Air core coil

Air- core coils are inductive components without a soft magnetic core and have relatively small inductances compared to coils with a soft magnetic core . A special design, which is formed by enamelled copper wire and holds its shape by gluing the enamel insulation, is also known as a baked enamel coil .

Due to the lack of a magnetic core, the magnetization characteristic is linear and the coil, in contrast to coils with a magnetic core, has no magnetic saturation as an essential property . Since the magnetic flux cannot be directed in a targeted manner without a magnetic core , the magnetic leakage flux is high with air-core coils .

The name air-core coil comes from the core material air, but for manufacturing reasons, the coil is usually not self-supporting , but wound on a non-magnetic core that only mechanically fixes the structure. The calculation of the magnetic field and the inductance of cylindrical air coils is described under Cylinder coil .

construction

Air coils are built in different shapes. Cylinder coils in which the wire is wound in a helical shape are very often used . Smaller air coils can be made self-supporting using stiff wire.

Circular ring coils , also known as toroidal coils or Rogowski coils , are complex to manufacture because the entire wire has to be passed through the opening of the torus again and again during winding. In the case of the annulus coil, the magnetic field lines predominantly run inside the coil. For this reason, their field couples relatively little unintentionally with the environment.

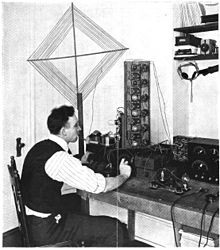

In the early days of electronics, there was a lot of experimentation with designs, in particular to reduce parasitic capacitances through special winding shapes: honeycomb, basket bottom and cross-wound coils (the latter are also available in versions with a core). In most cases, a non-magnetic winding core is required.

Flat coils can have a spiral or rectangular shape. They can also be produced as a conductor track on printed circuit boards ( planar coils, planar transformers ). However, only relatively small inductances can be produced in this way. In addition, they couple relatively strongly with the environment, i. In other words, they unintentionally scatter their field into neighboring components and, conversely, are also influenced by them.

In order to produce self-supporting coils, so-called baked enamel wire is used, which has an outer layer whose melting point is lower than the melting point of the insulation. After the coil has been wound, the turns of the coil are superficially bonded to one another (glued) by heating, usually by increasing the flow of current through them.

A special design of the air-core coil which does not consist of copper wire, but of thin insulated copper sheet or foil, the copper foil coil (English copper foil coil, CFC).

Air coils are easy to cool by blowing on them with a stream of air - unless a wound body / carrier body obstructs the air stream.

Applications

Communications engineering

Air-core coils are used because of the small inductance values, for example in the high-frequency range, for example. B. as a choke coil , in filters or in resonant circuits . The Helmholtz coil is used to generate defined magnetic fields . Only air-core coils are used in transmission systems as well. Air coils with a particularly large diameter are used as loop antennas . Typical inductance values for small air-core coils are in the range of 100 nH to 100 µH, large loop antennas reach 10,000 µH.

Another area of application for air coils are passive loudspeaker crossovers for reusable loudspeaker boxes. The required inductances are between 0.1 and 6.8 mH. The problem is the large number of air-core coils required for these comparatively high inductances, which quickly leads to an undesirably high DC resistance with small wire cross-sections. However, these high inductances are particularly necessary in low-pass filters for woofers.

In this area, a low ohmic resistance between amplifier and loudspeaker is desirable in order to obtain high attenuation. For this reason, open ferrite cores are used as the coil core material in many boxes. The non-linear distortions that occur due to hysteresis and magnetic non-linearity or magnetic saturation are negligible with suitable dimensioning. The picture on the right shows the voltage and sinusoidal current curve at an air core coil, the ohmic resistance of which is similar to its inductive resistance, which is relatively small at only 50 Hz.

Electrical Power Engineering

Applications of air coils in electrical energy technology include the short-circuit limiting reactors and air coils used in power plants and substations to influence reactive power . Other examples with a wide range of applications are air-core coils with variable or adjustable inductance. When used as a short-circuit limiting choke, the low inductance is a disadvantage, but even with high short-circuit currents, there is no desire for saturation and thus a loss of the current-limiting effect. This property can only be achieved by air-core coils whose inductance is independent of the current flowing through them. In the case of larger air chokes in the range of 100 Mvar and above, there must be no reinforced concrete with electrically closed loops in the reinforcing steel near the coil, such as the foundation . Due to the leakage flux, the "electrical short-circuit windings" of the reinforcing steel would otherwise produce induced currents, which would lead to inadmissible heating of the reinforced concrete.

Another application are ironless armatures of DC motors and voice coils of dynamic loudspeakers and microphones , which are characterized by their low mass. In these applications, a self-supporting coil moves in the air gap of a permanent magnet .

Inductance

Optimal cylinder coil, shortest wire length

The shortest wire length of a coil results from winding length = winding width = inner radius (Shawcross and Wells, 1915; Brooks, 1931). The following approximation formula is used for the calculation:

where is the inductance , the magnetic field constant , the number of turns, the diameter of the coil, the wire cross-section and the copper fill factor.

Pink & Grover give (1912, p. 136) the following formula for a multi-layer coil with a rectangular winding cross-section:

This is the mean radius of the winding and the “geometric mean distance” introduced by Maxwell. For rectangular cross-sections with (winding height , winding length ) the following applies to a good approximation

swell

- ↑ http://www.directindustry.de/prod/siemens-ps-power-transmission-solutions/variable-drosselspulen-32878-723777.html

- ↑ http://www.maxonmotor.de/produkt_uebersicht_ch_deu_details_maxon_dc_motor_ch_deu.html

- ↑ G. Schenke, Bauelemente der Elektrotechnik 2008, p. 37 ( Memento of the original from September 24, 2015 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ Kohlrausch, Niederfrequenz, p. 633ff

![{\ displaystyle L = \ mu _ {0} N ^ {2} r \ left [\ left (1 + {\ frac {3a ^ {2}} {16r ^ {2}}} \ right) \ ln {\ frac {8r} {a}} - \ left (2 + {\ frac {a ^ {2}} {16r ^ {2}}} \ right) \ right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/26d6945b9edd16a7dfc43bcf7e160e3cf422d0c7)