Electroforming

Electroforming is the primary shaping from the ionized state , whereby metal is electrolytically deposited from an aqueous salt bath. It is mainly used for the production of metallic coatings or for the production of self-supporting metallic workpieces, mostly in high-performance copper or nickel baths .

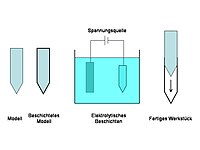

The electroforming system includes an electrolysis tank with electrolyte, anode and cathode as an electrically conductive model on which deposits are made. The connection of an external direct current source is necessary for the ion flow, heating, cooling and circulation.

Procedure: The model (negative form) on which the deposit is made can be made of any metal or plastic, as electrical conductivity can be achieved by treating with conductive varnishes . Layer thicknesses of 0.1 to several millimeters can be achieved, with deposition rates of 25 to 50 µm / h up to 1 mm / h (with newer processes). After the process has been completed, it is necessary to separate the workpiece from the model and possibly rework.

This process can coat very complex geometries. It is particularly suitable for single pieces and prototypes. In addition, there is very good molding accuracy.

Areas of application: including sieves, filters, injection and casting molds in plastics processing, coating of erosion electrodes