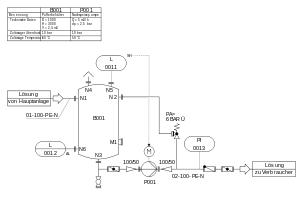

R&I flow diagram

Piping and instrumentation diagram denotes an R ohrleitungs- and I nstrumenten flow chart in the plant and process technology (including R + I-flow diagram, R & I scheme, R & I Chart, R + I-flow diagram English Piping and Instrumentation Diagram or P & ID ).

Content and task

The P&ID flow diagram is created on the basis of the basic flow diagram. In the P&I flow diagram, all components required for the operation of a system, such as tanks , apparatus , pumps , compressors , heat exchangers (heat exchangers), pipes , fittings and measuring devices , are symbolically represented.

All lines that represent a pipeline are marked with nominal width, nominal pressure, medium, pipe class and an identification number.

It is similar for the definition of measurement and control technology . Standardized symbols (ovals) define where and what is to be measured or controlled. These also receive an identification number for further processing. Control loops are shown with action lines (from the installation location of the measurement to the actuator).

The schema contains the following information:

- Type and designation of the apparatus and / or machines

- Pipelines, fittings with nominal widths, pressure levels, materials

- Drives

- Tasks of the facilities for measuring, controlling, regulating

Additional information can be given, e.g. B. heights of the apparatus, other materials, other designations (e.g. of fittings).

After approval of the P&ID flow diagram by the customer (and possibly also by the authorities), the detailed planning (detail engineering) begins, which includes the installation and piping plan .

R&I flow diagram according to ISO standard

In Germany, P&ID flow charts are shown in accordance with DIN EN ISO 10628. Further pipe symbols can be found in DIN 2429 (withdrawn). Action lines of control and regulating organs are shown in accordance with EN 62424 and ISO 3511 .

| pipe | insulated pipe | Tube with protective jacket | heated or cooled tube | ||||

| Container ( chemical reactor ) with jacket | pressure vessel | Container with half-pipe coil | column | ||||

| Pump (general) | Compressor , compressor , vacuum pump (general) | bag | Column with exchange trays | ||||

| fan | Axial fan | Centrifugal fan | gas bottle | ||||

| Furnace , kiln | Cooling tower | Dryer , evaporator | cooler | ||||

| Heat exchanger | Heat exchanger | Plate heat exchanger | Spiral heat exchanger | ||||

| Jacketed heat exchanger | Shell and tube heat exchanger | U-tube heat exchanger | Finned tube heat exchanger with axial fan | ||||

| Overcurrent opening | Overcurrent opening | filter | funnel | ||||

| Condensate drain | Sight glass | Pressure reducer | tube | ||||

| Shut-off valve | Control valve | manual valve | Check valve | ||||

| Needle valve | Butterfly valve | Diaphragm valve | Ball valve | ||||

| Angular safety valve, spring-loaded |

Mixing valve or diverting valve |

Identification letters and marking

The standards EN 62424 / ISO 3511 and ISA 5.1 are used to mark measuring and control points.

The comprehensive labeling of all apparatus, pipelines and instruments in industrial systems is described in EN 81346 ( industrial systems, systems and equipment and industrial products - structuring principles and reference labeling ) or in the national standard DIN 6779 ( labeling system for technical products and technical product documentation ). There all measuring and control points are assigned to main group B. The code letters according to ISO 14617-6 are also used for the subgroups.

In the field of power plant construction, the components (apparatus, pipelines and instruments) are marked according to the power plant identification system (KKS) or according to the new system for marking (coding) power plant components (RDS-PP).

Measuring and control points

The measuring and control points are represented in accordance with ISO 3511. There is no German translation of ISO 3511. The previously valid DIN 19227-1 was replaced by the European standard EN 62424 in January 2010.

Description of the abbreviations

According to DIN 19227-1, measuring points were designated with an abbreviation consisting of one or more letters and an identifier (usually a sequence of digits). The sequence of letters provides information about the function and task of the measuring point and consists of a first letter and possibly one or more additional letters and subsequent letters.

EN 62424 uses the term “PCE category” instead of “first letter”, supplementary and subsequent letters (which anyway do not overlap) are included in the so-called “PCE processing function” (PCE = Process Control Engineering). The current standard adopts most of the letter meanings, but also adds new ones and redefines some of the existing ones.

One cannot and does not want to specify all the details with this designation system. A reference to the instrument data sheet is given together with the identification number. There you can read the measuring range, level of the limit values, details on installation and much more.

First letter - PCE category

- A analysis

- B Optical measurement, e.g. B. Flame supervision

- C Unrestricted use

- D density

- E Electric voltage

- F flow

- G Distance, length, position

- H manual input, manual intervention

- I Electric current

- J Electrical power

- K Time-based function

- L level

- M humidity

- N controller, actuator with electric actuator (all electrical consumers, e.g. motor, heater)

- O freely usable

- P pressure

- Q Quantity, number or quality (analysis values, material properties)

- R radiation quantities

- S speed or frequency (including acceleration)

- T temperature

- U Used for a PCE control function

- V vibration, mechanical analysis, torque

- W weight, mass, strength

- X Freely usable (The unclassified letter "X" is intended to cover meanings that are not listed.)

- Y controller, actuator with non-electric actuator, e.g. B. hydraulic or pneumatic (open / close, control valve or throttle point (orifice))

Follow-up letter - PCE processing function

- A Alarm, message (alarming)

- B restriction, limitation

- C regulation / control (controlling)

- D Difference

- F Ratio (Fraction)

- H upper limit, on, open

- I Analog display (indicating)

- L lower limit, off, closed

- O visual signals, yes / no display (no fault message)

- Q running total / integral (e.g. for total flow) (Quantity)

- R Storage / Recording (Recording)

- S Binary control function or switching function (not safety-relevant) (switching)

- T transmitter, for analog value processing (monitoring)

- Y arithmetic function

- Z Binary control function or switching function (safety-relevant) (emergency)

Remarks:

- The letters I and R refer to the result of the preceding processing function.

- The PCE processing functions A, H, L, O, S and Z may only be used to the right outside the oval.

- If the following letters are combined, proceed in the order in the following overview in rows 1 and 2 from left to right and in rows 1 and 2 from top to bottom: Row 1: FDYC Row 2: BQX

Examples

- PI-512: Pressure display

- PDI-512: pressure difference display

- PICAH-512: Pressure control with display with alarm if an upper limit value is exceeded

- F-100: current flow

- FQ-100: total amount flowed through

- TIRCSHAHL-618: Temperature control with display, storage, switching when the upper limit value is reached and alarm when the upper and lower limit value is reached

Programs for creating P&ID flowcharts

Programs from the field of computer-aided engineering (CAE German: Computer-assisted planning) are increasingly being used to create P&ID flowcharts in plant construction . The applications provide the flow chart symbols in standardized size and line width and support their placement. Lists are provided for labeling and it is ensured that the correct label format is adhered to (especially important for KKS). The data is usually stored centrally in databases. This enables the data to be evaluated later.

Overview of applicable standards

Status: February 2020

- ISO 3511-1: 1977-07: Measurement, control, regulation in process engineering; Symbols for functional representation; Part 1: basic requirements

- EN ISO 7200 : Document writing field (old DIN 6771-1 )

- DIN EN ISO 10628-1: 2015-04: Schemes for the chemical and petrochemical industry - Part 1: Specification of the schemes

- DIN EN ISO 10628-2: 2013-04: Schemes for the chemical and petrochemical industry - Part 2: Graphic symbols

- ISO 15519-1: 2010 (en): Specification for diagrams for process industry - Part 1: General rules (basic standard for ISO 10628)

- DIN 19227-2: 1991-02: Control technology; Graphic symbols and letters for process control technology; Presentation of details

- DIN 28000-4: 2014-07: Chemical apparatus engineering - Documentation in the life cycle of process plants - Part 4: Graphic symbols for fittings, pipes and actuators (replaces DIN 2429-1 and DIN 2429-2)

- DIN 28000-5: 2015-04: Chemical apparatus construction - Documentation in the life cycle of process plants - Part 5: Graphic symbols for apparatus and machines

- EN 60617: Graphic symbols for circuit diagrams (old DIN 40900)

- EN 62424: Representation of tasks in process control technology - flow charts and data exchange between EDP tools for flow chart creation and CAE systems (old DIN 19227-1)

- DIN EN 81346-2: 2010-05 : Industrial systems, plants and equipment and industrial products - Structuring principles and reference designations - Part 2: Classification of objects and identification letters of classes

American standard R&I flow diagrams

Differences to the European standard

In the United States, P&ID flowcharts are based on the Anglo-American measurement system . Symbols are represented according to the American standard ISA .

This standard does not have as strict a system as EN ISO 10628. Symbols for apparatus and equipment are shown according to their actual appearance. Among other things, this means that the symbols for centrifugal pump and radial fan are very similar. Straight-through fittings are shown explicitly according to their functional principle, similar to the ISO standard, but no precise specification is made for corner fittings and multi-way fittings (no symbols for corner tap, corner valve).

Instruments are not presented in a summarized manner, but are explicitly split up according to individual functions.

Example of a flow measurement with display, control and recording:

- ISO: FIRC

- ISA: FT-FI-FR-FC

In technical drawings of international projects there are often mixed markings.

Number plate structure according to ISA 5.1

First letter

- A analysis

- F- flow (flow)

- P- pressure

- T temperature

- Z position

Second letter

- T transmission (transmitter)

- R recording (recorder)

- I- display (indicator)

example

Flow transfer from control circuit 1000A

Function identification

- First letter F

- Second letter T

Control loop identification

- Control loop number 1000

- Suffix A

FT 1000A

Further examples

- PT 1000A pressure transmission 1000A

- PI 1000A pressure indicator

- PIC 1000A pressure controller with display PID control circuit

- PIRC 1000A pressure regulator with recording and display

See also

Web links

- Dia - open source program for drawing structured diagrams.