Hang stove

A slope kiln ( Japanese 登 り 窯 , Noborigama , English climbing kiln ) is a Japanese kiln for the production of large quantities of ceramics and porcelain . The furnace is built into the slope of a hill so that the convection of the combustion gases can be used and burned at high temperatures. An amazingly uniform glaze can be achieved with a hanging oven . Slope stoves are mostly built in places where the required raw materials, clay, fuel and plenty of water are available. Hang furnace or noborigama is used as a general term for different types of kilns:

- for traditional multi-chamber kilns ( 連 房 式 登 窯 , Renbōshiki-noborigama , literally: slope kiln with lined up combustion chambers ) and their modern form, the gas or electricity powered roller kiln ("roller hearth kiln")

- for a "tunnel furnace" ( 穴 窯 , Anagama ), which is used for the production of Sue ceramics and

- for the Chinese "dragon kiln" ( Chinese 龍窯 / 龙窑 , Pinyin lóngyáo , Japanese ryūyō )

Overview

In Japan, up to the Kofun period, ceramics were fired in an oxidizing manner by means of a pit fire, similar to open field fires, like Haji ceramics . In the middle of the Kofun period, Sue ceramics brought the method of reducing firing and with it the hanging kiln and the potter's wheel from mainland Korea to Japan. In the 16th century, with the beginning of mass production, thermal efficiency and the size of kilns changed. For this purpose, the combustion chambers were then arranged one behind the other in a row.

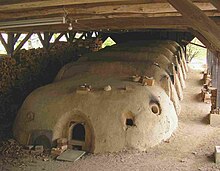

The slope furnace is built into a slope like a pipe that is halved alongside. At the lower end of the pottery furnace is the furnace ( 燃 焼 室 , renshōshitsu ), which is usually fired with wood and is connected to the combustion chamber via a perforated antenna or clay column. In a typical multi-chamber kiln, which looks more like a caterpillar, up to nine further combustion chambers follow, which can be equipped with firing material through side entrances. Flue gas and residual heat are so in a train transmitted to the firing material. The flue gas finally exits again at the upper end of the combustion chamber cascade through a vent. Usually a slope kiln is operated for a firing process at approx. 1300 ° Celsius for a period of 60 hours. The firing temperature is controlled by water cooling and slowly increased to the firing temperature of 1300 degrees within a day. The continuous cooling of the kiln before it is removed from the kiln also requires special attention ( 窯 出 し , kamadashi ).

In Germany, for example, there is a Japanese hanging stove in Krauschwitz .

literature

- Masahiko Satō: や き も の 入門 . Heibonsha, Tokyo 1983, ISBN 978-4-582-61809-9 , pp. 81-84 .

Web links

- 丹波 焼 の 窯 〜 穴 窯 と 登 り 窯 . TANBAYAKI,accessed September 20, 2013(Japanese, with illustrations).

- や き も の の 里 . 石 見 も の づ く り 工房, 2010,accessed September 13, 2013(Japanese).

Individual evidence

- ↑ 登 り 窯 . In: デ ジ タ ル 版 日本人 名 大 辞典 + Plus at kotobank.jp. Retrieved September 20, 2013 (Japanese).

- ↑ Gran Pottery Overview. (No longer available online.) Kulturpixel.de, archived from the original on September 23, 2013 ; Retrieved September 21, 2013 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.