Condensation drying

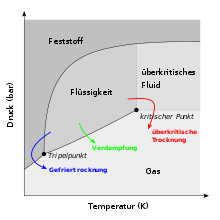

Phase diagram: The condensation drying runs backwards along the green arrow.

Note : The diagram neglects the irrelevant anomaly of the water .

Note : The diagram neglects the irrelevant anomaly of the water .

The condensation drying is a Luftentfeuchtungsverfahren , which is often used in the industrial and private sectors, for example in the dryer or classic Bautrockner . For this purpose, humid air is guided by fans over cooling fins / fins, the temperature of which is below the dew point of the air. Thereby condenses the water and collects as condensation on the cold surface, which is collected in a separate container. The cooled and dehumidified air is then heated and released as dry air.

Application area

The area of application of condensation dryers depends on the temperature and humidity of the work area:

- Temperature: approx. 5 ° C to 30 ° C

- Humidity: approx. 40% to 99% relative humidity

advantages

- No great danger for other building structures, as the air humidity is reduced continuously and not suddenly.

- Can be carried out without great technical effort

- High efficiency with relatively low energy consumption. The latent energy of the air humidity is converted into heat energy (the air is thus heated).

- There is no need for a window or the like to discharge the moist air. The condensate can be drained through a hose or into a container.

- Devices with automatic defrosting switch off automatically when the fill level is reached.

- Comparatively low acquisition costs in contrast to adsorption dryers

disadvantage

- Limited area of use (depending on temperature and humidity)

- If the setpoint is below 40% relative humidity, the method does not work efficiently in a simple configuration of the cooler as an open system if the ambient air is only slightly above this.

- It is no longer economical to use at temperatures below +6 ° C, as only a small amount of condensation can be removed.

- At temperatures above +33 ° C, overheating of the compressor must be expected.