Vortex separator

A vortex separator is a waste water treatment system in the form of a round unit, in which the waste water is introduced tangentially. A distinction is made between vortex separators for rainwater treatment, in which only sediments can be separated by sinking, and vortex separators for the treatment of industrial wastewater, in which light liquids (e.g. oil) and sediments up to a particle size of 5 µm can be separated simultaneously.

Vortex separators for industrial wastewater

Working principle

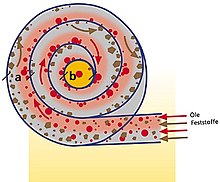

The functional principle of the vortex separator is based on the different flow behavior of light liquids (e.g. oil, diesel, gasoline) with water and the difference in density between these organic components and any sediments contained in the liquid (e.g. sand). Thereby act centrifugal and centripetal forces on the water-oil-sand mixture and separate the substances from each other. This vortex separator is a further development of the conventional oil and gasoline separator or the coalescence separator . The system only needs a gradient of approx. 10 cm for energy. The system offers a blockage-free passage that is larger than 60 mm. In the vortex separator, a total of four different laws of nature are used in one system:

- The centrifugal and centripetal force: while heavy particles move centrifugally outwards to the edge of the baffles and settle, light liquids simultaneously flow towards the center, towards the inner walls, i.e. directed centripetally.

- The adhesive power: While the outer walls of the spiral system are oil-repellent, the inner wall is coated with an oil-attracting material composition. The smallest oil droplets, which are already moving towards the inner wall due to the centripetal force, are additionally attracted and sometimes adhere to the guide wall for a short time.

- The pulsating force: The different distances between the walls in the spiral create the desired pulsating flow - through slow and faster flow movements - which optimally supports the coalescence effect of the oil droplets.

- Circulation and vortex coalescence: With vortex separators, the oils collect in the middle (analogous to the foam when stirring in a cup). There the oils are drawn off from the surface using a funnel. The vortex energy creates a vortex depression and a suction effect in the middle.

Areas of application

The vortex separator can be used wherever light liquids and / or suspended particles have to be separated from the water. The vortex separator is used, for example, for the effective cleaning of surface water, especially large operating areas (contaminated rainwater at airports, refineries, sea and inland ports, scrap yards, etc.) or as a preliminary stage in the treatment of industrial process and service water . In terms of volume, the vortex separator can usually be designed to be significantly smaller than conventional separators. The vortex separator achieves a cleaning performance of less than 5 mg / l.

literature

- Friedhelm Sieker u. a .: Near-natural rainwater management in settlement areas . 3. Edition. Expert-Verlag, 2003, ISBN 3-8169-2279-1 , pp. 81 ( limited preview in Google Book search).