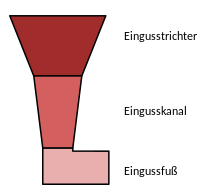

Sprue

As a sprue in which is foundry technology an element referred to, which comprises filling the melt from furnace or ladle into the mold easier. The sprue can be placed on the side of the mold, on the top box or in the mold itself. The sprue is part of the sprue-barrel-gate system and is mostly used for sand casting , but also for permanent mold casting .

Components

There are a large number of sprue types, each optimized for the shape used. For most sprues for sand molds, the sprue can be divided into three parts: The sprue marks the start of the sprue, the sprue is at the end of the sprue and the sprue is between the sprue and the sprue.

Pouring funnel

The pouring funnel is cone-shaped and widens towards the top. In addition to making it easier to pour in the melt, it ensures that the melt gets into the molds without interruption, as its volume allows it to compensate for fluctuations in the filling speed. In order to make pouring funnels in sand molds, many molding machines have pouring bores or pouring mills.

From ceramic existing Eingusssiebe or inlet filter can be inserted and serve as retention of the sprue furnace slag . Sprue sieves and sprue filters are available in different opening sizes with which the flow velocity behind the pouring funnel can be influenced.

A pouring pool can also be located at the point of the pouring funnel. In contrast to the pouring funnel, the pouring pool is trough-shaped; the opening to the sprue is smaller than the base of the tub.

Sprue

The sprue is the link between the sprue and the sprue and should not be confused with the runner-gate system. The sprue is positioned vertically and tapers downwards to prevent air being drawn in and the creation of turbulence. This increases the flow velocity of the melt along the runner and reaches its highest value at its lowest point.

Sprue

The sprue serves as the transition from the sprue to the runner and reduces the flow velocity following the sprue. This effect can be achieved in several ways:

- Deflection of the melt by 90 ° in combination with an enlarged cross-section

- Insertion of a filter that slows down the melt with its opening size

- Insertion of a core that has to be washed around by the melt on both sides

literature

- Ernst Brunhuber (Ed.): Giesserei Lexikon. Fachverlag Schiele & Schön, 16th edition, Berlin 1994, ISBN 3-7949-0561-X , pp. 998-1004.