archive )