Wheel nut indicator

Wheel nut indicators are used to secure the wheels of vehicles, primarily trucks , in order to prevent accidents caused by loosening the wheel nuts . They are easy to assemble without tools. Every driver of a truck must make sure that the wheels and tires are in a safe condition before starting a journey; this is what professional associations require in their accident prevention regulations . However, time pressure and lack of knowledge often mean that these tests are not carried out. According to the results of a study carried out in Great Britain , almost a third of all drivers do not check the wheel nuts before setting off. In a newsletter from the German Association for the Tire Trade (BRV) from 2012, it says on the relevance of the safety aspect: "The advantages (...) are obvious: For the fleet manager, they mean a considerable simplification and shortening of the inspection tours as well as an improvement in the Maintenance and safety of the fleet. All in all, they significantly increase road safety for all road users, whether drivers, pedestrians or fleet owners. ”Wheel nut indicators are available in numerous variants and wrench sizes. Both the driver and control authorities such as the police can see at a glance whether the wheel nuts are secured.

history

In 1990, Mike Marczynski, who was responsible for a commercial vehicle fleet, developed the locking system for wheel nuts and initially marketed it in Great Britain under the brand name Checkpoint . His invention is now available in more than 90 countries on 6 continents. The product has also established itself in Germany, and more and more trucks with the safety system can be seen on the highways. The original locking product for loose wheel nuts, the checkpoint , has been supplemented by other products such as Dustite and Dustite LR , which combine the function of a wheel nut indicator with a dust cap and thus provide additional corrosion protection for bolts and nuts.

Further developments followed: Wheel overheating due to problems with the brakes and / or the ball bearings is a common problem for vehicle operators. To solve this problem and to improve the safety of vehicles using the products, indicators have been developed that are equipped with an overheating indicator are. For this purpose, specific polymers were used that first deform at elevated temperatures and then melt. Especially for the needs of ambulances , where the driving and braking behavior is significantly different, wheel nut indicators made of a high temperature material have been developed, whose melting point of 165 ° C is a lot higher than that of the standard variant (melting point around 125 ° C) .

Legal basis

BGV D29 § 36 Condition control - vehicle defects:

The BGV D 29 is the accident prevention regulation "Vehicles" of the employers' liability insurance association (previous VBG 12). Here it says: “(1) The vehicle driver must check the effectiveness of the actuation and safety devices before the start of each work shift and monitor the condition of the vehicle for any obvious defects during the work shift. (2) The vehicle driver must notify the responsible supervisor of any deficiencies found and, if the vehicle driver changes, also the person replacing the vehicle. In the event of defects that endanger operational safety, the vehicle driver must cease operations. "

as well as: DGUV principle 314-002 (formerly BGG 915) point 2.2: Control of vehicles by drivers:

Here it says under point 2 "Check points for the vehicle inspection before the start of the work shift":

2.2 Rims, tires and suspension

- Rims / wheel disks are without any visible damage.

- All wheel nuts / bolts are present, undamaged and are tight (visual inspection).

- [...]

Danger in road traffic from loose wheel nuts

Every loosening wheel nut harbors a potential risk of an incident (= wheel loosing / wheel loss):

- without damage to property or personal injury

- with property damage, but without personal injury

- with property damage and personal injury

- with property damage, personal injury or death

Probability of loosening wheel nuts:

The following table shows the probability of an "incident" due to loosening wheel nuts for companies (e.g. freight forwarders) taking into account the number of vehicles and the number of hours of use per day or week (e.g. during shift work).

| Number of vehicles (pieces) | Number of hours / day in use | Number of days per week in use | Number of incidents (extrapolation) |

|---|---|---|---|

| 10 | 8th | Mon-Fri (5 days) | 1 incident / year |

| 10 | 24 | Mon-Fri (5 days) | 3 incidents / year |

| 10 | 24 | 7 days | 5 incidents / year |

| 100 | 24 | 7 days | 50 incidents / year = 1 incident / week |

| 1000 | 24 | 7 days | 500 incidents / year = 10 incidents / week> 1 incident / day |

Further influencing factors:

- changing drivers on a vehicle

- Duration of the journey (long distance, commuting, etc.)

- own workshop

- regular checks (e.g. by a workshop)

- Driving behavior

- Application area (e.g. construction sites, motorway)

Extracts of the results of the study carried out in Great Britain "Heavy Vehicle Wheel Detachment: Frequency of occurrence, current best practice and potential solutions", which is based on numerous studies in the United Kingdom (UK):

| Incidents and Consequences: | Average frequency per year |

|---|---|

| Problems with loose and missing wheel nuts overall (including damaged wheel nuts and damaged wheel bolts) | Between 7,500 and 11,000 |

| Wheel loss (total number of incidents) | Between 150 and 400 |

| Property damage due to wheel loss | Between 50 and 134 |

| Personal injury / injuries due to wheel loss | Between 10 and 27 |

| Deaths due to wheel loss | Between 3 and 7 |

The number of incidents that are not properly assigned to the cause of "loose wheel nuts" or are not known and therefore do not appear in the official statistics will most likely increase the aforementioned numbers.

As part of this study, the drivers were also questioned representative.

The results are:

- only 76% of drivers carry out their checks on a daily basis

- 68% of the drivers check the wheel nuts during their inspection

- 2% of drivers never do routine checks

- 33% of drivers did not know how often the wheel nuts were checked

- 50% of drivers do not retighten the wheel nuts after changing tires

Working method

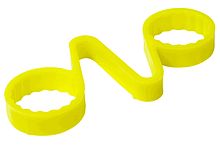

Two Checkpoint / Dustite / Dustite LR are attached to two adjacent wheel nuts in such a way that the respective indicator tips point to one another (see figure above). If a wheel nut loosens, the pointer moves according to the movement of the wheel nut, ie the tips no longer point to one another. The wheel nut indicators not only allow the wheels to be checked quickly and efficiently by the drivers, but also by the control authorities. In addition, the inspection can be easily documented with a photo (including the date).

Product descriptions

The wheel nut safety products can be divided into three main categories: indicators, indicators with position holder function and position holder.

Areas of application

Basically, the wheel nut indicators are designed for all types of commercial vehicles. Due to the different sizes, they can be used from station wagons to heavy-duty trailers:

- truck

- Travel buses / buses or public transport

- Emergency services (special high temperature material)

- Police and control authorities

- Vehicles transporting dangerous goods

- Agricultural vehicles, tractors

- Off-road vehicles and SUVs

- Construction site vehicles

However, wheel nut indicators cannot only be used on vehicles, but are also used worldwide in the industrial sector, for example

- on pipelines in the sea

- on windmills

- on assembly lines

- on cranes

Wheel nut indicators are not only used for the safety and control of vehicles, but also of all possible types of machines, devices and systems that are exposed to high loads, wear and tear and vibration and are in constant use.

Individual evidence

- ↑ a b BGV D29 § 36 Condition control - vehicle defects: BGV D 29 is the accident prevention regulation "Vehicles" of the employers' liability insurance association (previous VBG 12)

- ↑ a b BGG 915 point 2.2: Inspection of vehicles by drivers: BGG 915 concerns the BG principles "Inspection of vehicles by drivers" (BG = professional association) (previous ZH1 / 282.1)

- ↑ a b Heavy Vehicle Wheel Detachment: Frequency of occurrence, current best practice and potential solutions, carried out by TRL Limited, on behalf of Transport Technology + Standards (TTS) 6, Department for Transport (DFT), S0535 / V6

- ↑ Newsletter of the Federal Association of Tire Trade and Vulcanization Crafts e. V. Trends & Facts from 2012

- ↑ DGUV 314-002. Retrieved January 16, 2019 .

- ↑ TS Society for Transport and Security Systems, Gevelsberg