Fed batch process

Fed-batch process ( English fed “fed” and batch “stack” or “batch”) also feed process is an established term in process engineering . This is used to describe batch processes that are processed as “stacks”, i.e. one after the other, and that are operated by an inflow (feed) of educts up to the maximum fill level. In contrast, there are batch processes and continuous processes .

Another term commonly used in process engineering is “semi-batch”. In this case, the removal of starting material can also be meant during the batch procedure, e.g. B. in a batch distillation.

Temporal course

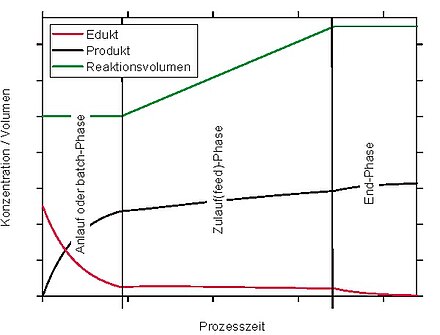

A typical fed-batch process has the following timing:

- partial filling of the reaction vessel with the starting materials ( starting materials )

- Reaction of the starting materials to products . Starting at a defined concentration, the starting material is now "fed in". An attempt can be made here to keep the reactant concentration constant in the reactor, or a constant feed stream is supplied.

- Emptying the reaction vessel (harvest) and forwarding the products to the downstream process

- Preparation of the reaction vessel for the next filling (cleaning, maintenance)

Accounting

Material balance

For the change of the molar amount , the reaction volume , the fabric rates of change , the flow rate at the input of the system and the molar concentrations of the feed stream in the reactor or in the following applies:

In contrast to continuous and discontinuous operation, the reaction volume is variable over time:

thus:

- With

you get:

- or.

advantages

On the one hand, the fed-batch process offers the possibility of limiting the reaction rate to a certain level by keeping the reactant concentration low, which offers the advantage, particularly in the case of strongly exothermic reactions, of completely dissipating the heat of reaction . The fed-batch method is most frequently used in the cultivation of microorganisms ( fermentation ). A substrate inhibition of the growth rate can be prevented by a low substrate concentration . In contrast to the batch process , in which the final concentration of biomass is dependent on the initial substrate concentration due to the stoichiometry, significantly higher final concentrations of biomass and thus also of product can be achieved here. Likewise, with a substrate-limited fed-batch process, the risk of secretion of (often toxic) secondary metabolites (overflow products) is reduced. In contrast to the simple batch process, the growth rate can be regulated in a fed-batch process, which can significantly improve the reproducibility of fermentations.

disadvantage

In contrast to batch processes, the reaction volume is variable over time; a balancing of the state variables is therefore necessary if such a process is to be modeled and simulated. If the modeling succeeds, the same problems arise with the scale transfer as with the simple batch process. In order to be able to use the advantages of a fed-batch process, in addition to the necessary modeling, the technical requirements for the controlled or regulated feed operation are necessary. In order to regulate the educt concentration at a constant level, for example, appropriate online measurement data on the one hand and precise feeding on the other hand are necessary.

Individual evidence

- ↑ J. Ljunggren, L. Häggström. 1992. Glutamine limited fed-batch culture reduces the overflow metabolism of amino acids in myeloma cells. Cytotechnology 8, 45-56.

- ↑ S. Gnoth, M. Jenzsch, R. Simutis, A. Lübbert. 2008. Control of cultivation processes for recombinant protein production: a review. Bioprocess and Biosystems Engineering 31, 21-39.