Plate heat exchanger

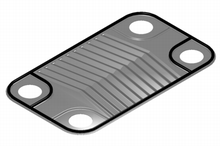

A plate heat exchanger (PHE) - often also referred to as a plate heat exchanger (PHE) or plate cooler (PK) - is a special design of a heat exchanger . It consists of wave-shaped profiled plates, which are put together in such a way that the medium to be heated up and then the heat-emitting medium flows in the successive gaps . The plate package is sealed to the outside and between the media and is held together with clamping screws, for example.

Due to their special construction, (screwed) plate heat exchangers are very expandable and very flexible with regard to the design of the flow guidance, which is determined by the position of the seals.

Designs

A common design are soldered plate heat exchangers. With this design, the individual plates are soldered together so that the tensioning screws can be dispensed with. In the event of defects within the plate pack, however, individual plates can only be exchanged if they are screwed on. Soldered plate heat exchangers must be completely renewed in the event of such a defect.

Another design consists of laser-welded cassettes (LWC = Laser Welded Cassette). Here, two plates are welded with a laser to form a gas-tight cassette. The plate pack is clamped together with clamping screws so that dismantling or expansion is possible at any time. This design is particularly suitable for a critical medium (welded gap) and a service medium (sealed gap). An intensive heat transfer takes place in the plate heat exchangers, which can be further increased by turbulence in the flow. A turbulent flow is primarily achieved through the profile on the plates.

Plate heat exchangers can be built very compact and have a very high heat flow density based on their small size , which is why they are used in a wide variety of areas, u. a. in industrial heating, cooling and solar technology .

cleaning

Due to the small distance between the individual plates, the flow is easily hindered or even blocked by dirt . Plate heat exchangers that are blocked by dirt or limescale must be flushed or cleaned in another way.

As a rule, acidic solutions are used for rinsing . In the event of a massive blockage, the screwed plate heat exchangers can be dismantled into their individual parts for cleaning , while the soldered plate heat exchangers have to be replaced. Because of the risk of clogging, plate heat exchangers are not suitable, for example, as cooler service water or for other media containing particles.

In district heating networks , plate heat exchangers are often used to separate the primary circuit and the secondary circuit in the buildings that are supplied with district heating . When milking plate cooler or be tube cooler used to pre-cool the milk before the milk cooling tank is actively cooled down to the storage temperature.

literature

- Plate heat exchanger. In: Helmut Schaefer (Ed.): VDI Energietechnik Lexikon , Half Volume 2, Springer Verlag, Heidelberg / Berlin 1994, ISBN 978-3-642-95749-9 , p. 979

- Plate heat exchanger. In: Siegfried Blickle et al .: Expertise in installation and heating technology , Europa-Lehrmittel, 5th edition from 2014, ISBN 978-3-8085-1527-3 , p. 534

- Manual of building technology , Volume 2, Bundesanzeiger Verlag Cologne, 9th revised edition from 2016, ISBN 978-3-8462-0589-1 , p. L 99-100

- Zierhut: Installation and heating technology: sanitary, heating, air conditioning , 5th edition, Bildungsverlag EINS, Cologne 2015, ISBN 978-3-8242-7417-8 , p. 495

See also

Web links

- Co-current and counter-current principle, gradient, formula for determining the mean logarithmic temperature difference at www.schweizer-fn.de; accessed on September 4, 2018