Fixed bed reactor

A fixed bed reactor is a special form of reactor in which one or more fluids flow through a solid bed or packing. The fixed bed is often used to fix heterogeneous catalysts or - in the case of bioreactors - the microorganisms . The chemical or biological catalyst can be in the form of superficial, coated but solid bodies (often spheres but also cylinders and more complex geometries) or porous media of the same kind.

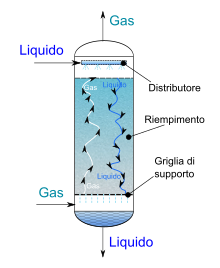

The fluids can flow through fixed bed reactors from above as well as from below and in opposite directions. Especially in the case of a liquid and a gaseous phase, we speak of trickle beds or trickle bed reactors. Here the liquid phase flows through the reactor from top to bottom and the gaseous phase is the continuous phase. In contrast to this, we speak of packed bubble columns when the gas flows through the packing from bottom to top and the liquid phase is the continuous one. Other material flow combinations are the exception in industry.

The main advantage of the fixed bed reactor compared to reactors with dissolved catalyst is that the catalyst does not have to be separated from the product and therefore a filtration step is not required.

The main disadvantage compared to reactors with a dissolved catalyst is that additional resistance occurs, particularly in the transport of substances and heat.

If the biocatalysts are immobilized by binding to particulate carrier materials, it is a fluidized bed reactor . Since a fluid-solid mixture is present here, it is a fluidized bed process .

literature

- Horst Chmiel: Bioprocess technology. 2nd Edition. Spektrum Akademischer Verlag, Munich 2006, ISBN 3-8274-1607-8 .