Ceramic ground resistance

A ceramic ground resistor is one type of electrical resistor .

General

Ceramic ground resistors are the "successors" of the carbon ground resistors . In the process, grains of coal were no longer mixed with ceramics or possibly just some kind of clay, but ground metal is almost exclusively mixed with ceramics. This mass avoided the bad properties of the earlier carbon mass resistors such as large manufacturing tolerances . The material is u. a. also known as cermet . By definition, cermets are considered non-conductors, but resistances can be implemented with them.

Since the ceramic ground resistor also has almost no (parasitic) inductance, resistors suitable for high frequencies and with greater stability than the carbon ground resistors are possible. In the English-speaking world, these resistors are called English ceramic composition resistors . The term "ceramic mass" is slightly misleading, since this mass is a mixture or composition or composition ( English composition ) of several materials.

Ceramic mass resistors are not to be confused with the so-called "cement resistors", which are encased as a special form of wire resistance in a sand-filled ceramic body (similar to some electrical fuses ) and thus have poorer high-frequency properties .

construction

Resistance material

The resistance-determining material consists of three components:

- Finely ground metal

- Finely ground ceramic (often aluminum oxide, Al 2 O 3 )

- Plastic or binding agent

The plastic or the binding agent are often used for a more even distribution of metal and ceramic within the initially powder-like material.

Depending on the desired resistance value or the maximum planned power loss of the resistance body, this mass is pressed into certain shapes in different mixing ratios. This results in a more homogeneous internal structure (measured by the structure of the carbon mass resistance) of conductive metal and non-conductive ceramic grains of relatively equal size, which touch with more equal (equivalent) surface sizes.

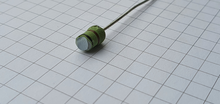

Housing and contact

The mostly cylindrical resistor blanks are surrounded by an insulating cover made of pure ceramic. The contact is made through lead wires baked into the blank. Depending on the geometry, the resistors are printed or provided with colored rings to encode the value of the resistor.

The resistance material is very hard and therefore brittle, but offers high mechanical strength. The sinterability allows almost any shape of the resistors. They are available in a wide variety of geometries, e.g. B. as tubes, rods or as discs.

Parameters

Resistance value

Ceramic ground resistors are available in all common values from the ohm to the megaohm range in accordance with the E series E6, E12 and E24.

Tolerances

Ceramic mass resistors are offered with tolerances of 20%, 10% and 5%.

stability

The stability of the resistance value is higher than that of the carbon mass resistors. In most cases, however, they are also not suitable for precision applications. Additional tolerances can be added to the above delivery tolerance of up to 20%. A value of 5% per 1000 hours of operating time is often given as the aging value. The temperature can be up to 250 ° C. The temperature coefficient is negative and can be up to −1600 ppm . With a temperature change of +100 K, this means a change in resistance of −16% (for comparison: today's resistances are usually in the range of ± 50 ppm to ± 100 ppm).

Noise

The noise of ceramic ground resistors is lower than that of the carbon ground resistors due to the more stable internal arrangement of conductive material grains.

Linearity

Depending on the voltage across the resistor (approx. 100 V or more), disruptive non-linearities of up to 7.5% per kV and cm occur.

Pulse resilience

The pulse resilience of ceramic mass resistors is enormous. Due to the extraordinarily good thermal conductivity of the ceramic mass and the fact that this is virtually solid material, there is hardly any local overheating within the component. This property allows the resistor to absorb the highest pulse energies. The available cross section of the resistor body is decisive here. Example values for maximum energy input for axial resistances from data sheets are 23 kW / sec / cm².

Designs

There are currently no known standardized designs. The dimensions were and are determined by each manufacturer depending on the planned maximum permissible power loss and were (or are) therefore at most similar.

Areas of application

The above-mentioned pulse load capacity ensures that there are some areas of application for these resistors:

- Current limiting circuits

- (Discharge) protection circuits

- High voltage power supplies

Voices and opinions from practice

Among electronics enthusiasts and hobbyists, ceramic resistors are often "workhorses" when it comes to converting power thermally. This means that intrinsically safe protective circuits can be implemented that do not fail in the event of a fault.

When restoring older audio technology, these resistors can be a very good, much less noisy alternative to carbon-ground resistors.

Web links

- http://blog.hilltech.com/?p=249

- https://www.engineersgarage.com/tutorials/articles-basic-electronics-fixed-resistors-carbon-composition-ceramic-carbon-film-metal-film-metal-oxide-cermet/

- http://usresistor.com/index.php/materials/ceramic-resistors