Phase mask (transmission grating)

A phase mask is a special type of optical transmission grating . It usually consists of quartz glass into which linear depressions have been etched periodically at a defined distance.

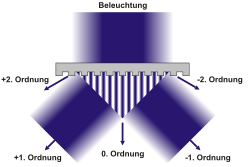

If this structure is illuminated with coherent light, the light is diffracted , as is usual with a grating : the light is deflected in several directions. If the illumination takes place with a light beam that has a certain diameter, the diffracted light beams overlap in an area under the phase mask. As they spread out in different directions, there is a striped interference pattern .

Typical configurations

"+ 1 / -1" configuration

The simplest option is lighting perpendicular to the surface of the mask. To a large extent, the light is deflected into the orders +1 and −1. Thanks to a special manufacturing design, the zeroth order is largely suppressed, as it has a disruptive effect here. Higher orders can also occur. The diffraction angle of the first order (measured perpendicular to the mask surface) is calculated as

- .

Here are the wavelength of the light used and the line spacing of the grating.

The period of the resulting stripe pattern is half the line spacing of the grating.

"0 / -1" configuration

In this configuration, the mask is illuminated at an angle. In addition to the non-diffracted beam, the first order occurs on one side. If the light wavelength is greater than the line spacing , then no second order can exist, as the diffraction angle would be greater than 90 °. In this configuration, disruptive orders can be avoided. For this, the mask must be illuminated at a specified angle of incidence, which can be calculated

- .

The period of the resulting stripe pattern is here equal to the line spacing of the grating.

Applications

The resulting stripe pattern allows a phase mask to be used for the photolithographic production of periodic structures. Instead of using a “mechanical” mask, in which the areas to be illuminated are defined by openings in the mask and the rest remains shaded, this “optical” mask uses an interference effect to periodically illuminate it.

A common application is the manufacture of fiber Bragg gratings .