Original value card

The original value card is a variant of the quality control cards (QRK) that is used in quality management to evaluate test data. It serves as an aid for statistical process control (SPC).

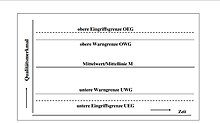

On the original value map, statistical sample values are graphically displayed over time and warning and action limits are drawn.

Original value cards serve the purpose of checking whether the expected value and the spread of the characteristic under consideration are the same as the relevant given or known or estimated values in the case of an undisturbed process. So it shows the location and the spread in a track.

The prerequisite for using this quality control card is that the process is approximately normally distributed. The original value card is used when only a few values are available, or as a preliminary stage to the regular quality control card (QCC). Original values can be: all measured values, mean values, standard deviations or ranges.

Structure of the original value card

Basically, the structure of the original value card is always the same as the other quality control cards. It is structured roughly like a coordinate system:

On the horizontal axis (x-axis, abscissa), the number of the sample, the time at which the sample was taken or other information that can be clearly assigned to the sample is plotted alternatively. The quality feature that must be checked is plotted on the vertical axis (y-axis, ordinate). The quality features are mostly the measurement results or the values of the sample.

The mean value calculated from the preliminary examinations is entered as the center line (M) . The center line therefore represents the process mean value µ .

Sensible warning and action limits are also set. Two limits are defined in each case, an upper and a lower limit, which should have the same distance from the center line.

Lower and upper control limit (UEG and LEL):

If a value falls below or exceeds a control limit, action is taken. This means that if the entered maximum or minimum values are exceeded or not reached, the cause must be investigated and the process corrected if necessary. The calculation of the control limits is based on the 99% random scatter range ”

Lower and upper warning limit (OWG and UWG):

If a value falls below or exceeds a warning limit, i.e. if the entered maximum or minimum values are exceeded or fallen below, the process must be observed with increased attention. The calculation of the warning limits is based on the 95% random scatter range ”

Keeping an original value card

In the original value card, random samples of a certain scope are taken at regular intervals. As with any quality control chart, you should choose a suitable sample size (s) and a reasonable time interval . The sample must have a fixed number of at least 5. So random samples of five measured values each are entered.

Now the actual exact mass of the parts from the sample is marked with a point in the sample columns. If certain values occur frequently, they are given the same values and a frequency number that can provide information about recurring errors.

After the random samples have been checked regularly and all n measured values have been entered one above the other, you proceed through the position of the entered measured values in relation to the warning and action limits as follows:

- If a sample value is within the warning limit, the production process is undisturbed. No intervention is necessary.

- If a sample value lies between the warning and action limits, there is a suspicion of a disruption in the process. The manufacturing process is now subject to increased attention. Therefore, another sample is taken immediately.

- If a sample value is outside the control limits, the manufacturing process is disrupted and intervention is necessary. The measures that must be taken depend on what knowledge is available about the process to be controlled and the type of fault displayed.

“With the original value card, the characteristics of the characteristic of all parts of a sample are plotted on the same horizontal position. This means that outliers, but also large variations, can be easily made visible. The values of the characteristics of the individual parts are also retained for subsequent evaluations. "

The original value card simultaneously monitors location and spread, which is why it is not necessary to keep an s card . However, it can only show an increase in the standard deviation σ . The limits are set in such a way that all the original values of a random sample of size n taken from the unchanged process lie within the control limits with a probability of 99% and within the warning limits with a probability of 95%.

Invoice of the original value card

The original value map reacts sensitively to a change in the expected value µ and the standard deviation σ. If the feature values are approximately normally distributed and the process mean value µ is constant, the position and spread can be monitored with original values.

The limit values are calculated using the quantiles of the normal distribution. The limits and the center line of an original value QRK are to be determined as follows:

The expected value µ and the standard deviation σ are given or known or estimated by a preliminary run. E E and E W are constants and can be calculated from the distribution function of the normal distribution.

Intervention characteristics from original value quality control card

If the process parameters (position and spread) change, the probabilities of exceeding the warning and action limits also change.

To determine the probability of intervention (1 - P a ) as a function of the shift in the position from µ to µ t by Δµ = µ t - µ and the change in the spread of the distribution from σ to σ t , you proceed as follows:

The probability P that an original value lies within the control limits with the mean value shifted by Δµ and with the scatter increased to σ t

P = G (u ob ) - G (u un )

with G (u) = distribution function of the standardized normal distribution

The following applies to the control limits:

where for u ob and u un follows

Because of Pa = P n

Two cases are described in more detail below:

- Scatter constant and position shifted (case (1))

- Scatter changed and position constant (case (2))

Case (1): , Δμ ≠ 0

In this case, the following applies to the probability of intervention

Case (2): Δµ = 0;

In this case, the following applies to the probability of intervention

Acceptance quality control card for original values

An acceptance quality control card can also be constructed as an original value card.

The original value card is created in such a way that the control limits comprise 75% of the tolerance, because inexpensive production is only possible if the production limits use a maximum of 75% of the tolerance.

Tolerance limits are upper limit value ( OGW ) and lower limit value ( UGW ). As a rule, they are not drawn on process control cards, since they apply to characteristic values and not to the parameters shown on the control cards. The following applies:

Center line

Upper control limit OEG = OGW - k E · σ

Lower control limit LEL = UGW + k E · σ

k E is the delimitation factor that is calculated for original values with an assumption QC:

Pa = non-intervention probabilities

The excess portions only occur at the lower or upper control limit. The probability of intervention of the acceptance QCC for original values is calculated as:

The margin S of the original value acceptance quality control card is:

There are:

T = tolerance range

T o, x = requirement of the tolerance range that is required by the original value card itself.

Advantages of the original value card

The original value card monitors the process mean value and the process spread at the same time. All measured values are entered and thus documented.

The original value card has a direct reference to the process results. No calculations are required to keep an original value card. Therefore, a process can be monitored immediately after the original values have been entered without an invoice. The original value control card is very easy to keep and little handling is required.

Another advantage is that the systematic influences on the process can be recognized very well.

Disadvantages of the Urwerkarte

Monitoring the process with an original value card exposes the feature values to be approximately normally distributed, which is not necessarily realistic.

The original value card has low sensitivity. For example, it reacts significantly less sensitive to changes in the position of the process mean value than the median track or the mean value track.

If there are many measured values, this can lead to poor selectivity, because it is easy to confuse control limits and warning limits. The statistical information is relatively small.

Using the original value card

Because of its disadvantages, the original value card is not always recommended as a quality control card. However, their use is recommended in exceptional cases. It is recommended, for example, only when a process control is introduced, only for the first steps, for example in the form of self-examination. It can therefore be created as a preliminary stage for more complex control charts.

If only a few values are recorded, for example only the length or only the diameter of a workpiece, the original value card is also used to graphically display the process results.

literature

- Gerhard Linß: Quality management for engineers. 3rd, update Hanser, Carl, Munich 2009

- Edgar Dietrich: Statistical procedures for machine and process qualification. 6., completely revised Hanser, Carl, Munich 2008

- Hans-Joachim Mittag: Quality control cards. Hanser, Munich 1993

- Benes / Groh: Basics of quality management. 4th edition. Munich

- German Society for Quality Working group on quality control cards : SPC 2 - Quality control card technology. 4th edition Beuth, Berlin 1992

- Klaus Bernecker: SPC 3 - Instructions for statistical process control (SPC): Quality control cards, process capability assessments (Cp, Cpk), error collection card. 1st edition Beuth, Berlin 1990

- Walter Masing, 1915-2004, Pfeifer, Tilo 1939-, Schmitt, Robert .: Masing handbook quality management. 6., revised. Hanser, Munich 2014

- Hans-Joachim Mittag: Statistical Methods of Quality Assurance. 3rd, revised. Hanser, Munich 1995

- Michael Marxer: Production metrology practice-oriented principles, modern measuring methods. 8th, completely revised u. exp. Edition Springer Fachmedien Wiesbaden, Wiesbaden 2015

- Wolfgang Timischl: Quality assurance: statistical methods; with 19 tables. 3rd, revised. Hanser, Munich 2002

- Claus Morgenstern: Practical Guide Six Sigma: Project Selection, Process Optimization, Zero Defect Quality / [1] [basic work]. WEKA Media, Kissing 2004

Individual evidence

- ↑ a b c d e f g h i j k l Linß, Gerhard .: Quality management for engineers . 3rd, update Edition Hanser, Carl, Munich 2009, ISBN 978-3-446-41784-7 .

- ^ Dietrich, Edgar .: Statistical procedures for machine and process qualification . 6., completely revised Edition Hanser, Carl, Munich 2008, ISBN 3-446-41525-4 .

- ^ Mittag, Hans-Joachim .: Quality control cards . Hanser, Munich 1993, ISBN 3-446-17661-6 .

- ↑ a b c d Benes / Groh: Basics of quality management . 4th edition. Munich 2017, ISBN 978-3-446-45269-5 .

- ↑ a b c d German Society for Quality Working group on quality control cards : SPC 2 - Quality control card technology . 4th edition Beuth, Berlin 1992, ISBN 3-410-32827-0 .

- ↑ a b c d Bernecker, Klaus .: SPC 3 - Instructions for statistical process control (SPC): quality control cards, process capability assessments (Cp, Cpk), error collection card . 1st edition Beuth, Berlin 1990, ISBN 3-410-32821-1 .

- ↑ Masing, Walter 1915-2004, Pfeifer, Tilo 1939-, Schmitt, Robert .: Masing handbook quality management . 6., revised. Edition Hanser, Munich 2014, ISBN 3-446-43431-3 .

- ↑ a b Mittag, Hans-Joachim .: Statistical methods of quality assurance . 3rd, revised. Edition Hanser, Munich 1995, ISBN 3-446-18006-0 .

- ↑ a b Marxer, Michael .: Production metrology practice-oriented principles, modern measuring methods . 8th, completely revised u. exp. Edition Springer Fachmedien Wiesbaden, Wiesbaden 2015, ISBN 978-3-8348-2582-7 .

- ↑ Timischl, Wolfgang .: Quality assurance: statistical methods; with 19 tables . 3rd, revised. Edition Hanser, Munich 2002, ISBN 3-446-22053-4 .

- ↑ Morgenstern, Claus .: Practical Guide Six Sigma: Project selection, process optimization, zero defect quality / [1] [basic work]. WEKA Media, Kissing 2004, ISBN 3-8111-3330-6 .

![{\ displaystyle OEG (x) = \ mu + E_ {E} * \ sigma = \ mu + u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/664bb555ada3ce3769c3715646e3459251f6d1d7)

![{\ displaystyle OWG (x) = \ mu + E_ {W} * \ sigma = \ mu + u _ {\ frac {1 + {\ sqrt [{n}] {0.95}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/24614e12f12cdfed32b85871a84c5fadacccc199)

![{\ displaystyle UWG (x) = \ mu -E_ {W} * \ sigma = \ mu -u _ {\ frac {1 + {\ sqrt [{n}] {0.95}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/8dfe7b7d49822cc258f7625ea9bd9559bfba5403)

![{\ displaystyle LEL (x) = \ mu -E_ {E} * \ sigma = \ mu -u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/955f4b78ceb54776e65d33a1dec843eeb8449207)

![{\ displaystyle OEG (x) = \ mu + u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/96df7f834735eed11e3086d84d5fd2df2358b7d2)

![{\ displaystyle LEL (x) = \ mu -u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma}](https://wikimedia.org/api/rest_v1/media/math/render/svg/faa7c1994b443b43c5c3190ae5e8d67f3f1cb521)

![{\ displaystyle u_ {ob} = {\ frac {u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma - \ vartriangle \ mu} {\ sigma _ {t}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/08791d5c4417f8ffccac532a7309f395ed241ee8)

![{\ displaystyle u_ {un} = {\ frac {-u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma - \ vartriangle \ mu} {\ sigma _ {t}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/0c44350a079a834b0f9bc1843da42efb2dc31978)

![{\ displaystyle Pa = {\ Biggl (} G {\ Biggl (} {\ frac {u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * \ sigma - \ vartriangle \ mu} {\ sigma _ {t}}} {\ Biggr)} - G {\ Biggl (} {\ frac {u _ {\ frac {1 + {\ sqrt [{n}] {0.99} }} {2}} * \ sigma + \ vartriangle \ mu} {\ sigma _ {t}}} {\ Biggr)} {\ Biggr)} ^ {n}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/7b7e0fb03f1e50afd980f005bec8ff83291489c1)

![{\ displaystyle 1-Pa = 1 - {\ Biggl (} G {\ biggl (} u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} - {\ frac {\ vartriangle \ mu} {\ sigma}} {\ biggr)} - G {\ biggl (} -u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} - {\ frac {\ vartriangle \ mu} {\ sigma}} {\ biggr)} {\ Biggr)} ^ {n}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/fdd8aee4b9209b134a658813ebfeb4d1759e9f3c)

![{\ displaystyle 1-Pa = 1 - {\ Biggl (} G {\ biggl (} u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}} * {\ frac {\ sigma} {\ sigma _ {t}}} {\ biggr)} - G {\ biggl (} -u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2 }} * {\ frac {\ sigma} {\ sigma _ {t}}} {\ biggr)} {\ Biggr)} ^ {n}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/cb4e440fae7559b685a3495d428a063e4fdca647)

![{\ displaystyle k_ {E} = u_ {1-P} -u _ {\ sqrt [{n}] {Pa}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/25e4211c36ba36bb3f4ff83e01dd5b22e50daaab)

![{\ displaystyle 1-Pa = 1- [G (u_ {1-p} -k_ {E})] ^ {n}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/3338e9396c6928b6d8d37389548fe0a9d36602bf)

![{\ displaystyle T_ {o, x} = (2 * k_ {E} + 2 * u _ {\ frac {1 + {\ sqrt [{n}] {0.99}}} {2}}) * \ sigma }](https://wikimedia.org/api/rest_v1/media/math/render/svg/983e960de19b27cbe593bfd967b23da893ad417e)