Cooling through drying and evaporation

Under cooling by drying and evaporation means the cooling of the air by moistening with water after prior drying and recooling.

Explanation

This cooling process works without refrigerants and compressors and is mainly used to cool the supply air in ventilation systems. Sometimes it is also referred to as DCS (Desiccant Cooling Systems) or DEC (Desiccative and Evaporative Cooling).

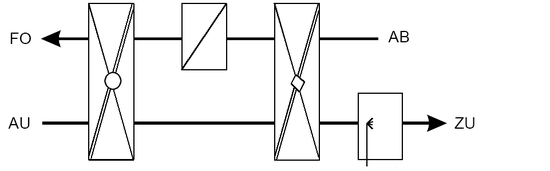

The picture shows a block diagram of such a system.

Thermodynamic principle

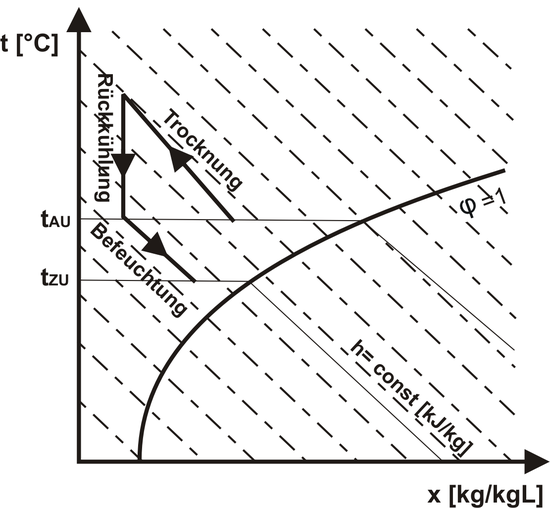

- Warm outside air is sucked in and dehumidified in a rotary dehumidifier. This increases the enthalpy (thus the temperature) and the water content decreases.

- This air is recooled in a cross-flow heat exchanger. The outside air transfers the heat to the exhaust air.

- The last step is to humidify the air . This lowers the temperature. The supply air is blown into the room.

- A heater in the exhaust air stream heats the exhaust air so that it can absorb moisture in the rotary dehumidifier. This regenerates the rotor.

In order to be able to operate this process sensibly from an ecological and economic point of view, the energy supplied to the exhaust air flow must be as inexpensive as possible. Suitable is e.g. B. solar energy, district heating or waste heat from a CHP.

The picture shows the basic course in the hx diagram (not to scale).

With the help of the exhaust air, cooling can also be carried out by means of evaporative cooling (specifically by misting water), since the evaporative cooling cools the supply air by means of heat recovery . This has the advantage that the water does not come into contact with the supply air and therefore the heat recovery does not have to meet any hygienic requirements. But it has the disadvantage of water consumption (including waste water charges).

literature

- Recknagel -Sprenger-Schramek, pocket book for heating air conditioning technology , ISBN 3-486-26214-9

Web links

- An Overview of Open-Cycle Desiccant Cooling Systems and Materials a PDF file of the NATIONAL RENEWABLE ENERGY LABORATOR (English)