Column (process engineering)

A column is a process engineering apparatus in the form of a hollow, slender column with internals which are required due to the intended use or the operating conditions. As a rule, it is used to separate mixtures of substances using various thermal processes. For this purpose, physical properties and states of equilibrium between different phases are used.

Separation processes in which columns are used in process engineering are for example

principle

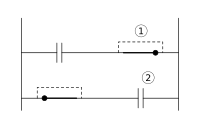

In a column two are phases in countercurrent directly brought into contact or a phase on a solid phase (eg. As an adsorbent ) moves. Internals in the column serve to increase mass transfer and energy exchange between the phases or (as in extraction) to avoid backmixing. A column can be described as an interconnection of several stages that are back-mixed, with both phases in equilibrium.