Headset (bicycle)

In a bicycle, the headset is the bearing that rotates the steerer tube of the bicycle fork in the head tube of the bicycle frame. The headset consists of two roller bearings , the upper and the lower tax bearing. The steering bearings transfer the weight of the frame and rider to the fork crown and thus to the front wheel. Furthermore, the control bearings guide the forces generated during braking into the frame and enable the steering movements that the physical principles of the dynamics of cycling require.

Size designations and standardization

The nominal size of the headset is the size of the steerer tube , which is the outer diameter in inches at the top of the steerer tube. The four occurring nominal sizes (1 ″, 1⅛ ″, 1¼ ″, 1½ ″) do not, however, fully specify the tax rate. There are different construction heights for each size (height of the bearing visible from the outside when installed), on which the length of the steerer tube depends. Other specific dimensions are the outside diameter, offset and the dimensions of any chamfers that may be present. With the “tapered” fork stem, the lower control bearing is larger. With the "reduced tax rate", the external dimensions of the tax bearings are designed in a larger nominal size.

There is no international standardization for the steerer tube and head tube and therefore no standardization for the headset. Nevertheless, certain standards have developed, from which there may be deviations. In particular with historical versions, which practically only affect the one-inch steerer tube (25.4 mm), there are various incompatible variants. Some examples are given in the article bicycle fork, chapter steerer tube.

Systems

There are two different types of headset : the threaded headset (for the steerer tube with external thread and stem with internal clamp) and the ahead headset (for the threadless steerer tube and stem with external clamp ). The only difference between the two types is the design of the upper control bearing.

The most common type was the 1 ″ threaded headset. Nowadays (2018) the 1⅛ ″ ahead tax rate is predominant. This is based on a patent from 1990 and was originally used on mountain bikes. The licensor of this patent was the American company Cane Creek.

Threaded headset

The threaded headset requires a steerer tube with an external thread at the top. In the classic 1 ″ headset, the inch thread with a pitch of 24 tpi is standardized in ISO 8488 (1986-06). There are deviations in historical tax rates, for example the French tax rate with the metric thread M25 x 1. From the 1-1 / 8 ″ tax rate, the thread pitch is 26 tpi. The top bearing shell (when using a cone bearing) or the fastening nut (when using an industrial bearing or cartridge bearing) is screwed on and secured with a lock nut. There is a washer in between. The steerer tube can be grooved in the area of the upper control bearing in order to insert a washer provided with a nose so that it cannot rotate. A brake cable counter holder for a central pull or cantilever brake can also be attached here.

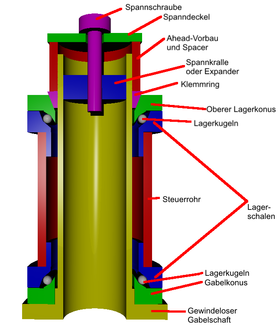

Ahead tax rate

With the Ahead system, there is no thread on the steerer tube. The headset is initially pre-tensioned during assembly by using a tensioning screw to exert pressure on the steering bearing over the not yet tightened handlebar stem. The nut for the clamping screw is driven into the steerer tube from above as a claw. The drive-in claw is a star-shaped stamped sheet metal part with a slight oversize, which expands in the shaft tube and carries the threaded nut for the clamping screw in the middle. For forks with a carbon shaft, an expander (cone expansion) must be used as the nut. After adjusting the bearing tension, the clamping screws of the handlebar stem on the upper end of the steerer tube are tightened, whereby the steering bearings are fixed in their pre-tensioned position by the external clamping of the stem. So that the clamping cover does not sit on the steerer tube, but rather enables the preload on the bearings, the end of the steerer tube protruding from the headset must be a little shorter (approx. 2 mm) than the height of the clamp fist of the stem including any spacer installed .

The ahead system is somewhat lighter than systems with a threaded headset. Assembly is easier and there is no need to stock forks with fork shafts of different lengths or recutting the thread on the fork shaft in production. However, the Ahead system only offers a poor option for adjusting the height of the stem . If there are spacers (spacer rings) between the stem and the upper part of the bearing, the spacers can also be inserted above the stem to lower it. In the case of steerer tubes made of steel, instead of the stem, an adapter part can be attached, which in turn accepts a height-adjustable stem.

Type of rolling bearing

The two control bearings are loaded both axially and radially, with the main load occurring in the axial direction. The rolling bearings are hardly moved. In the case of inaccurate installation (no flat supports, not aligned axes) this can lead to dents (chatter marks) on the raceway, as the load is then only distributed over a few rolling elements, which are always in the same place. In order to improve the load capacity, tapered roller or needle roller bearings were occasionally used, which are nowadays (2018) only rarely installed.

Originally only cone bearings were used in the headset, as well as on the wheel axles, pedals and bottom bracket. With the advent of encapsulated storage units on bicycles (e.g. cartridge chambers) in the 1970s and 1980s, industrial bearings were also used in the tax warehouse, referred to there as "cartridge bearings", although the conical bearing is still used extensively in the tax rate today (2018) .

Cone bearing

The cone bearing is the original form of the rolling bearing . This is an open, non-encapsulated (dismountable) rolling bearing. The housing consists of a cone (bearing cone) and a shell (bearing shell), which forms the running surface for the rolling elements in between.

As a rule, cone bearings are ball bearings. The balls can be loose (without a cage) or fixed by means of a cage. Cageless cone bearings are more resilient because more balls can be accommodated in the bearing. If tapered rollers or needles are used as rolling elements, a funnel-shaped cage is required.

At the lower control bearing, the cone pressed onto the steerer tube rests on the fork crown and is called the “fork cone”. Above this is a bearing shell pressed into the head tube. Depending on the version, a bearing cone or a bearing shell is pressed into the top of the head tube. These press fits require tight manufacturing tolerances.

Cartridge bearings

These are encapsulated and sealed ball bearings, mostly designed as angular contact ball bearings , occasionally also as deep groove ball bearings .

The outer ring of the bearing sits in a shell pressed into the head tube or - if a fully integrated head set ( IS or Integrated Standard ) is available - directly in the head tube. As a rule, the outer ring of the bearing on the contact surface to the head tube is beveled at an angle of 45 or 36 degrees; the corresponding counter contour is present in the head tube or the pressed-in shell.

The inner ring of the bearing rests on the fork crown on a cone-like centering ring (headset base, fork cone), which can be slotted or unslotted. A comparable cone-like centering ring (clamping ring) closes the headset at the top. The inner rings of the bearings are beveled accordingly on the contact surface with the two conical centering rings.

Installation position of the rolling bearings

Designation of the installation position according to the Standardized Headset Identification System (SHIS)

| EC | = External Cup (traditional): | The roller bearing is located in a shell outside the head tube | |

| ZS | = Zero stack (semi integrated): | The roller bearing is located in a shell inside the head tube | |

| IS | = Integrated Standard (fully integrated): | The roller bearing is located within the head tube without a shell |

Rolling bearings outside the head tube (EC)

This is the classic version. Shells are pressed into the ends of the head tube, which either serve as a direct bearing shell for a cone bearing or as a mounting bracket for a cartridge bearing. The roller bearings are located in the part of the pressed-in shells that protrudes from the head tube and thus enable a light head tube with a small diameter.

Rolling bearings within the head tube (ZS, IS)

The storage inside the head tube occurs practically only in bicycle frames made of aluminum or carbon. Since the head tube in the area of the control bearing has a relatively large diameter to accommodate the bearing, the control tube is usually tapered towards the center. In the version without a bearing shell ( IS or fully integrated ), the control tube has a widened inside diameter at both ends so that a cartridge bearing can be inserted there. In the version with a pressed-in inner bearing shell ( ZS or semi-integrated ), both a cartridge bearing and a cone bearing can be used.

SHIS

In November 2010, some bicycle parts manufacturers agreed on uniform names for the various headset sizes and types, the Standardized Headset Identification System (SHIS).

The designation is basically in two parts, the first part describing the upper and the second part the lower bearing. In between is a vertical dividing line. The two names begin with an identifier of the storage type, namely EC for external cups (external cup), ZS for semi-integrated cups (zero stack) and IS for fully integrated cups. This is followed by the rounded, metric diameter of the bearing shell with two digits, a slash and the diameter of the steerer tube for the stem clamp (above) or the diameter of the lowest part of the steerer tube for the bearing cone that is placed on the fork or struck.

Example 1: ZS44 / 28.6 | ZS44 / 30 means: The upper bearing shell is semi-integrated and has a diameter of 43.95 to 44.00 mm; the steerer tube has a diameter of 28.6 mm at the top (i.e. where the stem is clamped). The lower bearing shell is also semi-integrated and also has a diameter of 43.95 to 44.00 mm. The lowest part of the steerer tube, where the bearing cone is attached or opened, has a diameter of 30 mm.

Example 2: ZS44 / 28.6 | ZS56 / 40 means: The upper bearing shell is semi-integrated and has a diameter of 43.95 to 44.00 mm; the steerer tube has a diameter of 28.6 mm at the top (i.e. where the stem is clamped). The lower bearing shell is also semi-integrated and has a diameter of 55.90 to 55.95 mm. The lowest part of the steerer tube, where the bearing cone is fitted or opened, has a diameter of 40 mm. It is therefore a tapered tax rate.

The identification of thread tax rates looks different and always contains the identifier "tpi" (threads per inch, threads per inch).

literature

- Michael Gressmann, Franz Beck, Rüdiger Bellersheim: specialist knowledge of bicycle technology. 1st edition. Verlag Europa-Lehrmittel, Haan-Gruiten 2006, ISBN 3-8085-2291-7 .

- Fritz Winkler, Siegfried Rauch: Bicycle technology repair, construction, production. 10th edition. BVA Bielefelder Verlagsanstalt, Bielefeld 1999, ISBN 3-87073-131-1 .

- Rob van der Plas: The bicycle workshop - repair and maintenance step by step. 1st edition. BVA Bielefelder Verlaganstalt, Bielefeld 1995, ISBN 3-87073-147-8 .

Web links

Individual evidence

- ↑ Headset to Bicycle Fit Specifications (9/11/2008). Cane Creek Web site, accessed August 18, 2018.

- ↑ Patent US5095770 : Steering bearing assembly for wheeled vehicle. Published March 17, 1992 , Inventor: Homer J. Rader.

- ↑ Article about the invention of the ahead tax rate. Retrieved August 18, 2018.