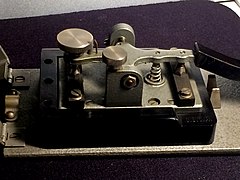

Junker morse key MT

The Junker Morsetaste MT (also called “Junker-Button”) is one of the longest almost unchanged produced Morse code keys worldwide - it was produced from 1931 to 2014.

use

The button is mainly used in German-speaking countries and was part of the standard of authorities and institutions ( Bundeswehr , Norddeich Radio , DGzRS , DEBEG radio equipment for the navy and merchant navy, etc.). It was copied for a long time by the manufacturer association for radio and telecommunications technology in the GDR . In the amateur radio sector , the button is still in demand and in use.

nature

From 1926 the former sea captain Joseph Junker built his hand key. It was patented in 1931 and produced until 2014 by the company Joseph Junker GmbH, which he founded, as a precision Morse code key type MT in an almost unchanged design. Special features of the button are the adjustable spring pressure of the transmission arm as well as the adjustable distance between the switching contacts ("stroke") of the manual button .

The patent specification from 1931 argues with the need to adapt the button to the different "hand gravity" of the radio operator without interrupting radio operations. It was therefore assumed that the radio operators would switch to the same key on the fly in order to ensure continuous operation without any signs of fatigue. The individual setting could be quickly restored using markings on the adjusting screws.

The subtleties

casing

The button is built on a sheet steel sole measuring 80 × 195 mm and 5 mm thick. The weight of the complete button is approx. 1 kg. There are three rubber feet on the underside to ensure good stability and slip resistance. The protective cover was made of cast aluminum until the mid-1960s, later made of sheet steel and shields the interior of the button well against HF effects. The lid is kept closed with a locking spring under the key arm so that the key can be grasped and moved on the lid without problems. For better grip, there are three corrugations on both sides of the lid so that you do not slip unintentionally when gripping.

mechanics

The mechanics are precision mechanics. The trigger arm has a cross shape and, like the key base, is made of solid cast aluminum, with the hard plastic ( Bakelite ) button pressed onto the actuating end . All work and break contacts are fastened with screw connections and can therefore be replaced. The bearing arm is fastened with a push-through axle in the mounting of the lower plate. This axis can be adjusted without play and yet smoothly. In order to ensure good contact, the transmission arm is electrically connected to the lower part by a bronze spring. A knurled screw for adjusting the key travel is located at the rear end of the transmitter arm; in the commercial version with a ball catch on the underside and a pointer to mark a setting. A device for adjusting the key pressure is built into the lower part, which is operated with a knurled screw. The stroke can be set very finely due to the precise storage and adjustment options, so that even the highest transfer speeds can be achieved cleanly.

Electrics

The contacts were made of silver until the mid-1960s and later of stainless steel. All three contacts of the button are electrically connected to connections on the rear. The button can either be used as a toggle switch or, as is common practice, as a simple make contact. The rear (rest) contact remains closed until the button is pressed. The normally closed contact opens shortly before the normally open contact closes, which can be used very easily and safely for an automatic send / receive switchover. You could hear between the characters like this (QSK). For interference suppression purposes and to protect the contacts from electrical erosion , a spark extinguishing circuit of 100 ohms with 0.1 µF in series is installed parallel to the normally open contact and an air coil of 25 µH in series with the contact.

Web links

- Christine Pfalz: Junker Morse code - world product from Bad Honnef. In: Honnef today. July 31, 2018, accessed November 15, 2019 .

- City history: Junker Morsetaste MT for the city archive Bad Honnef. In: General Anzeiger Bonn. July 31, 2018, accessed November 15, 2019 .

- H. Busch: The Morse code Junker MT 2016, accessed on November 22, 2019 .

- SFK Bremen: Homepage of the Marine Radio Comradeship Bremen. Retrieved November 26, 2019 .

- The Junker key in the Navy. In: Der-Fernmelder.de. Retrieved December 9, 2019 .

Marine radio stations with Junker key

- Radio station DLAH, Dampfer Adolf Binder 1941. Retrieved on November 25, 2019 .

- DLAM radio station, MS Adolf Vinnen 1955. Retrieved November 25, 2019 .

- On-board radio station DKMY, MS Christiane Oldendorff 1962. Retrieved on November 25, 2019 .

- On-board radio station DGDC, MS Düsseldorf Express 1977. Retrieved on November 25, 2019 .

- Radio station DNGD, MS Dorothea Schulte 1981. Retrieved on November 25, 2019 .

Individual evidence

- ↑ DK5KE: Information about the Junker key. In: qsl.net. Retrieved November 14, 2019 .

- ↑ Company research: The Joseph Junker company was liquidated in 2014. In: Northdata.de. Retrieved December 7, 2019 .

- ↑ onboard radio station DAQM, MS Cap Valiente 1959 DEBEG equipment and Junker button. Retrieved November 25, 2019 .

- ↑ DL3BN: amateur radio station with Junker button. Retrieved November 25, 2019 .

- ↑ Reich patent No. 613176 for the Morse code from Joseph Junker dated November 11, 1931. Archived from the original on March 4, 2016 ; accessed on November 14, 2019 .

- ↑ a b brochure of Joseph Junker GmbH: Precision Morse code key type MT In: DL1HQE.de. April 22, 2007. Retrieved November 22, 2019 .