Sulphate process (titanium dioxide)

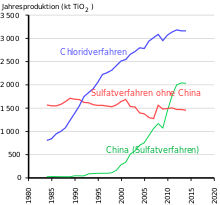

The sulphate process was developed in 1915 by the Norwegians F. Farup and Dr. G. Jebsen developed process for the production of titanium dioxide . It has been in commercial use since 1916 and is still relevant today.

Procedural steps

The finely ground and enriched titanium iron ore ilmenite is digested with concentrated sulfuric acid . The iron oxide contained in the ore reacts to form iron sulfate , the titanium ore to titanium oxide sulfate TiOSO 4 .

The raw material ilmenite, formally FeTiO 3 , is converted with concentrated sulfuric acid to iron sulfate and titanium oxide sulfate. Since the iron is partially trivalent as Fe 3+ , the digestion solution must be mixed with pure iron scrap as a reducing agent in order to obtain exclusively bivalent iron Fe 2+ . This can then be crystallized out of the solution as so-called green salt .

The titanium oxide sulfate remaining in solution can be precipitated and separated off as a sparingly soluble titanium oxide hydrate by hydrolysis . After several filtration and washing processes, the titanium oxide hydrate has to be calcined at 800-950 ° C in order to obtain titanium dioxide.

By adding seed crystals and using the temperature, it is possible in this step to control the modification in which the TiO 2 is to be produced. The sulfate process is suitable for the production of both the anatase and rutile modifications, while the chloride process is generally only used for the production of pure rutile.

Web links

- Titanium dioxide with the sulfate process into the next millennium ( Memento from September 24, 2006 in the Internet Archive ) (PDF; 706 kB)