Koker

The coker system (simply called coker or coker ) is a process engineering system in a petroleum refinery , in which residues of various origins are converted into lighter hydrocarbons under a lack of oxygen. The long-chain are hydrocarbons thermally at about 500 ° C into shorter chains cracked . In addition, considerable amounts of coke ( carbon), which - depending on the type of coke oven - is sold as a product or gasified in the process to produce what is known as low-calorific gas. Compared to other cracking processes, coker products have a higher proportion of unsaturated hydrocarbons. In all coker systems, the product stream is separated in a downstream rectification . Coker make heavy oil combustion superfluous. There are 3 process variants: Delayed Coker, Fluid Coker and Flexicoker.

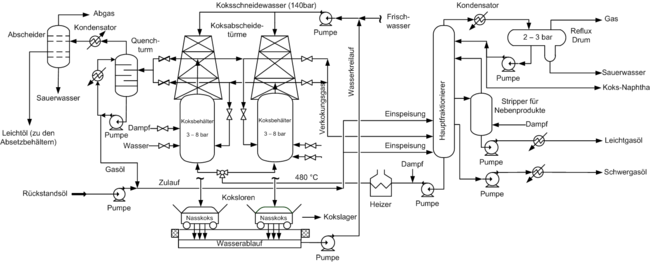

Delayed coking

With delayed coking , the residual oil is first passed into the main fractionator of the coker plant, where it can be used. a. serves as a washing medium for the product flow from the coke towers - the actual reaction vessels - (heavy parts from the active coke tower are thus fed back into the process, recycled). The rectification residue is then heated to around 500 ° C and then sprayed into the active coking chamber, where it is converted into petroleum coke , liquid and gaseous hydrocarbons. In the other - inactive coke chamber - the petroleum coke is hardened or cooled with steam and water and then cut out with a water jet (water pressure of up to 350 bar). The petroleum coke , also called green coke, is used after drying as fuel in power plants or as an additive in the steel industry. Depending on the quality, the petroleum coke can also be freed of residual volatile hydrocarbons by calcination at approx. 1200 ° C and is then used to manufacture anode material for the aluminum or steel industry. The use depends on the quality parameters of the coke. Coke with a high sulfur or metal content cannot be used as an anode material in the aluminum industry. In the steel industry, however, the requirements are not so high, since high vanadium or nickel contents are even desirable, so that this sulfur-containing coke can be used as an anode material without being purified.

Fluid coking

The fluid coking works similarly to the fluid catalytic cracking . The coke that is produced as a fine powder serves as a “catalyst”. In the reactor, the feed reacts on the coke particles, which form a fluidized bed through the introduction of steam. The light products are drawn off upwards, the coke dust runs into a so-called Coke Heater (called regenerator at the FCC). There the coke is partly burned with air (this generates the required process heat), part is returned to the reactor and part is pressed and sold after calcination. The advantage of this process management is that - compared to delayed coking - the dangerous cutting of the petroleum coke from the inactive coke tower is no longer necessary. A fluid coker is, however, considerably more expensive and more complex to regulate.

Flexicoking

Flexicoking (Exxon patent) is an improved but more complex version of fluid coking. The coke is not burned in the heater, but heated by the hot exhaust gases (low-calorific synthesis gas ) from a gasifier. The gasifier uses the excess coke that is discharged during fluid coking. Gasification takes place through partial oxidation with air and steam injection. This process produces only very small amounts of coke (a small part always has to be discharged to remove the metals), but mainly hydrocarbons that can be distilled in the atmosphere, such as low-calorific fuel gas. Sulfur can be removed from the main products by desulfurization ( hydrodesulfurization ) followed by amine scrubbing .