Heating and cooling rollers

As a rule, heating and cooling rollers are used to supply or withdraw thermal energy from a web of material in order to be able to carry out certain work steps (such as gluing material streams or the like). The heating and cooling rollers are therefore often traversed by a temperature control medium (e.g. a heating or cooling liquid ) and thus generate the desired temperature on the roller surface . Depending on the process-related requirements for temperature constancy (e.g. with varying production speeds), the turning angle of the heating and cooling rollers to control the supply or return of energy on the web can be adjusted manually or automatically by means of web temperature regulation.

Areas of application

- Printing industry , especially in the areas ...

- Plastic and textile industry

- food industry

Variations

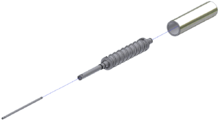

In addition to diverse designs of the most varied of surface coatings and base body materials, cooling rollers and heating rollers differ essentially in the arrangement of the inlet and outlet of the temperature control medium and the arrangement of the guide spirals (linear or degressive).

Individual evidence

- ↑ a b Edwin Kiel: Drive solutions: Mechatronics for production and logistics . Springer-Verlag, 2007, ISBN 978-3-540-73427-7 ( google.com [accessed July 7, 2016]).

- ↑ Technical rolls, chill rolls, heating rolls. In: www.bolz-gmbh.de. Retrieved July 7, 2016 .