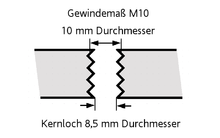

Core hole

A core hole is a hole in which an internal thread is cut.

function

The diameter of the core hole (bore) is minimally smaller than the later internal diameter of the thread. Through the cutting process with a tap , the material is peeled out during thread cutting and the resulting burr is shaped into thread peaks. With thread forming , the material is formed into the thread flank. A core hole with a diameter of 6.8 mm is required for an M8 thread in structural steels.

However, if the internal thread is not produced with a tap , but with a lathe chisel or a milling cutter , then the permissible core hole diameter is identical to the minimum or smallest dimension of the internal diameter of the thread to be produced.

Dimensioning

| thread | pitch | Core hole ⌀ |

|---|---|---|

| M12 | x 1.75 | 10.2 |

| M10 | x1.5 | 8.5 |

| M8 | x1.25 | 6.8 |

| M6 | x1 | 5.0 |

| M5 | x0.8 | 4.2 |

| M4 | x0.7 | 3.3 |

| M3 | x0.5 | 2.5 |

It is common practice for dimensioning to subtract the thread pitch from the nominal thread diameter.

Which core diameter has to be drilled for which thread can be taken from the corresponding DIN or ISO tables, or must be adapted to the specific task. The metric ISO standard thread is the most widespread in Germany . A table of the core hole diameters can be found in the corresponding article.

Since the drill diameters for the different thread sizes often have "crooked" dimensions, for example for M4 = 3.3 mm, M5 = 4.2 mm or M8 = 6.8 mm, the corresponding drills are sometimes also referred to as core hole drills.