Rubber motor

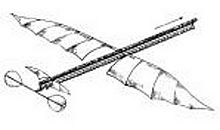

A rubber motor is a simple and light rotary drive with a mechanically elastic energy store . Typically it is in simple wing aircraft - models for temporary driving a propeller used.

history

The rubber motor was developed by the French technician Alphonse Pénaud around 1870 .

Layout and function

- The starting material is highly elastic rubber, which can be stretched to a multiple of its original length, most easily in the form of appropriately large rings or as continuous material from a spool, each in the form of a thread or tape.

- The mounting base of the elongated motor is at least a sufficiently flexurally and torsionally stiff longitudinal rod with a fixed hook at one end and a longitudinally axially rotatable hook at the other end, which is supported here with tensile strength but rotatably and rotatably carries the propeller.

- Individual rubber rings are inserted between these two hooks with a low tensile force or a more orderly winding bundle is stretched from endless material.

- The construction must withstand many times the initial tensile force of the bundle.

- The fixed hook is also fixed with the rod, while the rotatable hook is "pulled" with the propeller in the opposite direction of the later desired direction of rotation. Depending on the desired duration, up to several hundred times.

- The rubber strand is noticeably twisted, but hardly changes its volume. While the strand is twisted as a whole, a longer path is imposed on each individual thread, it stretches along its winding shape but at the same time becomes correspondingly thinner, which means that its tensile force remains constant.

- If the motor is pulled up particularly far, the bundle tends to evade the forced twisting caused by a twist of higher geometry. Threads that were previously close to the axis, which are less tensioned for a long time, are pushed outwards. This visibly creates a new surface structure on the bundle, and the formation of cavities also makes the bundle a little thicker. The "filling level" of the rubber motor can be determined from these phenomena and the somewhat stronger torque on the screw. be assessed.

- As long as the free rotation of the propeller is stopped manually or by a locking lever, the motor remains wound.

- By loosening the lock and letting go of the screw, it rotates quickly against the air resistance and gives the model propulsion until the force of the twisted bundle of rubber threads runs dry.

Aircraft classes

The rubber motor is often used in model aircraft to drive the propeller . Often these flight models are simple children's toys.

However, there are also very sophisticated model airplanes in the international model flight classes F1G (model aircraft with rubber engine (winter cup)) and F1B (Wakefield). Special rubbers are used here, which are normally used as fillers for golf balls. In particular in the model flight class F1B, very complex propeller heads are used, which even enable a torque-dependent blade adjustment. Their rubber motors have a maximum rubber weight of 30 g and are wound with 400 to 500 revolutions.

Thermal brake

So that a circling glider model - launched with or without a rubber motor by hand throw - runs less risk of escaping in good thermals, a so-called thermal brake can be installed, which is also based on a tensioned elastic band.

For long flight times, the radio remote control -free model is trimmed for circling and low sinking or long gliding . With suitable ballasting and adjustment of the rudder and control surfaces.

A rubber band is mounted so that it acts on the horizontal stabilizer so that it can be folded up to a firm stop at the rear, which slows down forward flight and triggers rapid descent. This is prevented for the time being by another rubber ring that fixes the tail unit down in the flight position

A piece of cotton twine, which is soaked in salt and dried, glows in flight at a certain speed and finally burns and cuts the rubber 2, which activates the elastic band 1, which is connected to the second rubber ring and which is connected to the second rubber ring.

The release by glow cord is documented for 1967. Glow cord with 6 mm diameter and minute graduation is also available today.

SIG recommends installing glow cord in a "snuffer tube".

Around 1970 there was a fire in a grain field, triggered by a glow cord, reports a German.

A glow cord device is only about 1 gram in weight.

rubber

Dealer SIG, USA has 1/8 and 3/16 inch (3.2 and 4 mm) wide and 25–475 ft. Long synthetic elastic bands . The largest pack (1/8 "× 475 ft.) Weighs 1 lb.

Lubricating the rubber increases the service life.

See also

Individual evidence

- ↑ The little UHU

- ↑ AMIGO V (Graupner 1966–1989)

- ↑ SIGSH331 Glimmschnur (Sig Shure-Fire DT Fuse, 5 ft.) Accessed December 23, 2019.

- ↑ sigsh331-sig-de-thermalizer-fuse-5

- ↑ The little buddy II-B (GK 126)

- ↑ Streil Cesi (free-flight throwing glider)

- ↑ sig-sport-rubber

- ↑ Sig-rubber-lube