Own use (power plant)

In all types of power plants, the internal units have an energy requirement that the power plant must initially provide itself. This so-called own requirement takes up a few percent of the terminal output of the generator (= gross output).

The feed pump usually accounts for a large proportion of the internal requirements in steam power plants . It is driven either by its own steam turbine or by an electric motor. Other items of this type are the main cooling water pumps. In coal-fired power plants, the drives for the coal mills , fresh air and induced draft fans, the e-filters and the numerous circulation pumps in the flue gas cleaning system also play a role.

The electrical consumption varies depending on the type of power plant. For coal-fired power plants it is between 4% and 10%, for nuclear power plants between 5% and 16%. The smaller values are typical for larger power plants. Smaller diesel power plants have an internal requirement of 3% to 5%, while larger diesel power plants have up to 8%. Hydropower plants and gas turbine power plants have a very low internal requirement of around 1% - these power plants may therefore manage without their own medium-voltage level . The in-house requirement is even lower for wind turbines , where the own requirement accounts for around 0.35 to 0.5% of the electrical energy produced.

Energy sources for personal use

There are different concepts to cover own requirements: In power plants with only one block it is common to draw the own demand power from the main turbine via the electrical generator while the power plant block is in operation . When starting and stopping the block, the supply usually comes from the network, which means that there is no black start capability. The start-up can take place via the machine transformer and the auxiliary transformer if there is a generator switch to separate the generator and the machine transformer and the network can cover the considerable reactive power requirement of the machine transformer. Otherwise, separate start-up transformers establish the connection between the internal supply network and the public network.

The self-supply from a neighboring block is possible both for start-up and via a so-called "house machine" even during power operation. The house machine refers to a - mostly small - block in a block power plant that only feeds the internal supply rails of the other blocks.

In nuclear power plants , the self-supply from the main turbine via the electrical generator is almost the only method used. The emergency power generators also available at nuclear power plants serve to supply the emergency power rails in the event of failure of the power supply rails; They are not designed to supply the much more powerful self-consumption consumers such as feed water or coolant pumps.

Structure of self-supply

In order to be able to supply the numerous consumers with very different connection loads and functions, the power plant's internal power supply consists of several internal supply rails at different voltage levels:

coal-fired power station

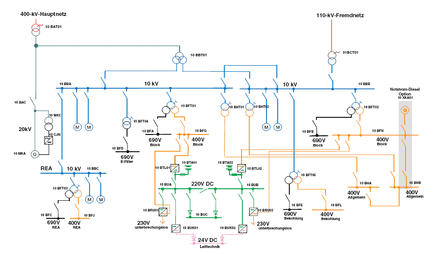

Example based on a modern German coal-fired power plant (1–2 × machine transformer (MT), 2 × internal transformer (ET), 1 × generator circuit breaker (GLS), 1 × mains circuit breaker (NLS)):

- 4 internal switchgear 10 kV ( * 0BB * ) supply the largest consumers (fresh fans, induced drafts, feed water, condensate, circulation and cooling water pump (s) ...). These power supply rails are supplied with voltage in two ways: When the power plant is operating, the power supply transformers establish a connection to the voltage level of the generator and take the power required by the generator output (voltage 27 kV, low voltage side 10 kV). During a standstill, the internal supply rails are supplied "backwards" via the machine transformers from the high-voltage network (the GCB separates the generator from the machine transformers). For inspection purposes, there is an external power supply that is not designed for start-up.

- Several transformers take energy from these uppermost auxiliary switchgear and supply additional auxiliary switchgear at voltage levels of 700 V and 400 V , which in turn serve to supply the numerous low-power drives.

- Emergency power switchgears ( * * BM * ) supply loads that need to be supplied with electrical energy during faults. In undisturbed operation, these are connected to the power supply rails of the corresponding voltage, but if the power supply network fails, they are disconnected from them and supplied from other sources, for example from another network connection or from fast-starting diesel generators. Due to the network switchover or the start delay of the diesel engine, there is also a power failure of a few seconds, which is not critical for many emergency power consumers.

- Uninterruptible switchgear ( * * BR * and * * BU * ) are used to supply even briefly indispensable consumers (emergency lighting, emergency oil supply to the turbine, control technology). They are supplied by several UPS (batteries with downstream inverters) or direct battery feed.

- Emergency diesel generator (s) supply the emergency power switchgear and, via this, the uninterruptible switchgear in the event of a power failure (blackout) .

Nuclear power plant

The structure is very similar to that in the coal-fired power plant; the higher self-consumption capacity and higher safety requirements require comparatively small changes. The structure is explained below using the example of a modern German nuclear power plant with a pressurized water reactor:

- Four internal supply rails of 10 kV supply the largest consumers (main coolant, feed water, condensate and cooling water pumps) directly. Each of the four main coolant pumps is assigned its own individual requirements. These power supply rails can be supplied with voltage in various ways: When the power plant is in power mode, the power supply transformer establishes a connection to the voltage level of the generator and draws the power required by the generator output (voltage 27 kV). It is designed as a three-winding machine with one high-voltage and two low-voltage windings. One low-voltage winding each supplies two power supply rails. Alternatively, the power supply rails can be supplied from the public grid via two starting transformers; the 110 kV grid level is usually used for this. The start-up transformers are also designed as three-winders with two low-voltage windings; here, each low-voltage winding is assigned an individual supply rail.

- Further transformers take energy from these top internal supply rails and supply other internal supply rails at voltage levels of 660 V and 400 V , which in turn serve to supply the numerous auxiliary drives with lower power.

- Four emergency power rails supply loads that need to be supplied with electrical energy during faults. In undisturbed operation, these are connected to the power supply rails for the corresponding voltage, but if the power supply network fails, they are separated from them and supplied from other sources. A fast-starting diesel generator is assigned to each emergency power rail. It is also possible to supply the emergency power rails via an emergency power supply connection. Due to the network switchover or the start delay of the diesel engine, there is also a power failure of a few seconds, which is not critical for many emergency power consumers. These include emergency cooling and emergency feed systems.

- An uninterruptible power supply also serves to supply indispensable consumers for a short time (emergency lighting, emergency oil supply for the turbine, control technology). It is realized by batteries that are charged and recharged by rectifiers from the emergency power rail. Numerous I&C consumers use the DC voltage from the batteries directly, three-phase consumers are supplied by rotating converters or converters from the batteries.

literature

- René Flosdorff , Günther Hilgarth: Electrical energy distribution . 8th edition. Teubner, 2003, ISBN 3-519-26424-2 .

Individual evidence

- ↑ E. Pick, H.-J. Wagner, contribution to the cumulative energy consumption of selected wind energy converters. Report of the Chair for Energy Systems and Economics , University of Bochum 1998, p. 20.

- ↑ Scharndorf-West wind farm: detailed information (PDF; 91 kB). Info brochure. Retrieved November 9, 2013.