Jumping stones

Stone jumping is a technical term for the uneven influx of steam in steam locomotives with Heusinger control and hanging iron , primarily when reversing.

The cause of the uneven steam inflow is the peculiarity of the movement combinations of the rocker arm running in the rocker arm, i.e. the pivot point of the slide pushrod in the rocker arm, especially when reversing and fully configured control.

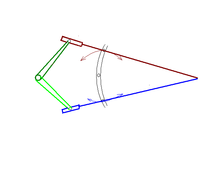

When a steam locomotive travels forward with an internal flow, the rocker block is below the pivot point of the rocker arm, as is the upper pivot point of the hanging iron. Both pivot points, the rocker and the linkage of the hanging iron, oscillate harmoniously around pivot points that are only shifted parallel. The steam flow into the steam engine is even (blue arrows). When reversing, the positions of the pivot points change. The rocker (pivot point of the slide pusher rod / rocker arm) swings around the pivot point of the rocker arm, and the linkage (pivot point of the hanging iron / slide pusher rod) swings around the now elevated pivot point of the raising lever (brown arrows). As can be seen from the diagram opposite, the movements are in opposite directions. As a result, the slide pushrod also moves slightly up and down in the rocker. This movement is called jumping stones . However, since the deflection of the slide pushrod from the pivot point of the rocker controls the size of the steam inflow, it becomes uneven. In the case of locomotives that often had to drive backwards ( tank locomotives ), stone jumping could be reduced by installing a Kuhn loop .